- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

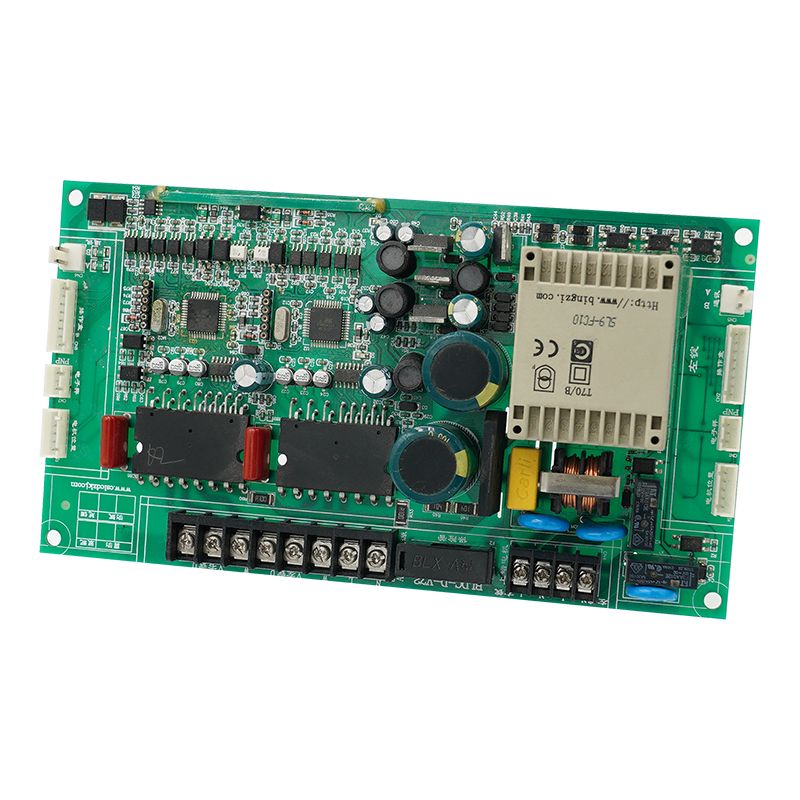

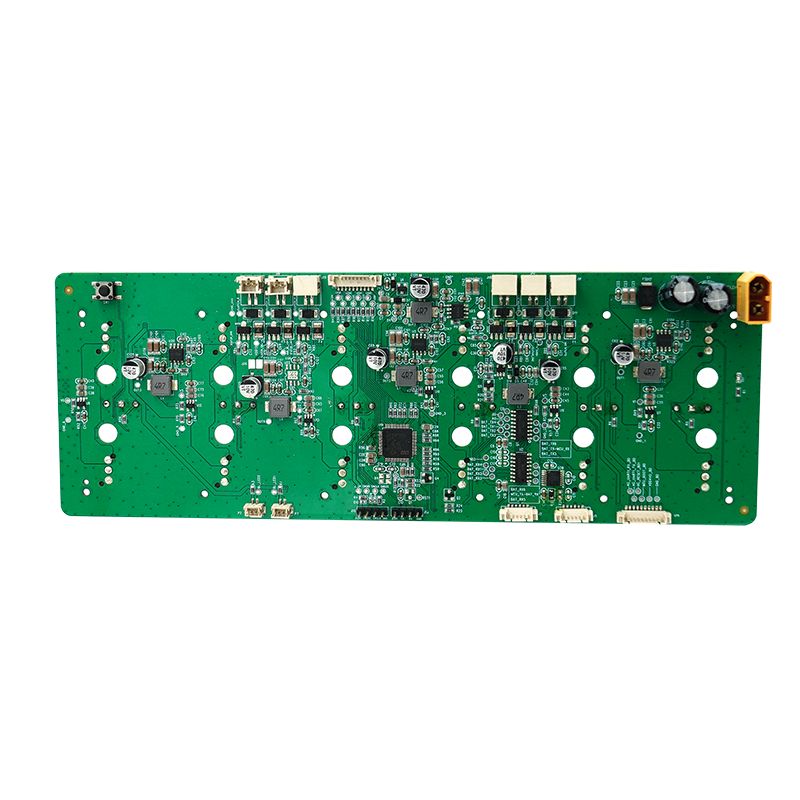

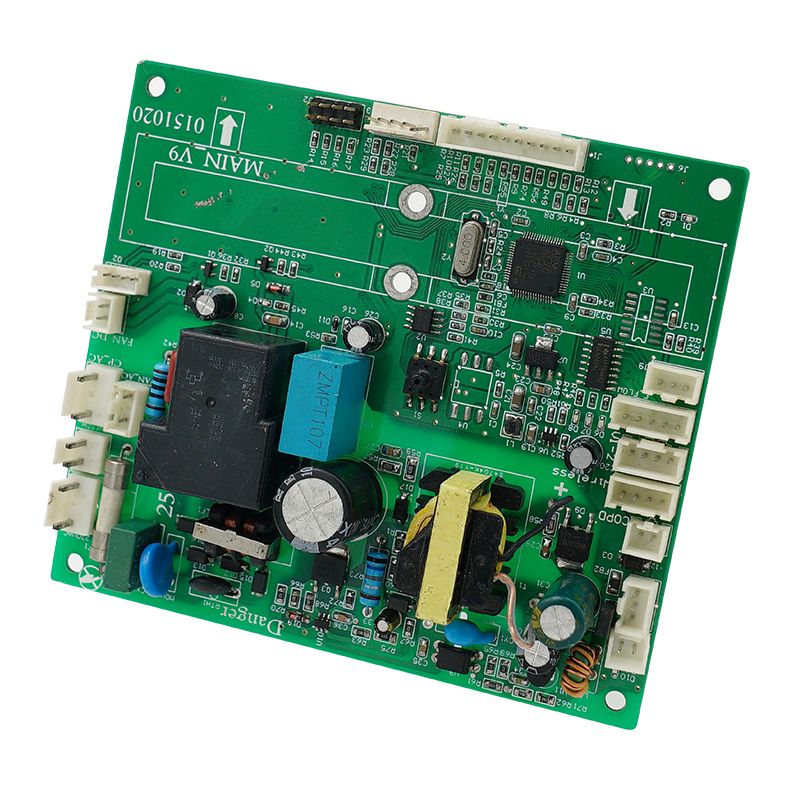

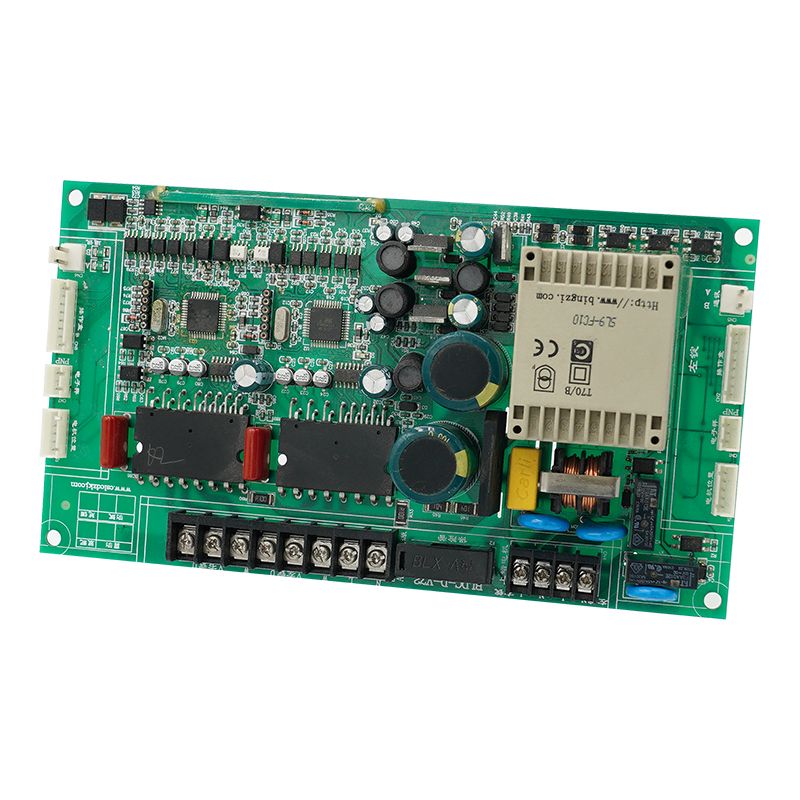

Soymilk Maker PCBA

Send Inquiry

Product Positioning

In traditional soy milk makers, the control board is mainly responsible for basic heating and motor drive. This Soymilk Maker PCBA, however, was designed from the outset around "intelligence + user experience":

Bringing soy milk makers online, entering the IoT era

