- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

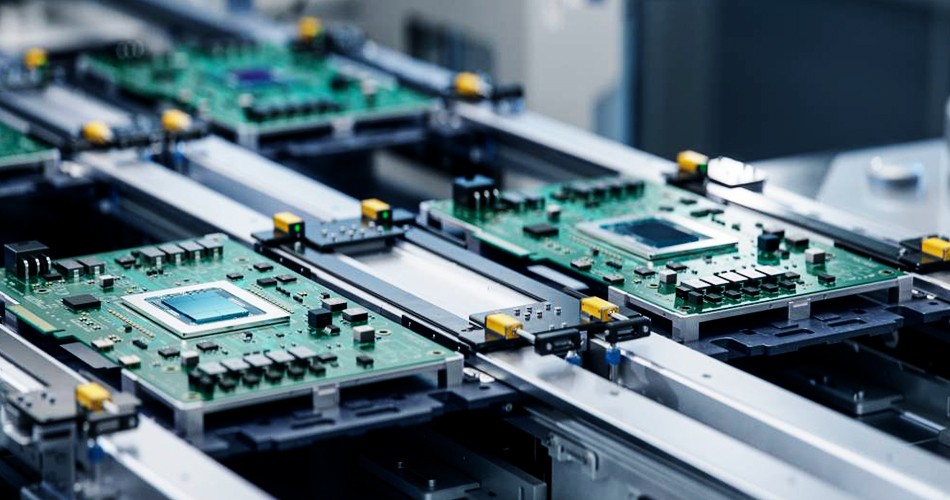

Exploring the Latest Technological Innovations and Applications in PCBA Factories

2025-11-05

With the rapid development of the electronics industry, PCBA (Printed Circuit Board Assembly) processing technology is constantly innovating and upgrading. The application of new technologies not only improves production efficiency but also enhances product quality, driving progress across the industry. This article will explore some of the latest technological innovations in PCBA factories and their practical applications.

1. Automated Production Lines

Automated production lines have become key to improving efficiency and consistency in PCBA processing. By introducing robots and automated equipment, factories can automate the entire process, from component placement to soldering and inspection.

Improving Production Efficiency

Automated production lines can significantly shorten production cycles, reduce manual intervention, and improve production efficiency. This is particularly important for meeting market demand for high-volume, high-quality products.

Reducing Labor Costs

By replacing traditional manual operations with automated equipment, factories can significantly reduce labor costs and minimize quality issues caused by human error.

2. Advanced Soldering Technologies

Soldering is one of the most critical processes in PCBA processing. In recent years, many advanced soldering technologies have been introduced to improve soldering quality and reliability.

Laser Soldering

Laser soldering technology, with its high precision and controllability, is gradually replacing traditional soldering methods. Laser soldering enables fast soldering and reduces damage to heat-sensitive components, thereby improving soldering quality.

Lead-Free Soldering

With increasingly stringent environmental regulations, lead-free soldering has become a key trend in PCBA processing. Lead-free solders demonstrate excellent performance during the soldering process, ensuring the environmental friendliness and reliability of the product.

3. Data-Driven Smart Manufacturing

Smart manufacturing is the future direction of the manufacturing industry, and the PCBA processing sector is no exception. Through the Internet of Things (IoT) and big data analytics, factories can monitor the production process in real time and achieve intelligent management.

Real-Time Data Monitoring

By installing sensors and monitoring equipment, PCBA factories can obtain real-time production data. This data can be used to analyze production efficiency, equipment status, and quality indicators, enabling dynamic adjustments and optimization.

Predictive Maintenance

Based on data analysis, factories can implement predictive maintenance. By monitoring equipment operating status, potential failures can be identified in advance, reducing downtime and ensuring continuous and stable production.

4. Additive Manufacturing (3D Printing)

Additive manufacturing technology is increasingly being used in PCBA manufacturing, especially in prototyping and low-volume production.

Rapid Prototyping

Using 3D printing, engineers can quickly create prototypes of circuit boards. This rapid iteration significantly shortens design and testing cycles, accelerating time to market.

Customized Production

Additive manufacturing enables personalized and low-volume production to meet the specific needs of diverse customers. This flexibility allows PCBA factories to better adapt to market changes.

Conclusion

With the continuous advancement of technology, PCBA factories have demonstrated tremendous potential for technological innovation. The application of new technologies such as automated production lines, advanced soldering techniques, intelligent manufacturing, and additive manufacturing has not only improved production efficiency and product quality, but also promoted the sustainable development of the entire industry. Going forward, PCBA factories must continue to focus on technological innovation and actively explore new applications to meet the ever-changing and challenging market. In this rapidly evolving industry, technological innovation will be key to maintaining competitiveness.

-

Delivery Service

-

Payment Options