- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can we improve the reliability of Medical PCBA products through strict quality standards?

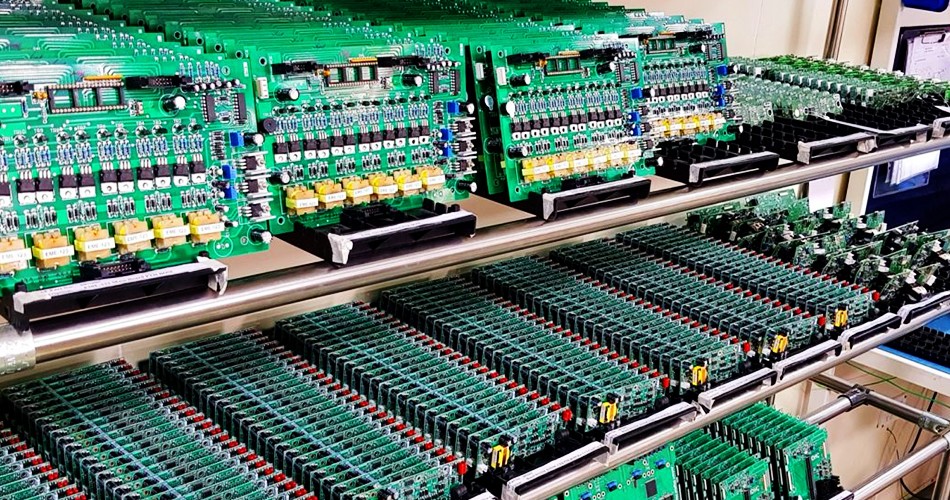

In modern electronic product manufacturing, the quality of Medical PCBA (Printed Circuit Board Assembly) processing is directly related to product performance and reliability. To survive in the fiercely competitive market, companies must adhere to strict quality standards to ensure product reliability. This article will explore how to improve the reliability of PCBA products by implementing high-standard quality management.

1. The Importance of Quality Standards

Quality standards are the foundation for ensuring that products meet industry requirements and customer expectations. For Medical PCBA processing, quality standards encompass not only every step of the production process but also aspects such as raw material selection, production processes, and testing procedures.

Increasing Customer Trust

Strict quality standards enable companies to provide high-quality products, enhancing customer trust. Trust is the foundation of long-term relationships, and reliable products encourage repeat purchases and recommendations.

Reducing Failure Rates

Implementing high-standard quality management can significantly reduce product failure rates. Through effective monitoring and testing, companies can promptly identify potential problems and prevent substandard products from entering the market.

2. Establishing Strict Quality Standards

To enhance the reliability of Medical PCBA products, companies should establish strict quality standards in the following areas:

2.1 Raw Material Control

Selecting qualified raw materials is the first step in ensuring product quality. Companies should ensure that the electronic components they use meet international standards and require suppliers to provide relevant quality certifications. Furthermore, they should regularly inspect raw materials to ensure they meet quality requirements.

2.2 Standardizing Production Processes

Standardized production processes ensure controllability and consistency in the production process. Companies should develop detailed process flows that clearly define the operating procedures for each step, including soldering, assembly, and testing. Through standardization, the impact of human factors on product quality can be reduced.

2.3 Improving Inspection Processes

Establishing a comprehensive inspection process is key to ensuring product reliability. Companies should conduct rigorous quality inspections at all stages of production, including incoming material inspection, in-process inspection, and final inspection. The introduction of advanced inspection equipment, such as automated optical inspection (AOI) and X-ray inspection, can efficiently and accurately detect defects.

3. Establishing a Quality Management System

Establishing an effective quality management system (QMS) is fundamental to ensuring the reliability of Medical PCBA products. Companies should implement systematic quality management in accordance with international standards, such as ISO 9001.

Continuous Improvement

Through internal audits and management reviews, companies can promptly identify deficiencies in quality management and implement continuous improvement. They should also pay attention to customer feedback and market changes, optimizing quality management processes to adapt to evolving needs.

Training and Education

Regularly provide employee quality management training to enhance their quality awareness and skills. Employees are the direct implementers of quality management, and improving their quality can effectively improve product reliability.

4. Data-Driven Quality Control

Using data analytics, companies can better monitor and manage product quality. By analyzing production process and test data, quality issues can be promptly identified and resolved.

Key Performance Indicators (KPIs)

Set key performance indicators (KPIs) related to product reliability to monitor quality performance during the production process. Regularly analyzing this data can identify potential quality risks, allowing timely improvement measures to be taken.

Problem Tracing and Analysis

Once a quality problem is discovered, companies should quickly trace and analyze the problem to identify the root cause and develop appropriate corrective measures. A data-driven approach can effectively improve the efficiency and accuracy of problem solving.

Conclusion

PCBA manufacturers can significantly enhance product reliability through strict quality standards. Implementing high-standard management in areas such as raw material control, standardized production processes, improved testing procedures, the establishment of a quality management system, and data-driven quality control can effectively reduce failure rates, enhance customer trust, and lay a solid foundation for the company's long-term development. In the electronics manufacturing industry, reliable products are key to gaining a competitive advantage.

Send Inquiry

-

Delivery Service

-

Payment Options