- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Evaluate a PCBA Factory's Capabilities in High-Density PCB Processing?

2025-11-06

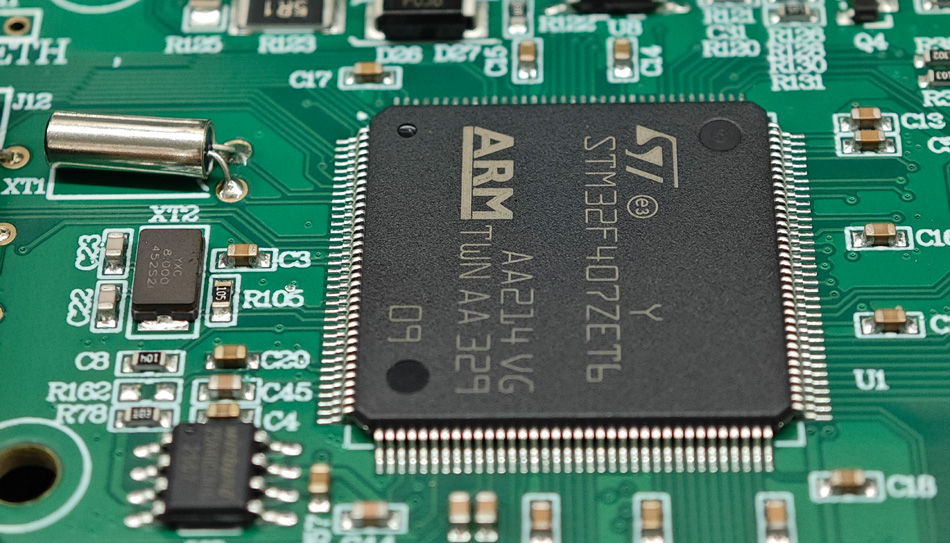

In the manufacturing of modern electronic products, demand for high-density printed circuit boards (HDI PCBs) is growing. These PCBs are widely used due to their miniaturization and diverse functionality. However, processing HDI PCBs places higher demands on the capabilities of PCBA (Printed Circuit Board Assembly) factories. This article will explore how to evaluate a PCBA factory's capabilities in high-density PCB processing.

1. Evaluating a Factory's Equipment and Technology

Advanced Production Equipment

First, assessing whether a PCBA factory possesses advanced production equipment is crucial. High-density PCB processing requires the use of high-precision placement machines, reflow soldering machines, and laser cutting equipment. The factory should be equipped with equipment capable of meeting the demands of high-density PCBs to ensure processing accuracy and efficiency.

Soldering and Mounting Technology

High-density PCBs are densely packed with components, requiring extremely high soldering and mounting techniques. Evaluating a factory's application of advanced soldering technologies such as lead-free soldering and laser soldering, as well as its ability to mount micro-components, are important indicators of its processing capabilities.

2. Quality Management System

ISO Certification and Standards

A mature quality management system is the foundation for evaluating PCBA factory capabilities. Checking whether a factory has obtained international quality management certifications such as ISO 9001 can provide insights into its quality control and management capabilities. A well-established quality system will help the factory maintain consistent product quality during high-density PCB processing.

Quality Inspection Process

Equally important is evaluating the factory's quality inspection process. The factory should have a comprehensive inspection process, including in-line inspection, AOI (automated optical inspection), and X-ray inspection, to ensure that problems are detected and corrected promptly during production. A sound quality control process can effectively reduce rework and scrap rates.

3. Personnel Training and Skills

Professional Technical Staff

High-density PCB processing requires professional technical staff. Assess the factory's staff skills and training system to determine whether they receive regular training to maintain technical skills and enhance their skills. Qualified technical staff are key to ensuring high-quality production.

Teamwork and Communication

In high-density PCB processing, collaboration and communication between departments are crucial. Evaluating a factory's project management and teamwork capabilities can help you gauge its ability to handle complex projects.

4. Practical Production Experience and Case Studies

Project Experience

Assessing a PCBA factory's practical experience in high-density PCB processing is also crucial. Reviewing the factory's past project cases, especially those involving similar products, can help you assess its capabilities and experience in handling high-density PCBs.

Customer Feedback and Word-of-Mouth

By understanding customer feedback and reviews of a factory, you can gain more insightful insights. Positive customer feedback and a strong reputation are crucial indicators for evaluating a factory's capabilities in high-density PCB processing.

5. Future Development Potential

Technological Innovation

Finally, evaluating a PCBA factory's technological innovation capabilities is crucial. With the rapid development of the electronics industry, new technologies are constantly emerging. Whether a factory can proactively adapt to industry trends and invest in new technologies, equipment, and processes reflects its future development potential.

Flexibility

A factory's ability to quickly adjust its production lines and processes in response to changing market demands will impact its competitiveness in high-density PCB processing. Factories with strong adaptability are more likely to stand out in this complex and volatile market.

Conclusion

Evaluating a PCBA factory's capabilities for high-density PCB processing requires comprehensive consideration of multiple factors, including equipment technology, quality management, personnel skills, practical experience, and future development potential. This comprehensive assessment can help clients select the right partner to ensure optimal quality and efficiency in high-density PCB processing. As electronic products become increasingly complex, finding a PCBA factory with strong capabilities is crucial to business success.

-

Delivery Service

-

Payment Options