- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Choose a Suitable Automobile PCBA Factory Globally?

2025-12-04

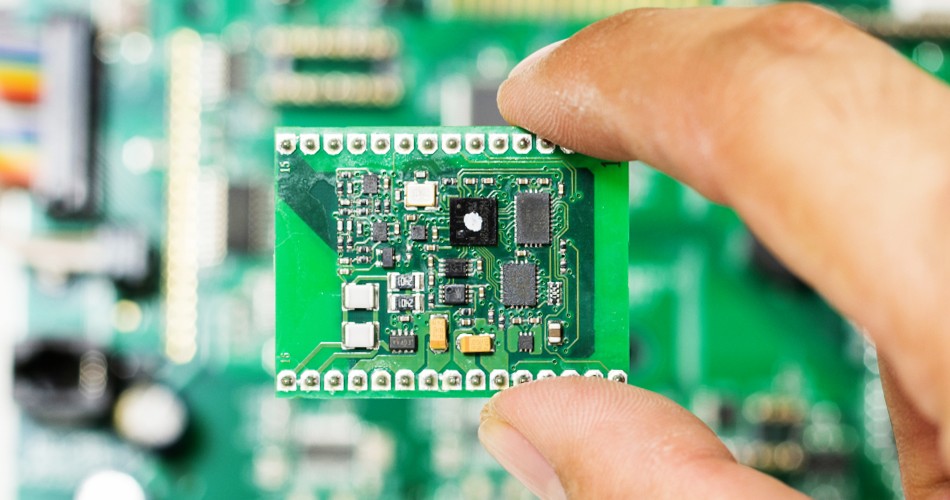

In a globalized market environment, selecting a suitable Automobile PCBA (Printed Circuit Board Assembly) processing factory is crucial for ensuring project success and efficient production. With technological advancements and market changes, businesses face numerous choices. This article explores the key factors for selecting a suitable PCBA factory globally, helping companies make informed decisions.

1. Factory's Technical Capabilities

The primary consideration when choosing a automobile PCBA factory is its technical capabilities. Different automobile PCBA factories possess different technical expertise and equipment configurations. Companies should assess whether the factory possesses the necessary production technologies, including SMT (Surface Mount Technology), BGA (Ball Grid Array), and FPC (Flexible Printed Circuit Board). The factory's ability to handle complex design requirements, such as multilayer boards and high-density interconnect (HDI) boards, should also be considered. Technical capabilities directly impact production quality and product reliability; therefore, when selecting a factory, it's essential to ensure its technical level meets project requirements.

2. Production Capacity and Delivery Time

Production capacity and delivery time are critical factors when selecting a automobile PCBA factory. Companies need to confirm whether the factory's production capacity matches the project's scale and time requirements. Production capacity includes a factory's output, the number of production lines, and the modernization level of its equipment. Regarding delivery time, companies should understand the factory's production cycle and delivery commitments to ensure it can complete production tasks within the expected timeframe. Furthermore, the factory's flexibility and ability to handle urgent orders should be considered to address potential production fluctuations and changes in market demand.

3. Quality Control System

Quality control is a crucial aspect of ensuring automobile PCBA processing quality. When selecting a factory, companies should thoroughly understand its quality control system, including its implemented standards, testing procedures, and certifications. Common quality certifications such as ISO 9001, IATF 16949 (automotive industry), and ISO 14001 (environmental management) reflect a factory's quality management level. Companies should also examine the factory's testing capabilities, such as functional testing, environmental testing, and reliability testing, to ensure that products meet quality requirements during production and can withstand various usage conditions.

4. Cost and Cost-Effectiveness

Cost is a critical factor to consider when selecting a automobile PCBA factory. Companies need to compare quotations from different factories and evaluate their cost-effectiveness. While cost is key, companies should not only focus on the lowest price.

5. Service and Support

Good customer service and technical support are crucial for the smooth progress of a project. Companies should choose PCBA factories that offer comprehensive services, including engineering support, technical consulting, and after-sales service. The level of service provided by the factory can influence product development and production processes. For example, rapid technical support can help resolve design and production issues, improving overall project efficiency. Understanding the factory's customer service processes, support team expertise, and service history helps ensure necessary support and assistance are obtained during the collaboration.

6. Geographic Location and Supply Chain Management

The geographical location of a factory affects supply chain management and logistics costs. Choosing a strategically located factory can shorten transportation time and reduce logistics costs. Furthermore, geographical location affects the ease of communication and coordination with the factory. When selecting factories globally, companies should consider the compatibility of the factory's location with their own supply chain network to optimize overall supply chain efficiency.

Conclusion

Selecting a suitable automobile PCBA factory globally requires comprehensive consideration of factors such as the factory's technological capabilities, production capacity and delivery time, quality control system, cost and performance, service and support, and geographical location. By systematically evaluating these key factors, companies can select the factory that best meets their needs, thereby ensuring successful project implementation and efficient production. Choosing the right PCBA factory not only helps improve product quality and production efficiency but also optimizes supply chain management and enhances the company's market competitiveness.

-

Delivery Service

-

Payment Options