- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Improve Electric Gardening Tool PCBA Factory Production Efficiency Through Advanced Equipment?

2025-11-28

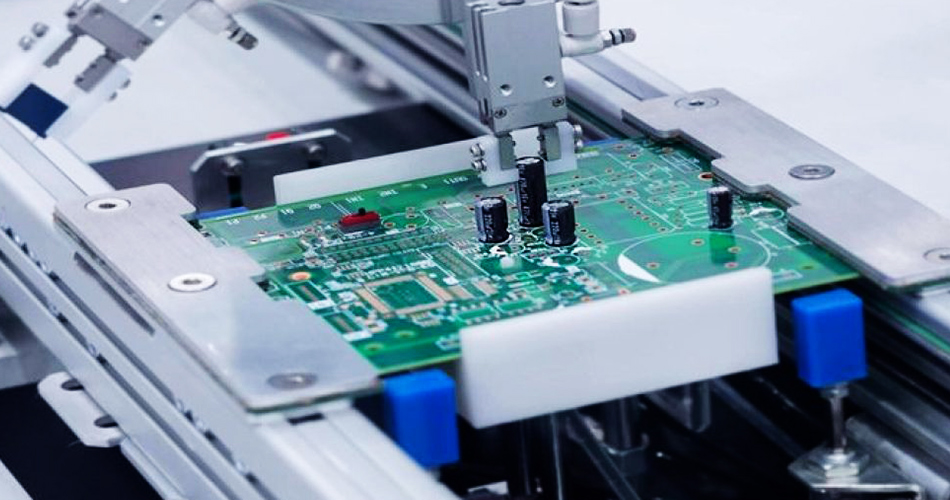

In the Electric Gardening Tool PCBA (Printed Circuit Board Assembly) manufacturing industry, production efficiency directly impacts a company's competitiveness and market performance. With continuous technological advancements, adopting advanced equipment has become a crucial means of improving production efficiency. Advanced equipment not only increases production efficiency but also ensures product quality and reduces production costs. This article will explore how to improve the production efficiency of Electric Gardening Tool PCBA factories by introducing advanced equipment, thereby achieving higher productivity and market competitiveness.

1. Introducing Automated Equipment

Automated equipment plays a vital role in Electric Gardening Tool PCBA manufacturing. Here are some aspects of introducing automated equipment:

Automatic Placement Machines: Automated placement machines can efficiently complete component placement tasks, greatly improving production speed and placement accuracy. Compared to manual placement, automated placement machines reduce errors and achieve high-density, precision placement.

Automatic Wave Soldering Machines and Reflow Soldering Machines: Automated wave soldering machines and reflow soldering machines are used for soldering electronic components, improving soldering quality and efficiency. Modern soldering equipment is typically equipped with advanced temperature control systems and automatic detection functions, ensuring the stability and consistency of soldering. 1. **Intelligent Inspection Equipment:** Introducing intelligent inspection equipment, such as Automated Optical Inspection (AOI) and X-ray Inspection (AXI), enables real-time monitoring and inspection of welding quality, component placement, and other issues. This equipment can quickly identify and correct defects in production, reducing rework rates and improving production efficiency.

2. Efficient Production Line Layout: The efficient application of advanced equipment also requires optimizing the production line layout to improve overall production efficiency:

Production Line Automation: Automated production line layouts reduce manual intervention and improve production continuity and efficiency. Automated production lines can automate the entire process from raw material input to finished product output, significantly increasing production capacity and consistency.

Flexible Production Line Configuration: Modular and flexible production line configurations can adapt to different production needs and product specifications. Flexible production line configurations allow for rapid adjustments to production processes and flows, improving the adaptability and efficiency of the production line.

Intelligent Logistics System: Introducing intelligent logistics systems, such as automated conveyor belts and material handling robots, can optimize material flow and management on the production line. Intelligent logistics systems can reduce material handling time and labor costs, improving the overall operational efficiency of the production line.

3. Implement Advanced Process Technologies

Advanced process technologies are also crucial for improving production efficiency:

Precision Manufacturing Technology: Employing high-precision manufacturing technologies, such as laser cutting and high-precision printing, improves the manufacturing accuracy and consistency of Electric Gardening Tool PCBAs. These technologies effectively reduce manufacturing errors, improving product quality and reliability.

Intelligent Production Control: Implementing intelligent production control systems utilizes data analysis and real-time monitoring technologies to optimize the production process. Intelligent production control systems can adjust production parameters and processes in real time, improving production efficiency and reducing production costs.

Green and Environmentally Friendly Technologies: Adopting environmentally friendly technologies, such as lead-free soldering and energy-saving equipment, reduces the environmental impact of the production process. These technologies not only meet environmental requirements but also reduce production costs, enhancing the company's social responsibility and market competitiveness.

4. Improve Equipment Maintenance and Management

To fully utilize the efficiency of advanced equipment, equipment maintenance and management are also essential:

Regular Maintenance and Upkeep: Establishing a regular equipment maintenance and upkeep system ensures the normal operation and long-term stability of equipment. Regular maintenance reduces equipment failure rates, extends equipment lifespan, and improves production efficiency.

Real-time Monitoring System: A real-time monitoring system is introduced to monitor and analyze equipment status and the production process in real time. Real-time monitoring can promptly detect equipment malfunctions and production anomalies, allowing for corrective action and ensuring smooth production.

Training and Technical Support: Operators are trained on advanced equipment to ensure they can operate and maintain it proficiently. Technical support and solutions are provided to help operators address various issues encountered during equipment use.

Conclusion:

By introducing advanced equipment, Electric Gardening Tool PCBA plants can significantly improve production efficiency, thereby achieving higher productivity and market competitiveness. Automated equipment, optimized production line layout, advanced process technologies, and equipment maintenance and management measures are all important aspects of improving production efficiency. The comprehensive application of these strategies can effectively improve production efficiency, ensure product quality, reduce production costs, and drive PCBA plants to success in the fiercely competitive market.

-

Delivery Service

-

Payment Options