- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

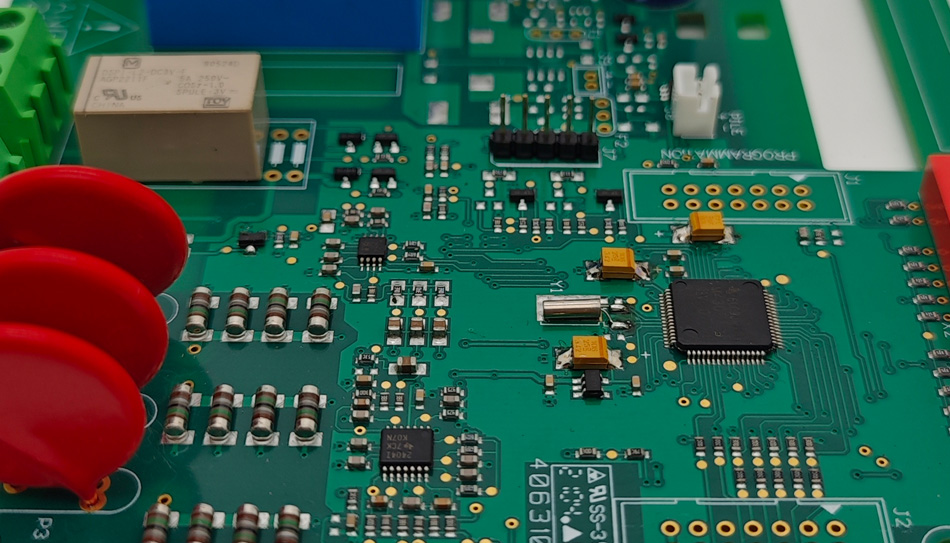

How to Choose a PCBA Factory with Efficient Delivery Capabilities?

2025-10-19

In the highly competitive electronics manufacturing industry, choosing a PCBA (Printed Circuit Board Assembly) factory with efficient delivery capabilities is crucial. Effective delivery capabilities not only meet customer needs but also help companies gain a competitive edge in the market. This article will provide some key considerations when selecting a PCBA factory to ensure you make an informed decision.

1. Understanding the Manufacturer's Production Capacity

Production Scale and Equipment

When choosing a PCBA factory, first consider its production scale and equipment. Larger factories typically have more advanced production equipment and technology, enabling them to handle large orders while maintaining high efficiency. Understanding the factory's level of automation is also crucial, as automated equipment can significantly improve production speed and accuracy.

Production Flexibility

In addition to production scale, a manufacturer's production flexibility is equally important. Factories with flexible production capabilities can quickly adjust production plans to accommodate urgent orders and meet specific customer needs. Understanding a factory's capabilities in small-batch and custom production can help you assess its responsiveness.

2. Evaluating Delivery Record and Reputation

Historical Delivery Record

Examining a PCBA factory's historical delivery record is an important indicator of its delivery capabilities. Choosing a factory with a track record of on-time delivery can reduce the risk of future delivery delays. Understanding their customer base and industry experience can also help you better assess their credibility.

Customer Reviews and Feedback

Reading customer reviews and feedback can provide firsthand information on a factory's delivery capabilities. Communicating with existing customers to understand their opinions on the factory's delivery capabilities and service quality can provide additional insights.

3. Consider Quality Control Measures

Strict Quality Management System

An efficient PCBA factory must not only produce quickly but also ensure product quality. Choosing a factory with strict quality control measures is essential. Finding out whether they hold international certifications such as ISO can help you assess their quality management capabilities.

Quality Inspection Process

It is also crucial to confirm the quality inspection processes implemented by the factory during production. Find out whether they have advanced testing equipment (such as AOI and X-ray) to ensure that products meet quality standards at every stage, avoiding rework and delays caused by quality issues.

4. Supply Chain Management Capabilities

Material Supply Reliability

Delivery capacity is closely related to the timely supply of raw materials. Choosing a PCBA factory with a stable material supply chain ensures quick access to required materials even during peak production periods. Furthermore, understanding whether the factory works with multiple suppliers can mitigate the risk of issues arising from a single supplier.

Procurement and Inventory Management

A factory's procurement and inventory management capabilities also impact its delivery capabilities. A factory with an efficient inventory management system can replenish materials promptly, avoiding production delays caused by shortages. Inquiring about the factory's experience and implemented strategies in this area will help you make a decision.

5. Strengthen Communication and Support

Customer Service and Support

Excellent customer service is an essential factor when selecting a PCBA factory. A factory with good communication skills will respond promptly to customer needs and questions, ensuring a smooth and seamless experience. Understanding the professionalism and responsiveness of the factory's customer support team can provide additional confidence.

On-site Communication and Visits

If conditions permit, an in-person factory visit is also highly beneficial. By gaining a firsthand understanding of the factory's production environment and team, you can gain a direct understanding of its production capabilities and expertise.

Conclusion

Choosing a PCBA factory with efficient delivery capabilities is crucial to ensuring project success. By comprehensively evaluating factors such as production capacity, delivery record, quality control, supply chain management, and customer service, you can find a partner that suits your needs. In today's rapidly changing market, choosing a reliable PCBA factory will provide strong support for your product development and marketing.

-

Delivery Service

-

Payment Options