- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

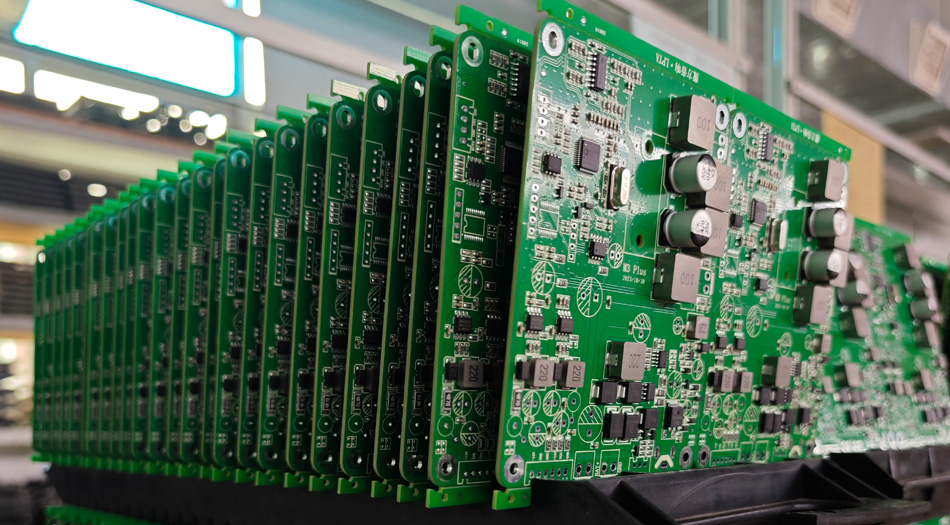

Medical Equipment PCBA Factory Capacity Management: Strategies for Coping with Order Fluctuations

2025-12-01

In the Medical Equipment PCBA (Printed Circuit Board Assembly) manufacturing industry, capacity management is crucial for ensuring production efficiency and customer satisfaction. Facing fluctuations in market demand, effectively responding to order changes and maintaining the flexibility and stability of the production line is a problem every PCBA factory must solve. This article will explore several strategies for coping with order fluctuations to help PCBA factories optimize capacity management and improve their ability to respond to changes.

1. Implementing Flexible Production Scheduling

Flexible production scheduling is one of the important strategies for coping with order fluctuations. Factories can achieve flexible scheduling through the following methods:

Dynamic Scheduling System: Introducing an advanced production scheduling system allows for real-time adjustments to production plans and optimization of production resource allocation. Dynamic scheduling systems can automatically adjust the priority and sequence of production tasks based on the urgency of orders and production capacity, thereby improving the responsiveness of the production line.

Production Plan Adjustment: Regularly review and adjust production plans to respond to changes in market demand. By forecasting market demand and analyzing order data, production plans can be adjusted in a timely manner to ensure optimal allocation of production resources.

1. Short-Term Production Capacity Adjustment: During periods of surging demand, short-term production capacity can be increased by adding production shifts or overtime. Flexible adjustments to production shifts effectively address peak order periods and ensure on-time delivery.

2. Optimized Inventory Management

Effective inventory management helps Medical Equipment PCBA factories cope with order fluctuations and reduce the risk of production delays:

Safety Stock Setting: Setting reasonable safety stock levels to cope with sudden changes in order volume. Safety stock provides a buffer when demand increases, preventing production delays due to insufficient raw materials or components.

Inventory Turnover Improvement: Improving inventory turnover by optimizing procurement and production plans. Reducing excess inventory and inventory backlog, increasing the liquidity of raw materials and finished products, thereby reducing inventory costs.

Supply Chain Collaboration: Establishing strong partnerships with suppliers ensures timely supply of raw materials and components. Through supply chain collaboration, early warnings and adjustments to inventory levels can be made, reducing production delays caused by supply chain issues.

3. Enhance Production Capacity Forecasting

Accurate production capacity forecasting helps Medical Equipment PCBA factories maintain stability amidst order fluctuations:

Data-Driven Forecasting: Utilizing historical order data and market trends to conduct accurate production capacity forecasts. Data analysis helps factories predict future demand changes and prepare production resources in advance.

Flexible Production Line Configuration: Adjusting production line configuration and equipment arrangements based on forecast results. Flexible production line configuration allows for rapid adjustments to production processes and equipment to adapt to changing order demands.

Forecast Model Optimization: Continuously optimizing forecast models to improve accuracy. By continuously adjusting and refining forecast models, forecast errors are reduced, ensuring the scientific and rational nature of production plans.

4. Strengthen Employee Training and Management

Employee training and management are also crucial factors in coping with order fluctuations:

Skills Training: Providing skills training to employees improves their adaptability to different production tasks. Training helps employees master multiple production processes, improving the flexibility and responsiveness of the production line.

Multi-Skilled Worker System: Implementing a multi-skilled worker system enables employees to be competent in multiple production positions. A multi-skilled workforce allows for rapid adjustments to staffing during order fluctuations, ensuring the production line operates smoothly.

Incentive Mechanisms: Establishing effective incentive mechanisms enhances employee motivation and productivity. These mechanisms encourage employees to maintain high efficiency during peak order periods, reducing production delays.

5. Introducing Advanced Production Technologies

Advanced production technologies improve capacity management efficiency:

Automated Equipment: Introducing automated production equipment increases the automation level of the production line. Automated equipment reduces manual intervention while maintaining production efficiency, increasing production line flexibility.

Intelligent Manufacturing Systems: Employing intelligent manufacturing systems enables real-time monitoring and data analysis. These systems acquire production data promptly, adjust production parameters in real-time, and optimize the production process.

Flexible Manufacturing Systems: Implementing flexible manufacturing systems allows for rapid adjustments to production line configurations and processes to adapt to different production needs. Flexible manufacturing systems improve the adaptability and responsiveness of the production line.

Conclusion

In the Medical Equipment PCBA manufacturing industry, capacity management is crucial for managing order fluctuations. By implementing flexible production scheduling, optimizing inventory management, enhancing production capacity forecasting, strengthening employee training and management, and introducing advanced production technologies, Medical Equipment PCBA factories can effectively respond to order changes and maintain the stability and efficiency of production lines. The comprehensive application of these strategies not only improves factory production efficiency but also enhances customer satisfaction and achieves sustainable business development.

-

Delivery Service

-

Payment Options