- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

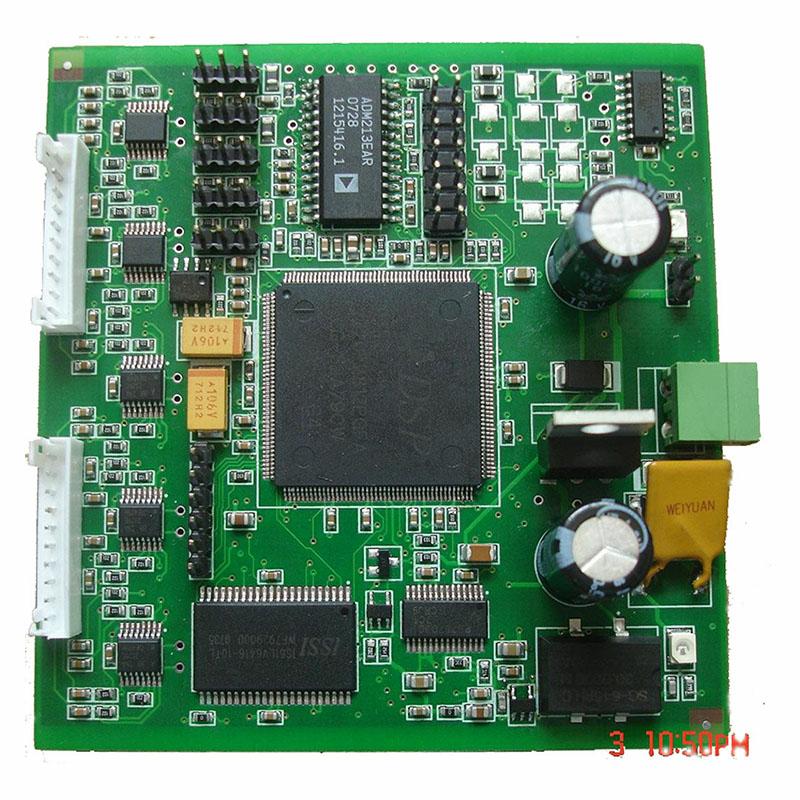

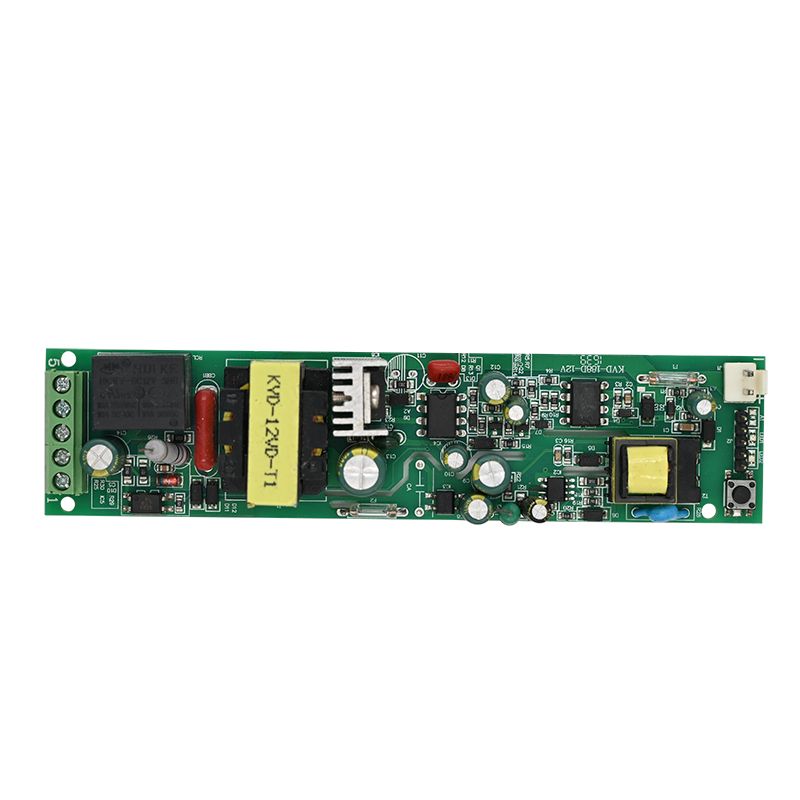

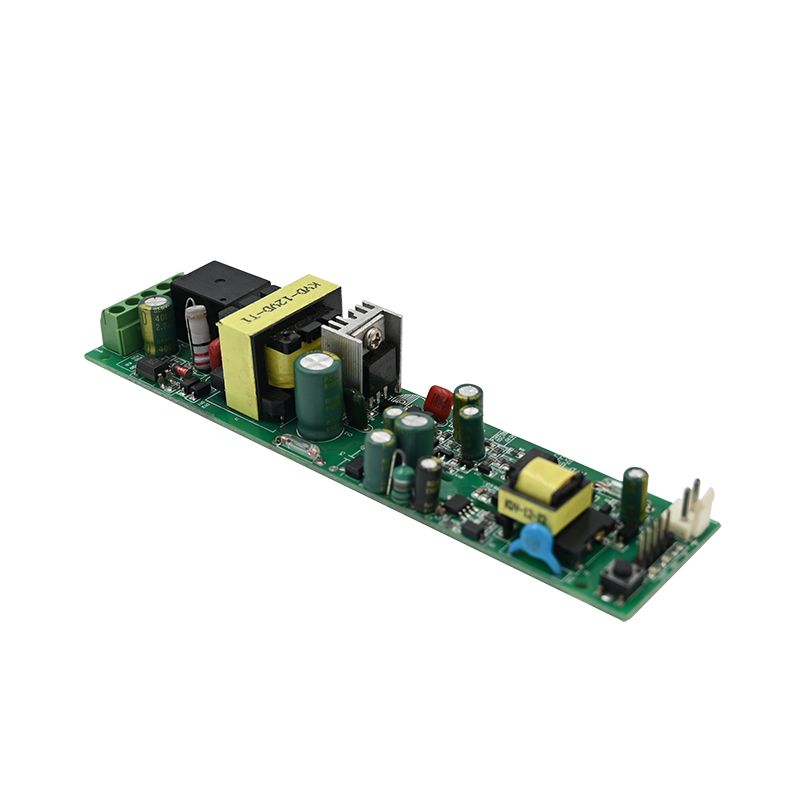

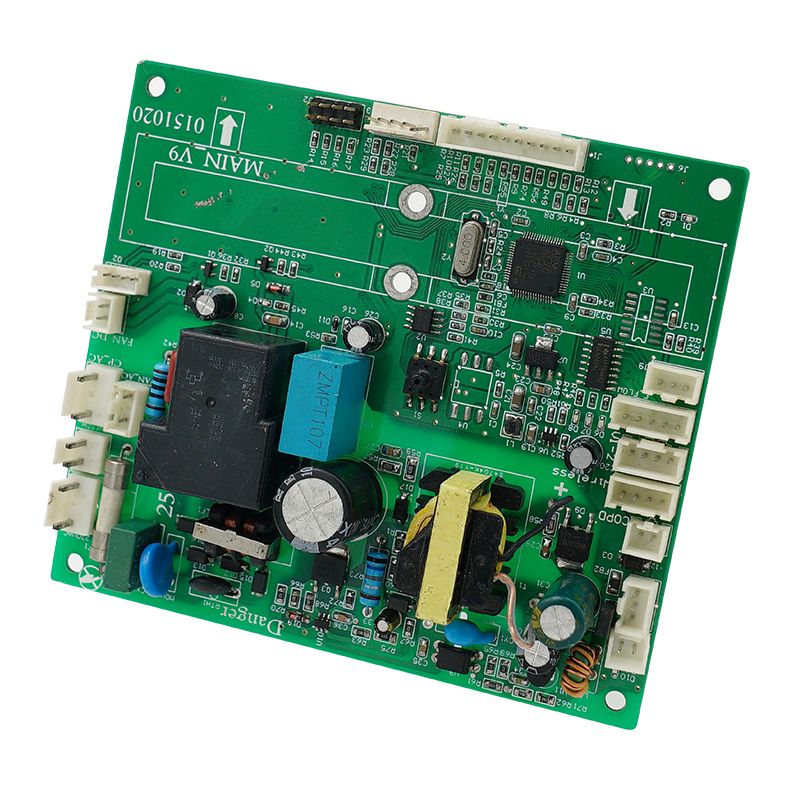

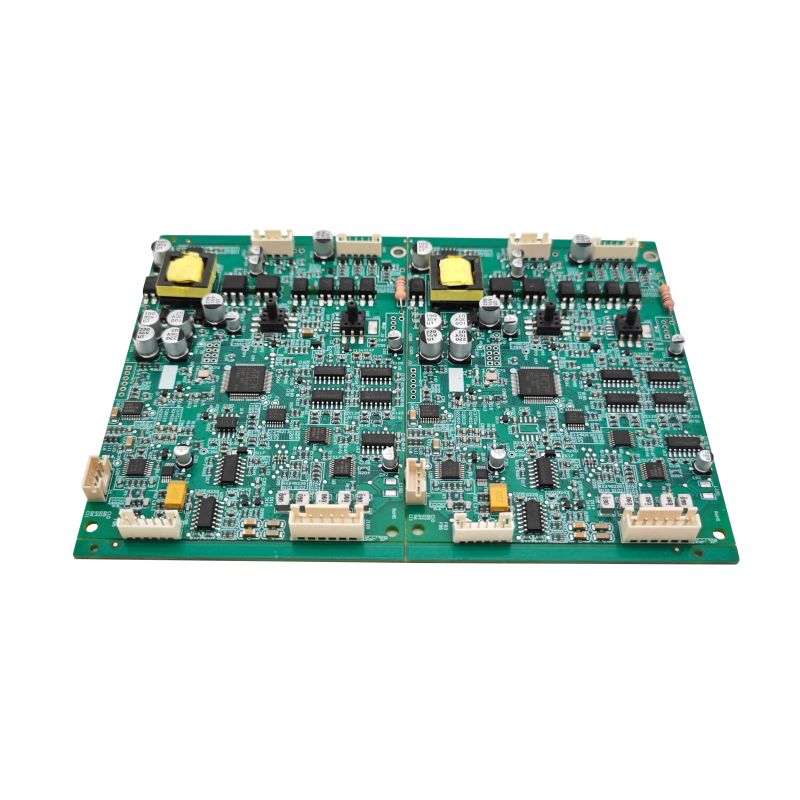

coffee machine PCBA

Send Inquiry

Multilayer Board Applications in Coffee Machine PCBA

Multilayer board designs for Coffee Machine PCBA from Unixplore Electronics offer greater layout space and more complex circuit connections, making them suitable for control systems requiring the integration of multiple functions and components. Here are some advantages and functions of multilayer board applications in Coffee Machine PCBA:

Dense Layout: Multilayer board designs allow for dense component placement, saving space and increasing circuit layout flexibility, making them particularly suitable for complex control system designs.

