- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can we ensure that Router PCBA factories' multi-layer board processing capabilities meet complex demands?

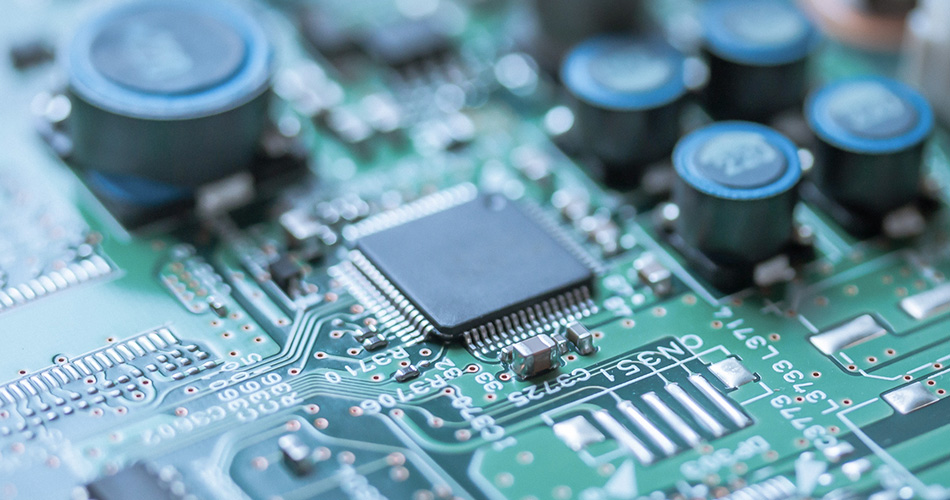

In the field of router PCBA (Printed Circuit Board Assembly) processing, multi-layer board processing is a technically complex and demanding task. Multi-layer boards refer to printed circuit boards with multiple layers, and their processing involves many complex technical and process requirements. Ensuring that PCBA factories can meet these complex demands is crucial for providing high-quality electronic products. This article will explore how to ensure that PCBA factories' multi-layer board processing capabilities meet these complex demands.

1. Technical Capabilities and Equipment Level

Advanced Equipment

Multi-layer board processing requires high-precision and high-reliability equipment. Ensuring that PCBA factories have advanced processing equipment, such as high-precision photolithography machines, laser drilling machines, and automated placement machines, can significantly improve multi-layer board processing quality. These machines can handle more complex circuit designs, ensuring precise circuit layout and reliable connections.

Technician Professional Competence

Technician skills and experience are crucial to the success of multi-layer board processing. Factories should ensure that their technicians have the expertise and skills to handle complex multi-layer board designs. Regular training and technical updates should be used to enhance technician capabilities to meet evolving technical requirements and challenges.

2. Process Control

Strict Process Specifications

Multilayer PCB fabrication involves multiple steps, including lamination, drilling, copper plating, etching, and copper overlay. Each step requires strict process control to ensure the quality of the final product. Factories should establish detailed process specifications and operating standards, and implement rigorous process monitoring and quality control to ensure that each step meets requirements.

High-Standard Quality Inspection

During the multilayer PCB fabrication process, quality inspection is a crucial step in ensuring that the product meets complex requirements. Factories should be equipped with advanced inspection equipment, such as automated optical inspection (AOI) and X-ray inspection systems, to conduct a comprehensive quality inspection of each multilayer PCB. These inspection devices can detect potential defects such as shorts, opens, and solder joints, ensuring high product quality.

3. Close Coordination between Design and Production

Collaboration during the Design Phase

The complex design of multilayer PCBs requires close collaboration between designers and production teams. During the design phase, designers should consider the limitations and requirements of the production process and communicate with the production team to ensure that the design can be smoothly translated into the actual product. Factories should work closely with customers, providing technical support and advice to optimize the design and mitigate production issues.

Flexible Response During Production

During the production process, factories need to be able to flexibly respond to design changes and complex requirements. As production progresses, design modifications or process adjustments may be needed. Factories should be able to quickly adapt to these changes and promptly adjust production processes and procedures to ensure that the final product meets the customer's complex needs.

4. Management and Continuous Improvement

Effective Production Management

Effective production management ensures the smooth progress of multilayer board processing. Factories should establish a comprehensive production management system, including production planning, resource allocation, and progress tracking. Through rational production scheduling and resource optimization, production efficiency can be improved, bottlenecks can be reduced, and complex requirements can be met.

Continuous Improvement and Innovation

Multilayer board processing technology and processes are constantly evolving, and factories should continuously innovate and improve their processes. By introducing new technologies, optimizing production processes, and upgrading equipment, factories can improve processing capabilities and product quality to meet evolving market demands.

Conclusion

In router PCBA processing, the complex demands of multilayer board processing require factories to have advanced equipment, professional technicians, strict process control, and high-standard quality inspections. Through close coordination between design and production, effective production management and continuous improvement, the factory can ensure that its multi-layer board processing capabilities can meet the complex market demands. This not only improves production efficiency, but also enhances product quality and strengthens market competitiveness.

Send Inquiry

-

Delivery Service

-

Payment Options