- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

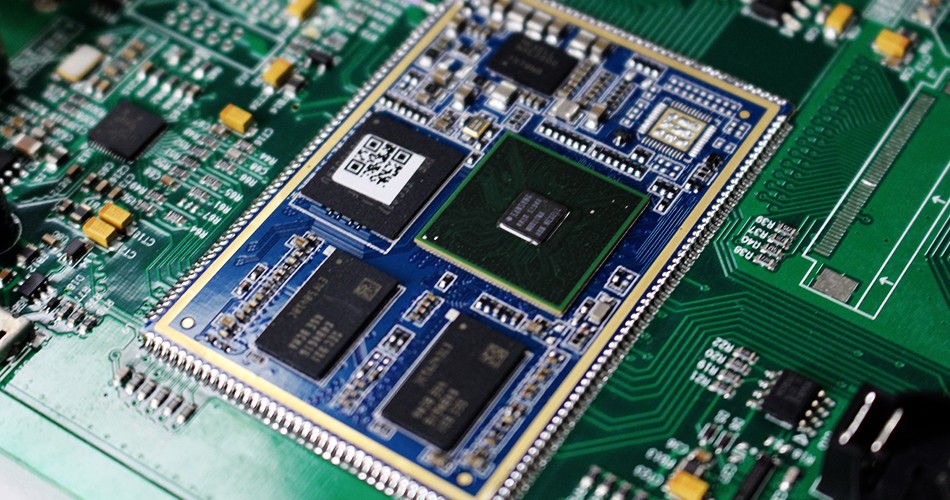

Multi-Task Production Capabilities: How to Choose the Right PCBA Factory?

In the PCBA (Printed Circuit Board Assembly) manufacturing industry, multi-task production capabilities have become a crucial indicator of factory competitiveness. With the diversification of market demands and the increasing complexity of production processes, selecting a PCBA factory with multi-task production capabilities is crucial to ensuring project success. This article will explore how to choose the right PCBA factory, particularly one that excels in multi-task production.

1. Definition of Multi-Task Production Capabilities

Multi-task production capabilities refer to a PCBA factory's ability to simultaneously handle different types and specifications of production tasks within the same production line or facility. This capability is crucial for meeting rapidly changing market demands, shortening lead times, and optimizing production resources. Factories with multi-task production capabilities typically exhibit greater flexibility and adaptability.

2. Key Factors in Selecting the Right PCBA Factory

When selecting a PCBA factory with multi-task production capabilities, consider the following key factors:

Flexibility of Production Equipment: Modern PCBA factories require versatile production equipment, such as adjustable placement machines and reflow ovens. These machines can handle electronic components of varying sizes and types, adapting to a variety of production tasks. Choosing a factory equipped with advanced, flexible production equipment ensures efficient and stable production lines when handling diverse projects.

Production Line Configuration: A factory's production line configuration should support rapid switching between production tasks. Factories with modular production lines can quickly adjust production settings based on demand, meeting the needs of small batches and high-mix production. Flexible production line configurations help improve production efficiency and shorten delivery times.

Process Capabilities and Adaptability: When selecting a PCBA factory with multi-tasking production capabilities, consider its process capabilities and adaptability. The factory should be able to handle complex circuit board designs, various soldering processes, and diverse testing requirements. Excellent process capabilities and adaptability are essential for ensuring product quality and meeting customer needs.

Technical Support and Engineering Team: A factory's technical support and engineering teams play a crucial role in multi-tasking production. They need to be able to quickly respond to production issues, provide technical support, and optimize production processes. Choosing a factory with strong technical support and an experienced engineering team will help resolve complex production issues.

Production Scheduling and Management Capabilities: Multi-tasking production capabilities rely not only on equipment and processes but also on efficient production scheduling and management systems. Factories should have advanced production management systems to efficiently schedule production tasks and optimize resources. Effective production scheduling ensures that various production tasks are completed on time and reduces production bottlenecks.

3. Advantages of Multi-Task Production Capabilities

Choosing a PCBA factory with multi-task production capabilities offers the following advantages:

Increased production flexibility: Factories that can handle multiple production tasks simultaneously can quickly adapt to market demand changes and provide flexible production solutions. This flexibility is crucial for addressing market fluctuations and individual customer needs.

Shortened delivery cycles: Multi-task production capabilities reduce production changeover time, improve production line utilization, and thus shorten delivery cycles. This helps meet customer demands for fast delivery and enhance customer satisfaction.

Optimized resource utilization: Multi-task production enables more efficient use of production resources, including equipment, personnel, and materials. By optimizing the allocation of production resources, factories can improve production efficiency and reduce production costs.

Improved product quality: Factories with multi-task production capabilities typically have higher process capabilities and production stability, resulting in improved product consistency and quality. High-quality production processes reduce rework and scrap, ensuring that the final product meets customer requirements.

Conclusion

In the PCBA manufacturing industry, selecting a factory with multi-tasking production capabilities is crucial to project success. By focusing on production equipment flexibility, production line configuration, process capabilities, technical support, and production management capabilities, companies can find the right PCBA factory to meet diverse production needs. A factory with multi-tasking capabilities not only improves production flexibility and efficiency, but also optimizes resource utilization and ensures product quality. Choosing the right PCBA factory can provide companies with a competitive advantage and help them achieve their business goals.

Send Inquiry

-

Delivery Service

-

Payment Options