Allowing users to truly participate in the production process through an app or the cloud

Making it easier for brands to differentiate their products, rather than competing on price

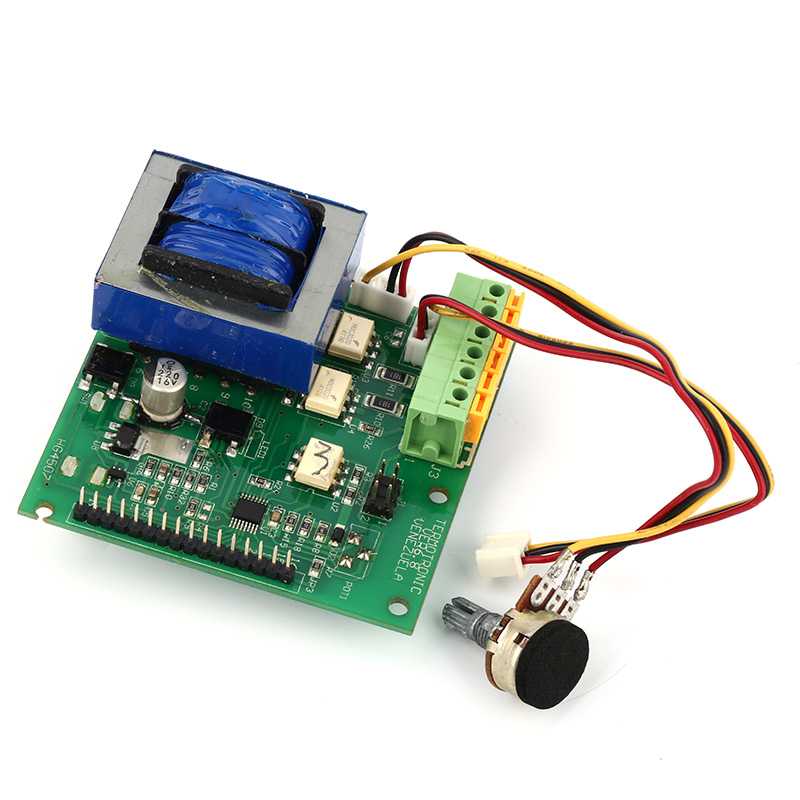

Core Function Design

1. IoT Remote Control, for greater freedom of use

Through wireless communication methods such as Wi-Fi, Bluetooth, NB-IoT, or Zigbee, users can achieve:

Remote power on/off

Real-time viewing of working status and temperature

Remote scheduling of soy milk production time

Automatic alarm for abnormal operation

For busy modern families, this is not just "showing off technology," but genuine convenience.

2. Intelligent Temperature Control and Status Monitoring, for more consistent taste

The control board integrates multiple sensor interfaces, allowing for real-time data collection of:

Heating temperature

Operating stage

Motor load status

Through algorithm optimization, it achieves precise temperature control and a stable heating curve, making the taste of every cup of soy milk more consistent and reducing problems such as burning or undercooking.

