- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Accelerate Projects Through electronic air pump PCBA Factory Efficiency Improvements?

2025-12-05

In the electronic air pump PCBA (Printed Circuit Board Assembly) manufacturing industry, project acceleration is crucial for meeting market demands and shortening time-to-market. Choosing an efficient PCBA factory can significantly improve overall project efficiency, leading to faster project progress. This article explores key strategies for accelerating projects through PCBA factory efficiency improvements and analyzes how these strategies can help companies achieve their goals faster.

1. Optimize Production Processes

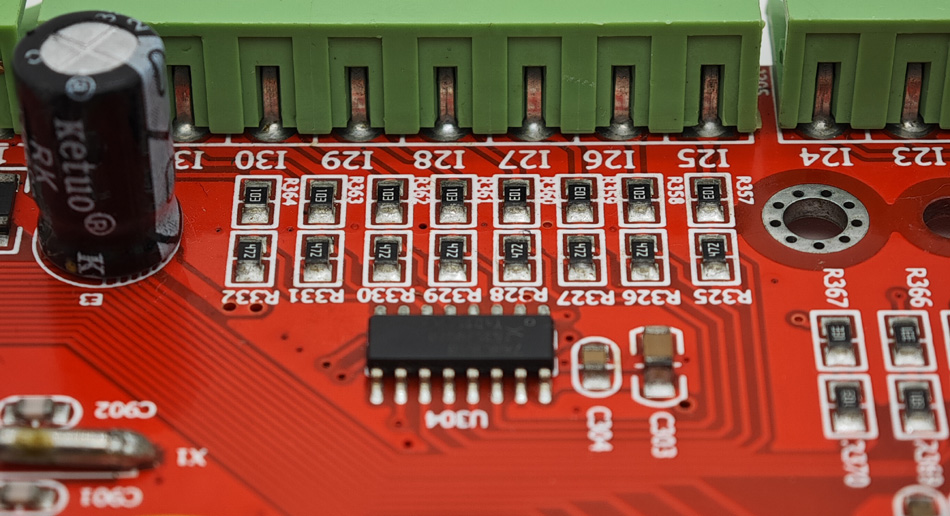

Improving efficiency through production process optimization is a key step in accelerating projects for electronic air pump PCBA factories. Factories can optimize production processes through refined production line management, reducing unnecessary operational steps, and increasing automation. For example, adopting advanced SMT (Surface Mount Technology) equipment and automated soldering technology can significantly improve production speed and accuracy. Furthermore, by implementing lean manufacturing methods, factories can reduce waste in production and improve overall production efficiency. These optimizations can shorten production cycles and accelerate project progress.

2. Implement Efficient Supply Chain Management

Efficient supply chain management is crucial for accelerating projects in electronic air pump PCBA factories. Factories need to establish strong partnerships with suppliers to ensure the timely supply of raw materials and components. By establishing a reliable supply chain network and optimizing procurement processes, factories can reduce raw material procurement time and costs. Furthermore, factories can implement inventory management systems to monitor inventory levels in real time, avoiding production delays caused by material shortages. Efficient supply chain management not only improves production efficiency but also ensures projects proceed on schedule.

3. Enhancing R&D and Design Capabilities

The R&D and design capabilities of a electronic air pump PCBA factory directly impact overall project efficiency. By enhancing R&D capabilities, factories can provide more efficient design services, shortening the product cycle from design to production. For example, factories can utilize advanced CAD (Computer-Aided Design) software for design optimization and identify potential problems early through simulation and testing. This early intervention in design reduces later modifications and adjustments, ensuring smooth project progress. Moreover, by continuously updating and introducing new technologies, factories can provide more innovative solutions during the design phase, further improving project execution efficiency.

4. Implementing Real-Time Monitoring and Data Analysis

Real-time monitoring and data analysis are crucial tools for improving electronic air pump PCBA factory efficiency. Factories can utilize modern production monitoring systems to track production progress, quality indicators, and equipment status in real time. Through data analysis, factories can identify bottlenecks and potential problems in production and take timely corrective actions to adjust. This real-time feedback and adjustment capability improves production efficiency, reduces production downtime, and thus accelerates project progress. For example, by analyzing production data, factories can optimize production scheduling, reduce equipment idle time, and ensure the efficient operation of production lines.

5. Strengthen Team Training and Management

Improving the efficiency of electronic air pump PCBA factories also requires strengthening team training and management. Factories should regularly provide skills training to employees to ensure they master the latest production technologies and operating procedures. By improving employee professional skills and work efficiency, human error and production defects can be reduced, thereby improving overall production efficiency. In addition, factories should strengthen team collaboration and management, optimize workflows, and ensure coordination between departments. Good team management can improve production line operating efficiency and further accelerate project progress.

Conclusion

By optimizing production processes, implementing efficient supply chain management, improving R&D and design capabilities, real-time monitoring and data analysis, and strengthening team training and management, electronic air pump PCBA factories can significantly improve the overall efficiency of projects. These strategies not only improve production speed and quality but also ensure that projects can proceed on schedule. For businesses, choosing an efficient electronic air pump PCBA factory and implementing these strategies will help accelerate projects and enable rapid market response, thus helping them stand out in a highly competitive market environment.

-

Delivery Service

-

Payment Options