- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can PCBA factories ensure timely component supply through supply chain management?

2025-10-21

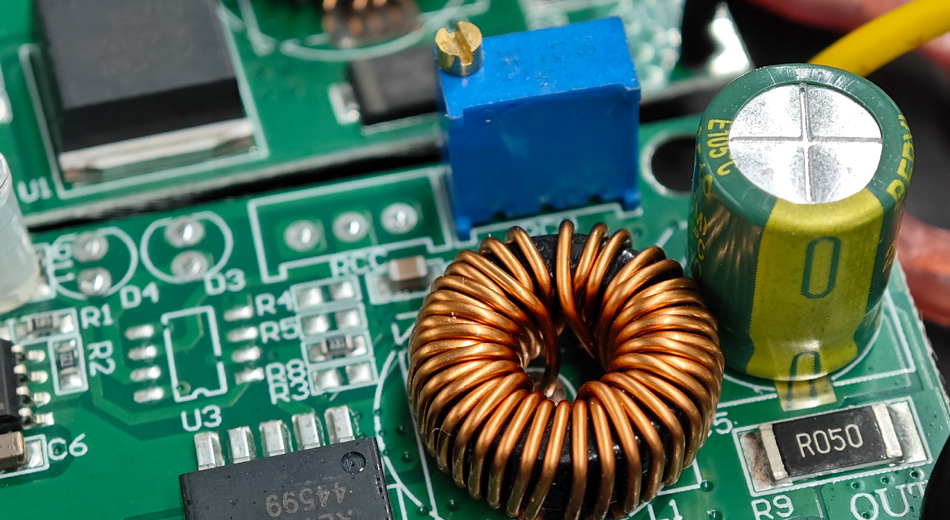

In the PCBA (Printed Circuit Board Assembly) manufacturing industry, timely component supply is a key factor in ensuring smooth production. Effective supply chain management can help factories maintain stable production capacity amid market fluctuations and avoid delivery delays caused by material shortages. This article will explore how PCBA factories can ensure timely component supply through supply chain management.

1. Establishing Stable Supplier Relationships

Selecting High-Quality Suppliers

PCBA factories must first establish partnerships with multiple high-quality suppliers. These suppliers should have a good reputation, stable supply capacity, and high-quality products. By evaluating suppliers' delivery records and customer reviews, factories can select the most reliable partners to ensure timely component supply.

Long-Term Cooperation Agreements

Signing long-term cooperation agreements with suppliers not only locks in pricing but also improves supply reliability. Contracts can include regular delivery schedules to ensure a stable supply of materials even during peak demand periods.

2. Optimizing Procurement Processes

Implementing Just-in-Time (JIT) Management

Implementing JIT management is an effective supply chain management strategy. PCBA factories can accurately calculate the required component quantities and delivery times based on production plans and actual demand. This management approach helps reduce inventory costs and mitigate the risks associated with excess or insufficient materials.

Dynamic Procurement Strategy

PCBA factories should flexibly adjust their procurement strategies based on market fluctuations and order status. They can increase procurement volumes when demand surges, and reduce them when demand decreases. This dynamic procurement strategy helps factories cope with market uncertainty.

3. Strengthen Inventory Management

Implementing an Intelligent Inventory Management System

Introducing an intelligent inventory management system allows for real-time monitoring of inventory levels and material consumption. Through system data analysis, factories can predict component demand in advance and ensure timely replenishment. This systematic management approach improves component supply efficiency and reduces the risk of stockouts.

Safety Stock Setting

When developing an inventory management strategy, factories should set a safety stock level to cope with unexpected increases in demand or supply delays. When inventory falls below the safety level, the system automatically issues an alert, alerting the procurement team to replenish materials promptly, ensuring uninterrupted production.

4. Strengthen Supply Chain Communication

Regular Communication with Suppliers

PCBA factories should regularly communicate with suppliers to understand market trends and component supply and demand. By establishing close partnerships with suppliers, factories can obtain relevant information in a timely manner and make corresponding adjustments. This proactive communication approach helps reduce supply chain uncertainty and ensure the timely supply of components.

Cross-Departmental Collaboration

To ensure a smooth supply chain, PCBA factories should also strengthen collaboration among various departments within the factory. Production, procurement, and sales teams need to regularly share information to understand market demand and inventory levels, thereby formulating more effective procurement plans and production schedules.

5. Strategies for Responding to Emergencies

Diversified Supply Chain

PCBA factories should consider establishing a diversified supply chain, collaborating with multiple suppliers to reduce the risk of problems associated with a single supplier. If a supplier is unable to deliver on time, the factory can quickly obtain the required materials from alternative suppliers to ensure continued production.

Developing an Emergency Plan

Developing an emergency plan is also a key strategy for ensuring the timely supply of components. Factories can develop appropriate response measures for various emergencies, such as supplier delays and natural disasters, to ensure continued production under adverse conditions.

Conclusion

In the PCBA industry, the timely supply of components is essential for smooth production. By establishing stable supplier relationships, optimizing procurement processes, strengthening inventory management, enhancing supply chain communication, and developing contingency plans, PCBA factories can effectively improve their supply chain management and ensure timely component supply. This not only improves production efficiency but also strengthens the company's competitive advantage in the market.

-

Delivery Service

-

Payment Options