3. Recipe and Program Management

The PCBA supports various program and recipe logic designs, such as:

Classic soybean milk

Multigrain soy milk

Filter-free/high-speed blending mode

Customizable time and temperature curves

Brands can define product differentiation through software, allowing the same hardware to create multiple models and price levels.

Hardware Design Philosophy

• Highly integrated main control chip + wireless module

Optimized layout of wireless communication module and main control MCU

Reduced signal interference, improved network stability

Balanced power consumption control to avoid unnecessary energy waste

• Power supply design tailored to home appliance scenarios

Fully considers the instantaneous power consumption of the wireless module

Supports long-term stable operation

Compatible with various power supply solutions for different market applications

Software and Firmware

Supports mainstream communication protocols such as MQTT and HTTP

Real-time data acquisition and upload

Fault diagnosis and status feedback

Supports OTA firmware upgrades

Prioritizing data security and system stability

Authentication mechanism

Encrypted data transmission

Prevents unauthorized control and system attacks

This is especially important for export products and smart home appliance brands.

Cloud Platform & App Experience

The control board can seamlessly connect to:

Self-built cloud platform

Third-party cloud services

Brand-specific App or Web control interface

Users can:

View historical usage records

Set personalized preferences

Manage multiple devices

From hardware to the cloud, forming a complete smart soy milk maker ecosystem.

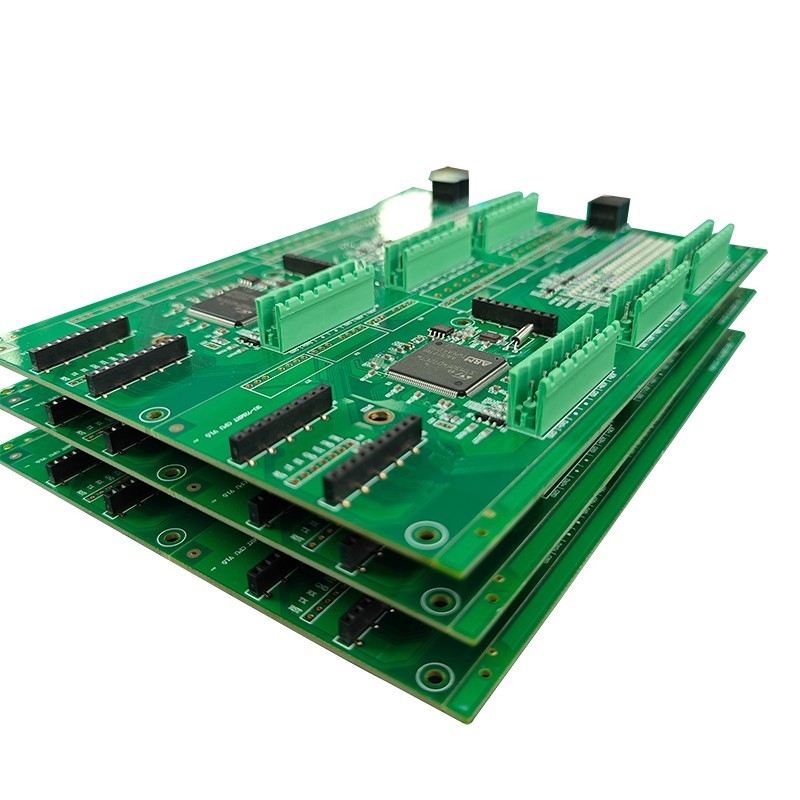

Home Appliance PCBA

Industrial Control PCBA

Automobile PCBA

Consumer Electronics PCBA

Medical Equipment PCBA

Security System PCBA

Healthcare PCBA

LED Lighting PCBA

IoT PCBA

Electric Gardening Tool PCBA

-

Delivery Service

-

Payment Options