- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Delivery Challenges and Solutions for PCBA Factories

2025-10-20

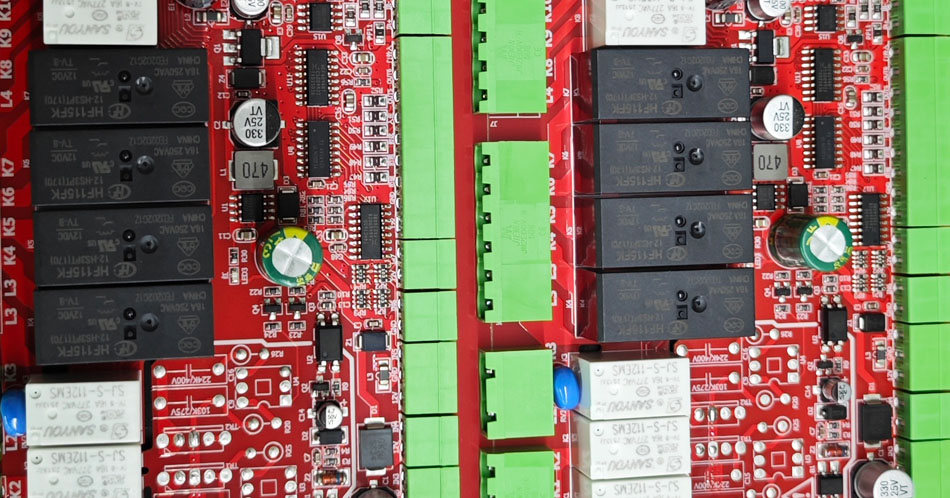

In today's highly competitive electronics manufacturing market, PCBA (Printed Circuit Board Assembly) factories face multiple delivery challenges. These challenges not only impact production efficiency but can also negatively impact customer satisfaction and market reputation. To address these challenges, factories need to implement effective solutions. This article will explore common delivery challenges faced by PCBA factories and their corresponding solutions.

1. Delivery Challenges

Supply Chain Instability

A PCBA factory's delivery capabilities are impacted by its supply chain. Unstable component supply can lead to production delays, especially during periods of raw material shortages or surges in market demand. Factors such as suppliers' untimely delivery and material price fluctuations can also impact production plans.

Complex Production Process

The PCBA manufacturing process involves multiple steps, including material procurement, component placement, soldering, and testing. Delays at any stage can extend overall delivery time. Especially when working with complex, multi-layer boards, the complexity of the production process can further increase delivery challenges.

Order Fluctuations

Market demand fluctuates rapidly, and PCBA factories often have to cope with fluctuating order volumes. During peak periods, surges in orders can lead to insufficient production capacity, while during periods of reduced demand, excess inventory can create challenges for delivery management.

2. Solutions

Strengthening Supply Chain Management

To address the challenges of supply chain instability, PCBA factories should establish stable supplier relationships. Working with multiple suppliers can reduce the risk of problems associated with a single supplier. Furthermore, factories can use supply chain management software to forecast and plan material needs, ensuring timely procurement of required components.

Optimizing Production Processes

Optimizing production processes is a key measure to address production delays. Factories can improve efficiency and shorten processing times by introducing advanced automated equipment. Furthermore, implementing lean manufacturing methods can identify and eliminate waste within the process, ensuring efficient integration of all links.

Flexible Production Planning

To manage order fluctuations, PCBA factories should develop flexible production plans. They can adjust production line operations and human resource allocation based on market demand. During peak periods, temporary workers or shift work can be added to maintain production capacity. During off-peak periods, resources can be rationally deployed to reduce production costs.

Strengthen Communication and Collaboration

PCBA factories should enhance communication and collaboration across their departments. Production, procurement, and sales teams should regularly share information to ensure timely understanding of market demand and inventory levels. Furthermore, maintaining good communication with customers and providing timely feedback on production progress and delivery schedules can enhance customer trust.

Data-Driven Decision Making

Data analytics tools can help PCBA factories monitor production progress and delivery status in real time. By collecting and analyzing historical delivery data, factories can identify potential bottlenecks and issues, thereby developing targeted improvement measures to enhance delivery capabilities.

Conclusion

PCBA factories face numerous challenges in the delivery process, but effective solutions can significantly improve delivery capabilities. Strengthening supply chain management, optimizing production processes, flexibly responding to order fluctuations, enhancing internal communication, and leveraging data-driven decision making are all key measures to improve PCBA processing efficiency. With intensifying market competition, PCBA factories must continuously refine these measures to ensure on-time delivery, meet customer needs, and maintain a competitive position in the industry.

-

Delivery Service

-

Payment Options