- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can advanced testing technologies ensure product quality at Alarm System PCBA factories?

In alarm system PCBA (Printed Circuit Board Assembly) manufacturing, ensuring product quality is crucial. Advanced testing technologies play a key role in this process, performing comprehensive inspections on circuit boards to ensure that each product meets design and quality standards. This article will explore how advanced testing technologies can improve product quality at PCBA factories.

1. Automated Optical Inspection (AOI)

Function and Application

Automated Optical Inspection (AOI) is a technology that uses high-resolution cameras to perform visual inspections on alarm system PCBAs. AOI systems can quickly scan circuit boards to check for issues such as solder joints, component placement, and missing components. By comparing actual images with standard images, AOI can promptly detect defects during the production process.

Advantages

The advantages of AOI technology lie in its high efficiency and accuracy. Compared to manual inspection, AOI can detect even small defects faster and more accurately, and it is not susceptible to fatigue. This allows factories to detect problems early on in the production line, reducing the number of defective products.

2. X-ray Inspection (AXI)

Function and Application

X-ray inspection (AXI) technology is used to inspect solder joint quality within PCBAs, particularly for defects that are difficult to detect from the surface, such as BGA (ball grid array) solder joints. The AXI system uses X-rays to penetrate the circuit board, generating images of the internal structure to check solder joint quality and internal defects.

Advantages

The primary advantage of AXI technology is its ability to detect internal solder joint defects, which may affect the long-term reliability of the circuit board. By using AXI, PCBA manufacturers can ensure that solder quality meets standards, thereby improving product yield and reliability.

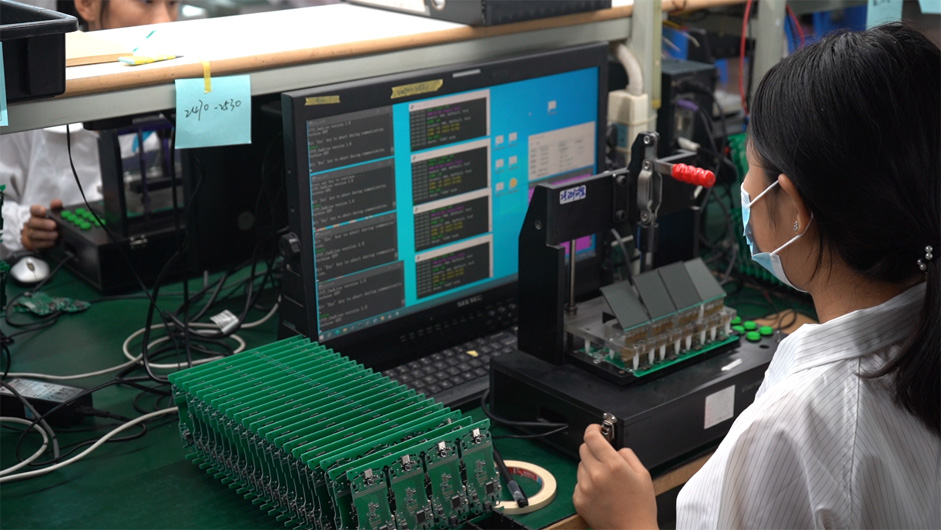

3. Functional Testing

Function and Application

Functional testing is a comprehensive performance test of the alarm system PCBA to verify that it operates according to design specifications. Testing typically includes electrical testing, signal testing, and functional verification. Functional testing can be performed at various stages of the production line, including board-level testing and full-unit testing.

Advantages

Functional testing allows manufacturers to verify the performance of the PCBA in real-world applications, ensuring that all functions function properly. This testing can identify design flaws or production issues, ensuring that the product's functionality and performance meet customer requirements before shipment. Comprehensive functional testing helps significantly improve product yields.

4. Environmental Testing

Functions and Applications

Environmental testing simulates the operating conditions of alarm system PCBAs under various environmental conditions, including temperature, humidity, and vibration. These tests assess the stability and reliability of PCBAs under these conditions, ensuring their proper function in real-world applications.

Benefits

Environmental testing helps identify potential product issues in extreme environments, thereby improving product durability and reliability. By conducting environmental testing during production, factories can ensure product yields under various operating conditions, reducing returns and repair costs.

5. Statistical Process Control (SPC)

Functions and Applications

Statistical Process Control (SPC) is a technology that uses statistical methods to monitor and analyze production processes. SPC monitors production data in real time to identify and control variations in the production process, ensuring consistent product quality.

Benefits

The advantage of SPC technology lies in its ability to promptly detect and correct abnormalities in the production process. This approach not only improves product yields but also optimizes production processes, reducing scrap and rework. The application of SPC helps maintain stability and consistency in the production process, thereby improving overall product quality.

Conclusion

In alarm system PCBA manufacturing, advanced testing technologies are crucial to ensuring product quality. Technologies such as automated optical inspection (AOI), X-ray inspection (AXI), functional testing, environmental testing, and statistical process control (SPC) enable comprehensive PCBA inspection and verification from various perspectives. These advanced testing technologies enable PCBA factories to promptly identify and resolve production process issues, thereby improving product quality and ensuring that product quality meets customer requirements. These technologies not only improve production efficiency but also enhance factories' market competitiveness.

Send Inquiry

-

Delivery Service

-

Payment Options