- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Difficulties in Multi-Layer PCB Manufacturing and Strategies for PCBA Manufacturers

2025-11-07

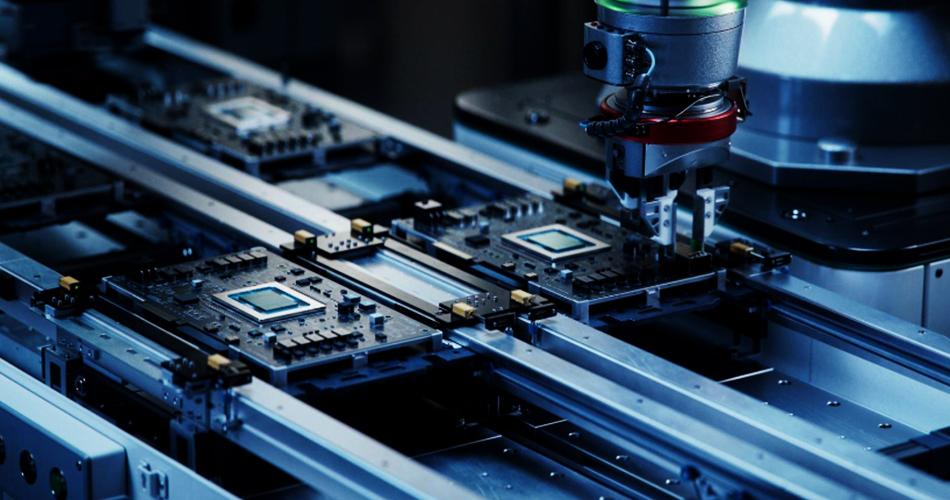

Multi-layer PCBs (Printed Circuit Boards) are widely used in modern electronic devices due to their high-density layout and functional integration. However, the manufacturing process is complex and presents numerous challenges. This article will explore the main difficulties in multi-layer PCB manufacturing and the strategies for PCBA manufacturers to address them.

1. Main Difficulties in Multi-Layer PCB Manufacturing

Design Complexity

Multi-layer PCB design typically involves multiple circuit layers and complex signal paths, which further complicates the design process. The design process must consider issues such as signal integrity, power distribution, and thermal management between layers. Any design errors can lead to degraded board performance.

High Manufacturing Process Requirements

The manufacturing process for multi-layer PCBs requires extremely high process requirements, including lamination, drilling, copper plating, and soldering. Each step requires strict control to ensure the overall quality and reliability of the board.

Thermal Management Issues

With the increasing power density of electronic devices, thermal management issues have become increasingly prominent. Multi-layer PCBs can generate significant heat during operation, making effective heat dissipation a critical consideration during design and manufacturing.

2. PCBA Factory Response Strategies

2.1 Strengthening Design Review and Collaboration

During the design phase of multi-layer PCBs, PCBA factories should collaborate closely with customers and conduct thorough design reviews. This includes:

Early Communication

Early communication with customers ensures accurate communication of design requirements and reduces the risks associated with design changes.

Design Verification

Using EDA (Electronic Design Automation) tools to verify the design and identify potential issues, thereby reducing risks in subsequent processing.

2.2 Adopting Advanced Manufacturing Technologies

To overcome the technical difficulties in multi-layer PCB processing, PCBA factories should adopt advanced manufacturing technologies:

Precision Lamination Technology

Using high-precision lamination equipment and materials ensures interlayer bonding quality and signal integrity in multi-layer PCBs. Modern lamination technology provides better thickness control and higher reliability.

High-Speed Drilling and Copper Plating Technology

Using efficient drilling and copper plating equipment ensures accurate drill hole placement and uniform copper plating to meet the process requirements of multi-layer PCBs.

2.3 Strengthening Quality Control Processes

Quality control is crucial in multi-layer PCB processing. PCBA factories should establish a comprehensive quality management system:

Online Monitoring

Implement online monitoring during the production process to monitor key process parameters in real time, promptly identify and correct problems, and ensure product quality.

Specialized Inspection Technology for Multilayer Boards

Advanced inspection technologies such as AOI (Automated Optical Inspection) and X-ray inspection are used to comprehensively inspect the characteristics of multilayer PCBs, ensuring that each circuit board meets quality standards.

3. Thermal Management Solutions

In multilayer PCB processing, thermal management is an essential issue. PCBA factories can improve thermal management through the following measures:

Heat Dissipation Design Optimization

During the PCB design phase, rationally design heat dissipation channels and heat source distribution to reduce heat accumulation and improve heat dissipation efficiency.

Use High Thermal Conductivity Materials

Select materials and heat sinks with high thermal conductivity to improve heat transfer, help reduce PCB surface temperatures, and extend product life.

Conclusion

Multilayer PCB processing faces challenges such as design complexity, high manufacturing requirements, and thermal management. PCBA factories can address these challenges by strengthening design reviews and collaboration, adopting advanced manufacturing technologies, and strengthening quality control processes. At the same time, paying attention to thermal management issues, reasonable design and material selection will further improve the performance and reliability of multi-layer PCBs. In the fierce market competition, PCBA factories need to continuously innovate and optimize processes to meet customers' growing demand for multi-layer PCBs.

-

Delivery Service

-

Payment Options