- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

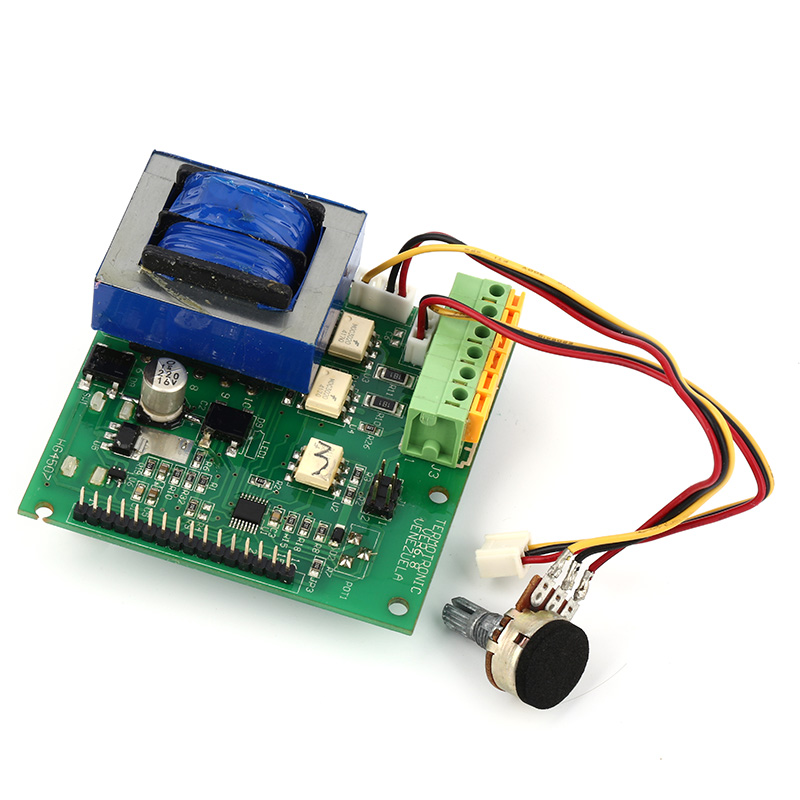

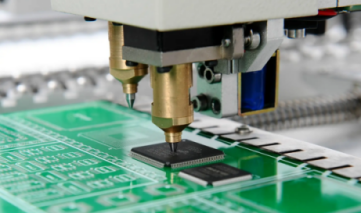

Eletric Heater PCBA

Send Inquiry

There are several PCBA cleaning methods during PCBA manufacturing process

PCBA cleaning methods are mainly divided into the following five categories, selected based on the degree of contamination, component type, and cost requirements:

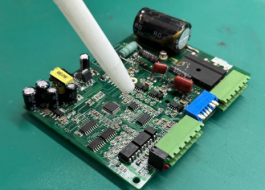

How to do it: Take a small brush, dip it in some PCB cleaning solution, and scrub with your bare hands.

Advantages: Simple and straightforward, clean only the dirty areas, no need to buy large equipment.

2. Ultrasonic Cleaning

How it works: Soak the board in a cleaning solution, and use high-frequency vibration to "vibrate" out the dirt from the crevices.

Advantages: Cleans even hard-to-reach areas, and is highly efficient.

3. Spray/Water Stream Cleaning

How it works: The machine uses a high-pressure water gun to spray the board vigorously.

Advantages: Suitable for high-volume production lines, highly automated, and saves labor.

4. Dry Ice Cleaning

How it works: Spray out a bunch of small dry ice particles to "freeze" away the dirt.

Advantages: Extremely clean and leaves no moisture, very gentle on precision parts, and very environmentally friendly.

5. No-clean technology

How to do it: Use a high-tech flux that eliminates the need for cleaning after soldering.

Advantages: The most cost-effective and fastest method, eliminating an entire process step.

Which method is more suitable?

Small jobs, low requirements: Brush cleaning (manual) or ultrasonic cleaning.

High requirements, expensive parts: Choose dry ice cleaning, or use no-clean materials.

Large orders, tight deadlines: An automated spray cleaning line is necessary.

