- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Exploring Total Quality Management Strategies for PCBA Factories

2025-11-10

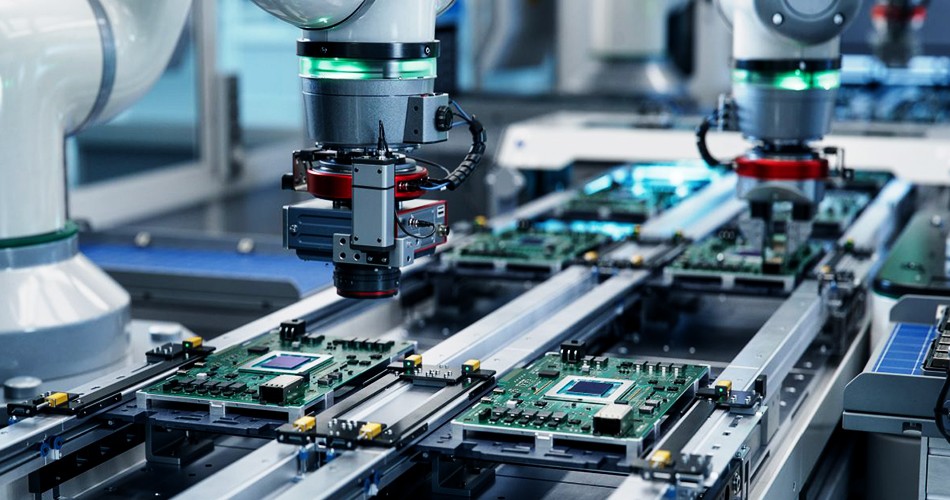

In the electronics manufacturing industry, the quality of PCBA (Printed Circuit Board Assembly) processing is crucial, directly impacting product performance, reliability, and market competitiveness. To ensure product quality, PCBA factories need to implement a comprehensive quality management strategy. This article will explore how PCBA factories can improve production efficiency and product quality through Total Quality Management (TQM).

1. The Concept of Total Quality Management

Total Quality Management (TQM) is an organization-wide management philosophy aimed at improving quality through continuous improvement and satisfying customer needs. TQM emphasizes the importance of every employee in quality management, ensuring that every step contributes to product quality.

Customer Orientation

The core of TQM is customer-centricity and a focus on customer needs and expectations. By deeply understanding customer feedback, PCBA factories can continuously adjust and optimize production processes to improve customer satisfaction.

Full Employee Involvement

TQM emphasizes the participation and responsibility of every employee, encouraging them to proactively identify and resolve problems in their daily work. This culture fosters a sense of belonging and work enthusiasm among employees, ultimately improving overall production efficiency.

2. Core Elements of Quality Management

PCBA factories should focus on the following core elements when implementing Total Quality Management:

2.1 Quality Planning

Developing a detailed quality plan is crucial during the production process. Factories should clearly define quality objectives and develop a corresponding implementation plan, including resource allocation, personnel training, and process standards.

2.2 Quality Control

Quality control is a crucial step in ensuring that the production process meets standards. Factories should utilize a variety of inspection methods, such as automated optical inspection (AOI), functional testing, and environmental testing, to promptly identify and resolve production issues.

2.3 Quality Improvement

Through continuous data analysis, PCBA factories can identify bottlenecks and deficiencies in the production process. Implementing management tools such as Six Sigma or Lean Production can optimize processes, reduce scrap, and improve production efficiency.

3. Data-Driven Decision-Making

Data collection and analysis are key to Total Quality Management. PCBA factories should establish a comprehensive data management system to monitor various production process indicators in real time.

Key Performance Indicators (KPIs)

KPIs are set to quantify the achievement of quality goals. By analyzing KPI data, factories can adjust production strategies in a timely manner to ensure efficient and stable production processes.

Problem Tracing

Data analysis allows factories to quickly trace the root causes of quality issues. This analysis not only helps solve current problems but also provides guidance for future quality improvements.

4. Training and Culture Building

The success of total quality management depends on employee support and participation. PCBA factories should prioritize employee training and culture building to enhance overall quality.

Regular Training

Provide employees with ongoing skills training and quality management knowledge to help them understand the importance and methods of quality management and strengthen their quality control capabilities.

Establishing a Quality Culture

Through incentive mechanisms and team activities, cultivate a quality culture of full employee participation. Employees are encouraged to submit improvement suggestions and work together to achieve higher product quality.

Conclusion

Total quality management is an effective strategy for improving PCBA processing quality. Through customer orientation, full employee participation, data-driven decision-making, and continuous improvement, PCBA factories can achieve stable and improved product quality. In the fierce market competition, implementing total quality management can not only improve customer satisfaction, but also enhance the core competitiveness of the enterprise and lay a solid foundation for long-term development.

-

Delivery Service

-

Payment Options