- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Quality Control and Improvement in PCBA Factories: From Problem Discovery to Resolution

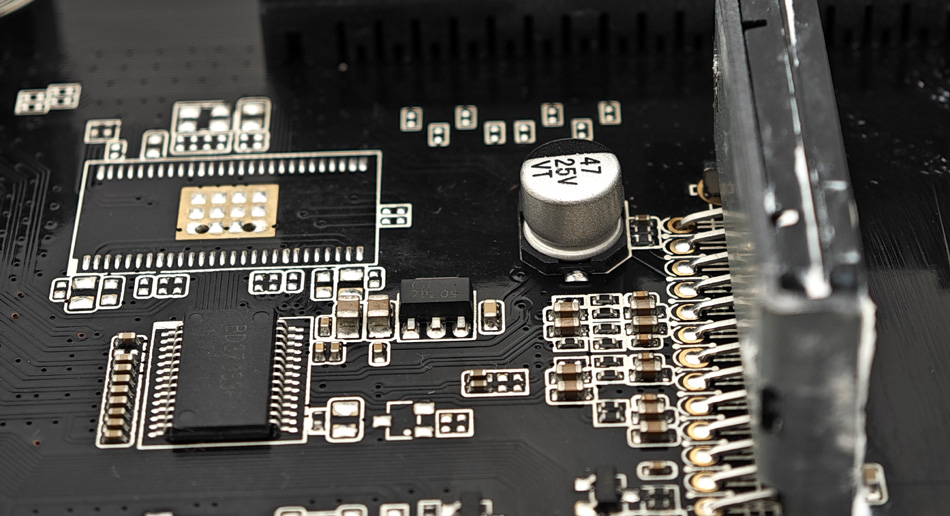

In the fiercely competitive electronics manufacturing industry, the quality of PCBA (Printed Circuit Board Assembly) processing directly impacts product performance and reliability. Therefore, establishing an effective quality control system to ensure problem detection and resolution is a must for every PCBA factory. This article will explore how PCBA factories can implement comprehensive quality control and improvement, from problem discovery to resolution.

1. The Importance of Quality Control

Quality control not only verifies product compliance but also serves as a crucial step in ensuring a stable and efficient production process. Effective quality control can:

Improve product reliability: Through strict quality standards, every PCBA product undergoes meticulous inspection before shipment, reducing failure rates.

Reducing production costs: Early detection and resolution of problems effectively reduces scrap and rework costs.

Enhancing customer trust: Consistent quality increases customer willingness and trust in the factory's products, enhancing market competitiveness.

2. Problem Discovery Mechanism

Problem discovery is the first step in quality control. PCBA factories should employ a variety of methods to ensure timely identification of potential quality issues.

2.1 Automated Inspection

Utilizing advanced technologies such as automated optical inspection (AOI) and X-ray inspection, factories can monitor soldering quality and component placement in real time during the production process, quickly identifying defects. The introduction of these technologies significantly improves inspection accuracy and efficiency.

2.2 Data Analysis

By collecting various data from the production process, factories can analyze common defect types and their frequency. Using statistical process control (SPC) methods, production deviations can be promptly identified and preventive measures implemented.

2.3 Employee Feedback

Factories should encourage employee participation in quality management and establish a problem feedback mechanism. Employees have the most intimate knowledge of the production process through their daily work, and timely feedback facilitates swift action.

3. Problem Solving Process

Once a problem is discovered, timely and effective resolution is key to quality control. PCBA factories should establish a clear problem-solving process.

3.1 Problem Analysis

Once a defect is discovered, the factory should conduct a root cause analysis (RCA) to identify the underlying source of the problem. Comprehensive problem analysis should be ensured through data review, on-site investigations, and team discussions.

3.2 Developing Solutions

Based on the analysis results, develop appropriate solutions. These solutions may include modifying production processes, optimizing equipment parameters, or enhancing employee training. All solutions must be reviewed to ensure their feasibility.

3.3 Implementation and Verification

After implementing the developed solutions, the factory should conduct follow-up verification to ensure that the issues have been resolved. The effectiveness of the improvement measures should be confirmed through retesting and data analysis.

4. Continuous Improvement

Quality control is not a one-time effort but an ongoing process. PCBA factories should regularly evaluate their quality control systems and implement continuous improvements.

4.1 Internal Audits

Conduct regular internal audits to assess the effectiveness of the quality management system. Through audits, potential issues can be identified and timely adjustments can be made.

4.2 Training and Enhancement

Provide ongoing training and skills development for employees to enhance their awareness and ability in quality control. Employee quality directly impacts production quality, and training is an essential component.

4.3 Customer Feedback

Evaluate customer feedback and make timely adjustments to products and services. Changing customer needs can also influence the optimization and improvement of production processes.

Conclusion

Establishing an effective quality control system is crucial in PCBA manufacturing. By implementing a systematic process from problem identification to resolution, factories can not only improve product quality but also enhance their market competitiveness. Continuous improvement and optimization will ensure that factories remain ahead of the curve and meet the challenges of the market.

Send Inquiry

-

Delivery Service

-

Payment Options