- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

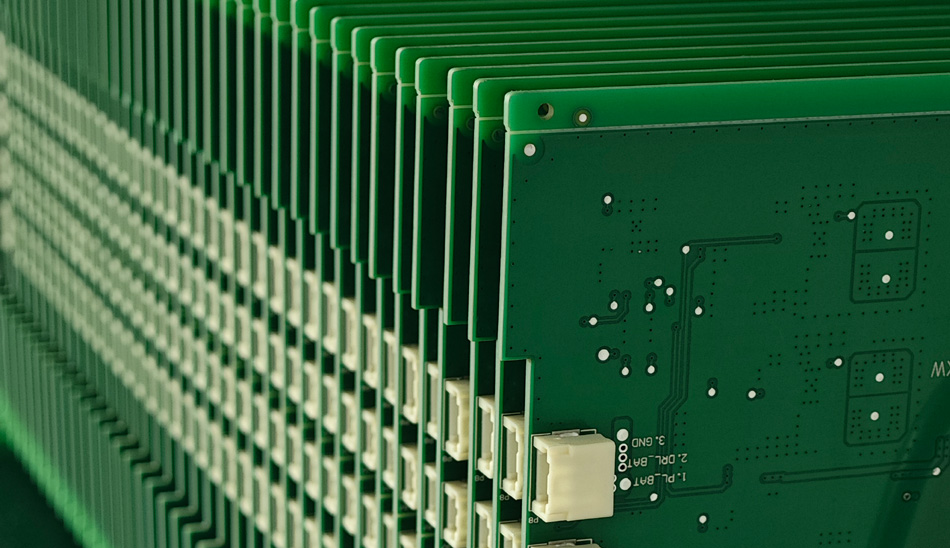

From Flexible PCBs to Rigid-Flex PCBs: The Technical Support Capabilities of PCBA Factories

2025-11-01

In modern electronic product design, flexible PCBs (FPCBs) and rigid-flex PCBs (Rigid-Flex PCBs) have garnered widespread attention due to their superior performance and design flexibility. These advanced PCB types play a vital role in meeting the demands of miniaturization and high performance. This article will explore the technical support capabilities of PCBA (Printed Circuit Board Assembly) factories in transitioning from flexible PCBs to rigid-flex PCBs.

1. Advantages of Flexible PCBs and Rigid-Flex PCBs

Features of Flexible PCBs

Flexible PCBs offer excellent flexibility and adaptability, enabling them to accommodate complex three-dimensional designs. This flexibility has led to their widespread use in smartphones, wearables, and medical devices.

Advantages of Rigid-Flex PCBs

Rigid-flex PCBs combine the advantages of rigid and flexible PCBs, providing both rigid support and flexible layout. They are increasingly used in aerospace, automotive, and high-end consumer electronics, effectively saving space and weight.

2. PCBA Factory's Technical Support Capabilities

2.1 Equipment and Process Technology

Advanced Production Equipment

PCBA factories require advanced equipment for the production of flexible PCBs and rigid-flex boards. High-precision placement machines and laser cutting equipment are key to ensuring production quality. These machines can meet the demands of high-precision, high-density production and ensure accurate component placement.

Professional Process Flow

PCBA factories should establish specialized process flows for flexible PCBs and rigid-flex boards. This encompasses every step, from material selection and lamination to placement, soldering, and testing. Each step requires strict control to ensure the performance and reliability of the final product.

2.2 R&D Capabilities and Technological Innovation

Continuous R&D Investment

PCBA factories need to continuously invest in R&D to keep pace with advances in flexible PCB and rigid-flex board technology. Close collaboration with material suppliers and equipment manufacturers allows factories to obtain the latest material and technology information to optimize production processes.

Application of New Materials

The production of flexible PCBs and rigid-flex boards requires specific material support. PCBA factories should master the application of new flexible and substrate materials to improve product performance and durability.

3. Quality Control and Management

A Comprehensive Quality Management System

Quality control is crucial during the PCBA process. Factories should establish a comprehensive quality management system, including raw material inspection, production process monitoring, and finished product testing, to ensure that every circuit board meets quality standards.

Advanced Inspection Technology

For flexible PCBs and rigid-flex boards, PCBA factories should utilize advanced inspection technologies such as automated optical inspection (AOI), X-ray inspection, and thermal analysis. These inspection methods can promptly identify potential problems during the production process and improve product reliability.

4. Personnel Training and Skill Enhancement

Professional Training for Technical Staff

PCBA factories should regularly provide professional training to their employees to enhance their operational skills in flexible PCB and rigid-flex board production. Through continuous training and knowledge updates, they ensure that employees are proficient in advanced production techniques.

Teamwork and Communication

Good teamwork and communication can improve production efficiency. Factories should encourage communication between departments and ensure the timely transfer of information, allowing for the rapid resolution of production issues.

Conclusion

From flexible PCBs to rigid-flex boards, the technical support capabilities of PCBA factories play a key role in driving the miniaturization and performance of electronic products. By introducing advanced equipment, optimizing processes, strengthening quality management, and upgrading employee skills, PCBA factories can meet market demand for high-quality, highly reliable electronic products. As the electronics industry continues to evolve, PCBA factories should continue to monitor technological innovation and market trends to enhance their technical support capabilities and ensure their competitive advantage.

-

Delivery Service

-

Payment Options