- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

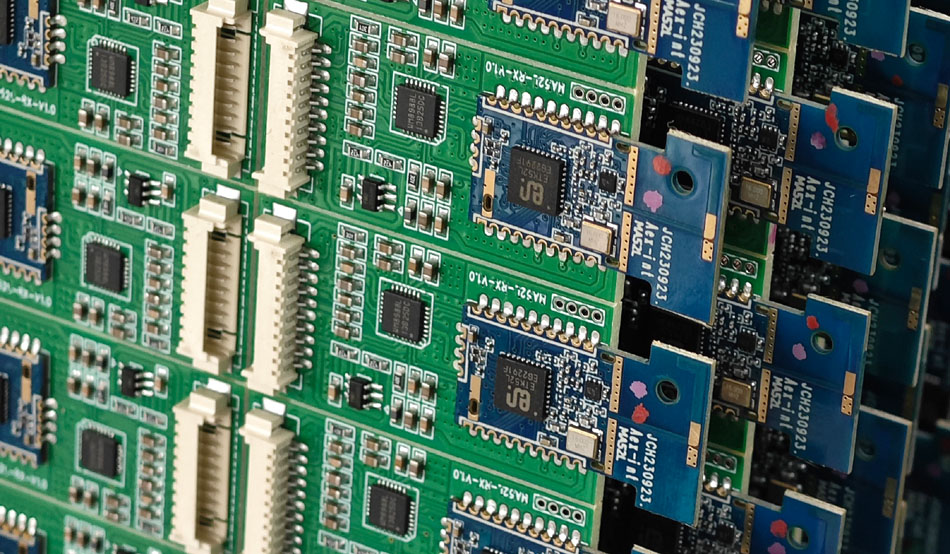

PCBA Factory Production Line Planning: Key Factors Affecting Production Efficiency

2025-11-29

In the PCBA (Printed Circuit Board Assembly) manufacturing field, production line planning is a core factor determining factory production efficiency. A well-designed and planned production line can not only improve production efficiency but also significantly reduce costs, waste, and product quality. This article will explore the key factors affecting the efficiency of PCBA factory production lines and provide suggestions for optimizing production line planning.

1. Production Line Layout

Production line layout directly affects the smoothness and efficiency of the production process. A reasonable layout can reduce material handling distances and production cycles. Here are some key considerations for optimizing the layout:

Flow Layout: Equipment should be arranged rationally according to the production process to ensure a smooth flow from material input to final product output. Adopting a continuous production line layout can reduce intermediate storage time and improve production efficiency.

Modular Design: Through modular layout design, the production line configuration can be flexibly adjusted according to changes in production needs. This design approach not only improves the flexibility of the production line but also facilitates maintenance and upgrades.

Space Optimization: Make rational use of factory space to ensure sufficient operating and maintenance space between production lines. Avoiding an overcrowded layout can reduce the workload of operators and the accident rate.

2. Equipment Selection and Configuration

Equipment is the core of the production line, and its selection and configuration directly impact production efficiency:

Automated Equipment: Introducing automated equipment, such as pick-and-place machines, soldering machines, and testing equipment, can significantly improve production efficiency and consistency. Automated equipment not only increases production speed but also reduces human error.

Equipment Maintenance: Regular maintenance and upkeep of equipment can prevent malfunctions and downtime, improving the stability and reliability of the production line. Establishing an equipment maintenance plan and conducting regular inspections are key to ensuring the efficient operation of the production line.

Compatibility: Selecting equipment that matches the production process ensures compatibility between equipment. Appropriate equipment configuration can avoid bottlenecks in the production process and improve overall production efficiency.

3. Process Flow Optimization

Optimizing the process flow is another important aspect of improving production line efficiency:

Standardized Operations: Developing detailed operating standards and procedures ensures consistency and stability in the production process. Standardized operations not only improve production efficiency but also reduce production variability.

Lean Production: Adopting lean production methods identifies and eliminates waste in the production process. By reducing unnecessary movements and processes, production line efficiency and product quality can be improved.

Real-time Monitoring: Utilizing a production monitoring system to track key indicators in the production process in real time, such as production speed, equipment status, and quality data. Real-time monitoring allows for timely detection and resolution of production problems, optimizing the production process.

4. Personnel Management and Training

Personnel management and training also significantly impact production line efficiency:

Operator Training: Providing systematic training ensures operators master the essentials of equipment operation and production processes. Training improves operator skill levels and reduces human error in production.

Team Collaboration: Strengthening team collaboration ensures smooth coordination between all links in the production line. Good team collaboration improves production efficiency and reduces communication barriers during the production process.

Staffing: Rationally allocating personnel on the production line ensures sufficient operators at each workstation. Too few or too many personnel can negatively impact production line efficiency and operation.

5. Quality Control

Quality control is a crucial step in ensuring product compliance with standards and also affects the overall efficiency of the production line:

Inspection and Testing: Setting appropriate inspection and testing points on the production line allows for timely detection and correction of product defects. Effective quality control measures reduce rework and scrap, improving production efficiency.

Quality Data Analysis: By collecting and analyzing quality data, problems and improvement opportunities in production are identified. Analyzing quality data can help factories optimize production processes, improve product quality, and increase production efficiency.

Conclusion

PCBA factory production line planning involves multiple aspects, from production line layout, equipment selection, and process optimization to personnel management and quality control. Each factor directly impacts production efficiency. Through scientific planning and optimization, production efficiency can be significantly improved, costs reduced, and product quality enhanced. In a highly competitive market environment, careful design and optimization of production lines are crucial to ensuring the success and sustainable development of PCBA processing plants.

-

Delivery Service

-

Payment Options