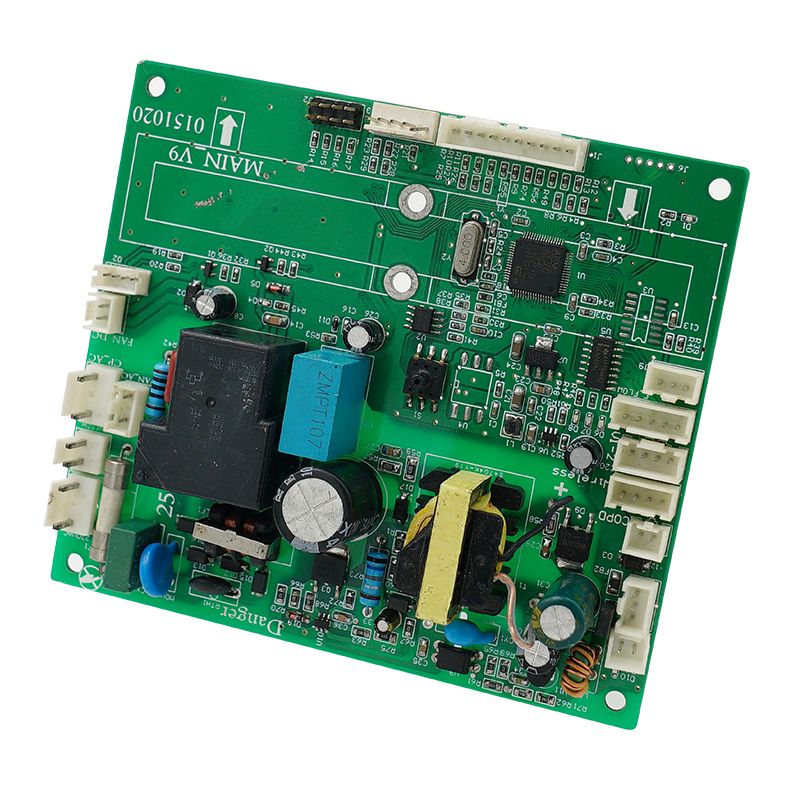

Home Appliance PCBA

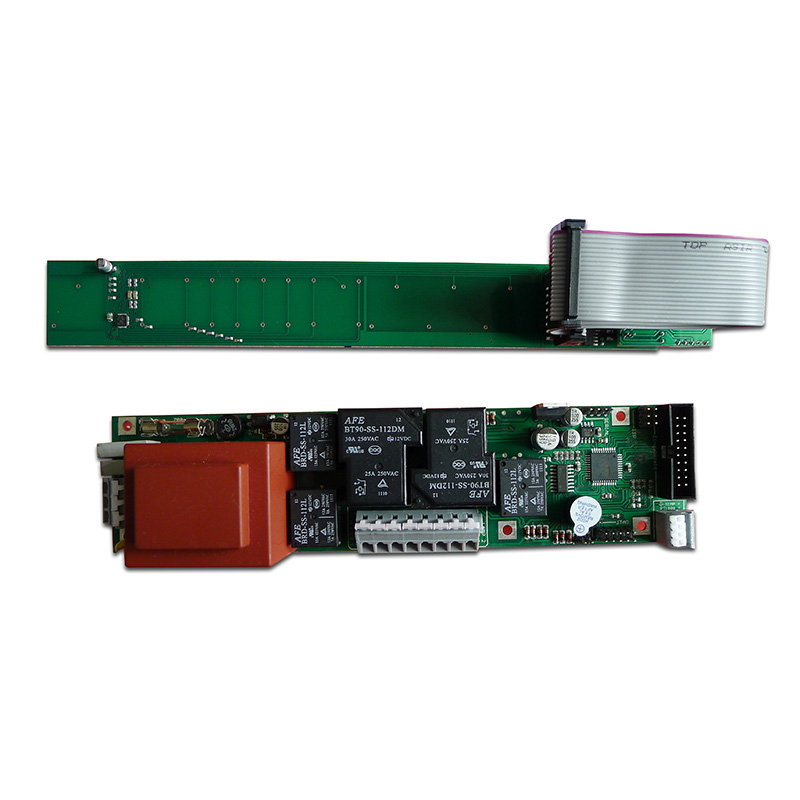

Industrial Control PCBA

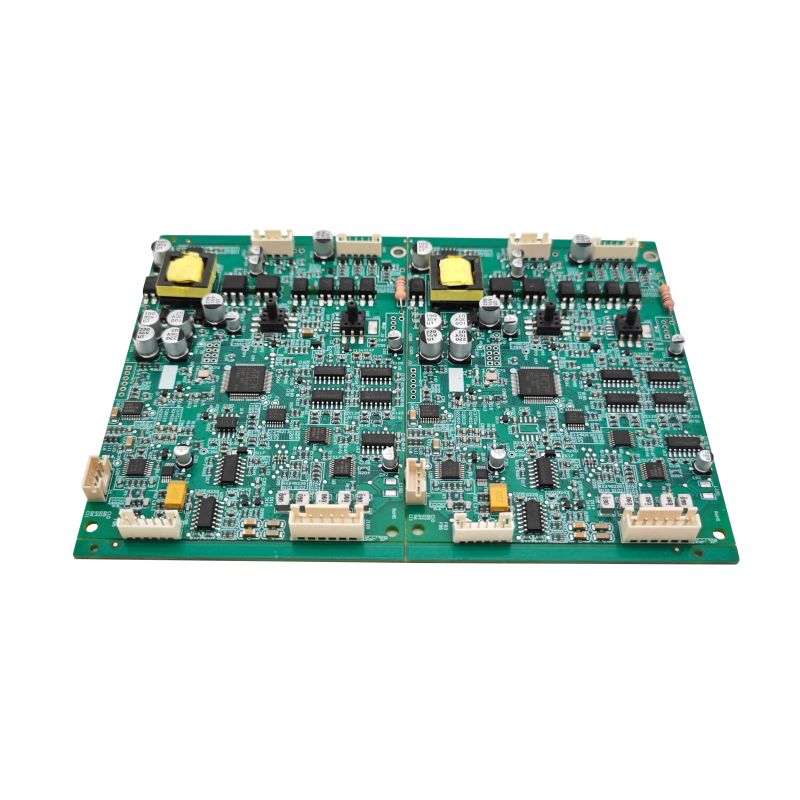

Automobile PCBA

Consumer Electronics PCBA

Medical Equipment PCBA

Security System PCBA

Healthcare PCBA

LED Lighting PCBA

IoT PCBA

Electric Gardening Tool PCBA

-

Delivery Service

-

Payment Options