Signal Integrity: Multilayer boards provide better signal integrity, reducing crosstalk and interference during signal transmission, ensuring the stability of high-frequency signal and data transmission.

Power Supply Layering: Multilayer boards allow for layered arrangement of power and ground lines, reducing circuit interference and noise, and improving system stability and anti-interference capabilities.

Thermal Management: Multilayer board designs facilitate heat conduction and dissipation, helping to control the internal temperature of the coffee machine, protecting components and extending equipment life.

Multifunctional Integration: Multilayer boards can accommodate more functional modules and interfaces, enabling multifunctional integrated designs, giving Coffee Machine PCBA more functionality and expandability.

Production Efficiency: The high degree of automation in multilayer board production processes reduces manual soldering and assembly steps, improving production efficiency and quality stability.

System Reliability: The multi-layer board design improves the stability and reliability of the entire coffee machine control system, reducing failure rates and maintenance costs.

By applying a multi-layer board design, the Coffee Machine PCBA can leverage more functions and performance advantages, improving overall system performance and stability, and providing users with a better coffee brewing experience.

Home Appliance PCBA

Industrial Control PCBA

Automobile PCBA

Consumer Electronics PCBA

Medical Equipment PCBA

Security System PCBA

Healthcare PCBA

LED Lighting PCBA

IoT PCBA

Electric Gardening Tool PCBA

-

Delivery Service

-

Payment Options