- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can PCBA factories improve their product competitiveness through advanced SMT processes?

2025-11-03

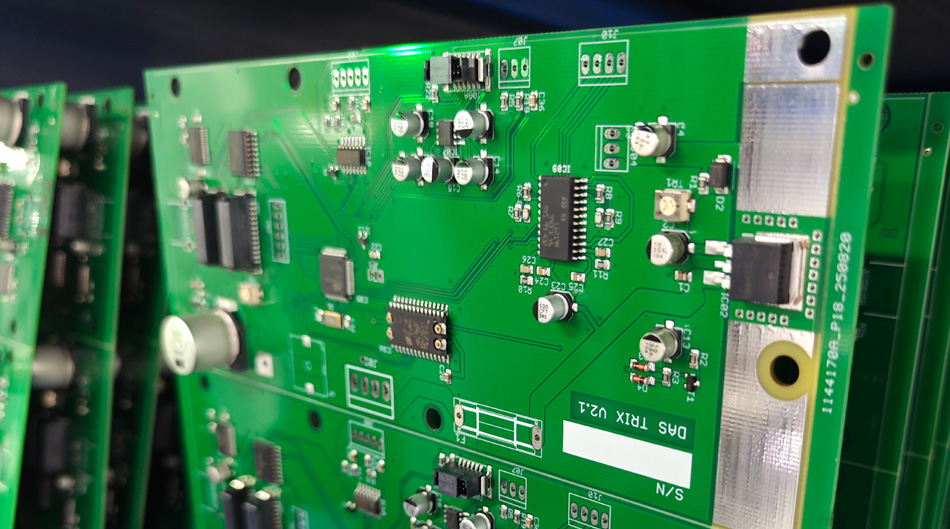

In today's highly competitive electronics market, PCBA (Printed Circuit Board Assembly) factories face the dual challenges of improving production efficiency and product quality. Surface mount technology (SMT), as an advanced PCB processing technique, has become a key factor in enhancing product competitiveness. This article will explore how PCBA factories can enhance product competitiveness through advanced SMT processes.

1. Advantages of SMT Processes

High-Density Component Placement

SMT allows for more components to be placed in a smaller space, making it suitable for the production of high-density circuit boards. This high-density layout meets the miniaturization and lightweight requirements of modern electronic products, thereby enhancing product competitiveness.

Improving Production Efficiency

Compared to traditional insertion technology, SMT allows for faster production speeds. The use of automated equipment not only improves placement efficiency but also reduces the need for manual intervention, thereby lowering production costs.

2. Introducing Advanced Equipment

High-Speed Placement Machines

PCBA factories can improve their SMT production capacity by introducing high-speed placement machines. These devices are equipped with high-precision laser alignment systems, enabling fast and accurate component placement, improving production efficiency and product quality.

Automated Vision Inspection System

To ensure placement quality, PCBA factories should be equipped with automated vision inspection systems. These systems monitor component position and status in real time during the placement process, promptly detecting and correcting errors and reducing defect rates.

3. Process Optimization

Fine Adjustment of Process Parameters

In the SMT process, precise control of various process parameters (such as solder paste printing and reflow soldering) is crucial. PCBA factories can optimize process parameters through experimentation and data analysis to ensure that every production step meets the highest standards.

Process Standardization

Establishing standardized production processes can reduce production variation and improve product consistency. PCBA factories should develop detailed work instructions and provide systematic employee training to ensure that every employee is proficient in standard operating procedures.

4. Strengthening Quality Management

Comprehensive Quality Control

Establishing a comprehensive quality management system is crucial during the PCBA process. Factories should implement quality control at every stage of production, from incoming materials to the production process to finished product inspection, ensuring that quality standards are met at every step.

Adopting Advanced Inspection Technologies

To improve product quality, PCBA factories can employ a variety of inspection technologies, such as automated optical inspection (AOI) and X-ray inspection. These advanced technologies can promptly detect production issues and ensure the reliability of the final product.

5. Continuous Technological Innovation

Regular Technical Training

PCBA factories should provide regular technical training to their employees to help them master the latest SMT processes and equipment operating skills. By continuously improving their employees' technical skills, factories can better respond to market changes and customer needs.

Investing in R&D

In the SMT process, continuous technological innovation is a key means of enhancing product competitiveness. PCBA factories should increase their investment in R&D and explore new materials, processes, and equipment to maintain their competitive advantage in the industry.

Conclusion

Through advanced SMT processes, PCBA factories can enhance product competitiveness through high-density component placement, improved production efficiency, optimized process flows, strengthened quality management, and continuous technological innovation. In the rapidly changing electronics market, mastering and applying advanced SMT technology will be an important guarantee for PCBA factories to maintain their competitiveness. Looking to the future, factories should continue to pay attention to technological development and market demand, and promote continuous innovation in production methods to meet customer expectations and industry challenges.

-

Delivery Service

-

Payment Options