- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industrial control PCBA Factory Production Efficiency Optimization: A Comprehensive Analysis from Equipment to Processes

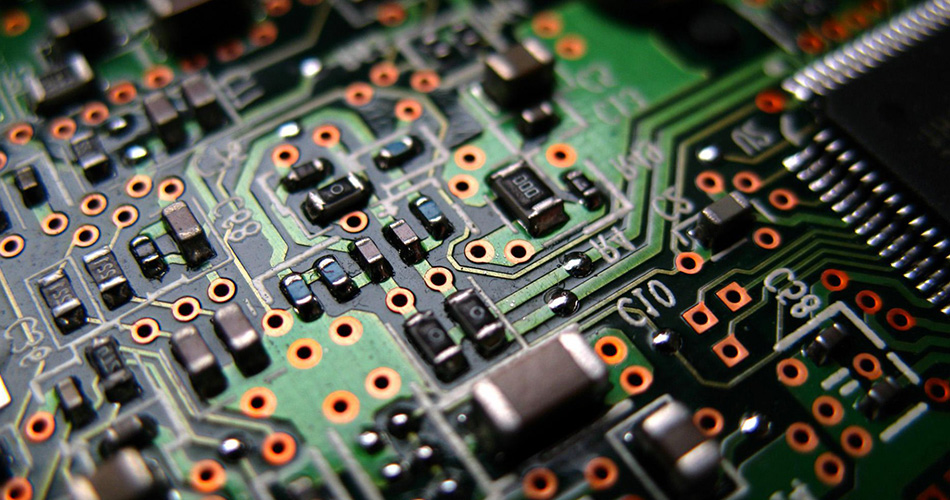

In the Industrial Control PCBA (Printed Circuit Board Assembly) manufacturing industry, optimizing production efficiency is key to enhancing competitiveness and meeting market demands. Production efficiency depends not only on advanced equipment but also on the design and management of production processes. This article will provide a comprehensive analysis of how to improve PCBA factory production efficiency through equipment and process optimization.

1. Equipment Optimization

Introduction of Advanced Equipment

Modern Industrial Control PCBA factories need to introduce advanced production equipment to improve efficiency. Advanced pick-and-place machines and reflow ovens can handle more component types and sizes, reducing production time. Automated equipment such as automated optical inspection (AOI) systems and automated test equipment (ATE) can also significantly improve production accuracy and efficiency.

Equipment Maintenance and Calibration

Regular equipment maintenance and calibration are crucial for ensuring production efficiency. The stability and accuracy of equipment directly affect production quality and speed. Factories should develop equipment maintenance plans to ensure all equipment is always kept in optimal condition, thereby reducing downtime and malfunctions.

Equipment Configuration Optimization

Optimizing equipment configuration can reduce bottlenecks on the production line. For example, grouping equipment for similar processes together or flexibly adjusting it according to production needs helps improve the overall efficiency of the production line. Furthermore, a rational arrangement of equipment layout to reduce material handling time can also significantly improve production efficiency.

2. Process Optimization

Process Standardization

Process standardization is the foundation for improving production efficiency. By establishing Standard Operating Procedures (SOPs), factories can ensure that all processes are performed according to consistent standards, thereby reducing errors and variations. Standardized processes also facilitate employee training and performance evaluation, improving overall production efficiency.

Lean Manufacturing

Lean manufacturing methods help Industrial Control factories identify and eliminate waste in production. Through lean manufacturing tools, such as Value Stream Mapping and 5S (Sort, Set in order, Shine, Standardize, Sustain), factories can optimize production processes, reduce unnecessary processes and operations, and improve production efficiency.

Real-Time Data Monitoring

Real-time data monitoring systems provide instant data on the production line, helping factory managers quickly identify and resolve problems in production. By analyzing production data, factories can adjust production strategies in real time, optimize production processes, and reduce downtime and bottlenecks.

Automated Processes

Introducing automated processes is a crucial means of improving production efficiency. Automated systems can complete repetitive, labor-intensive tasks, thereby increasing production speed and accuracy. For example, automated material handling systems and robotic welding systems can reduce manual intervention and improve production efficiency.

3. Personnel Training and Management

Employee Training

Employee skills and knowledge directly impact production efficiency. Regular employee training improves workers' operational skills, ensuring they can skillfully use equipment and perform production tasks. Training should also include knowledge of production processes and quality control to reduce production errors and improve efficiency.

Incentives and Management

Incentives and effective personnel management are also critical to production efficiency. By setting clear performance goals and reward mechanisms, factories can motivate employees to improve work efficiency. Simultaneously, good team management and communication ensure coordination and cooperation during the production process, reducing conflicts and problems.

Conclusion

Optimizing the production efficiency of a Industrial Control PCBA processing plant requires addressing both equipment and processes. Introducing advanced equipment, performing equipment maintenance and calibration, and optimizing equipment configuration are key to equipment optimization. Standardized processes, lean manufacturing, real-time data monitoring, and automated processes are important measures for process optimization. Furthermore, employee training and management are also crucial factors in improving production efficiency. By integrating these measures, PCBA factories can significantly improve production efficiency, meet market demands, and achieve business objectives.

Send Inquiry

-

Delivery Service

-

Payment Options