- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

PCBA Factory Cost Structure Analysis: How to Choose a Cost-Effective Supplier?

2025-10-18

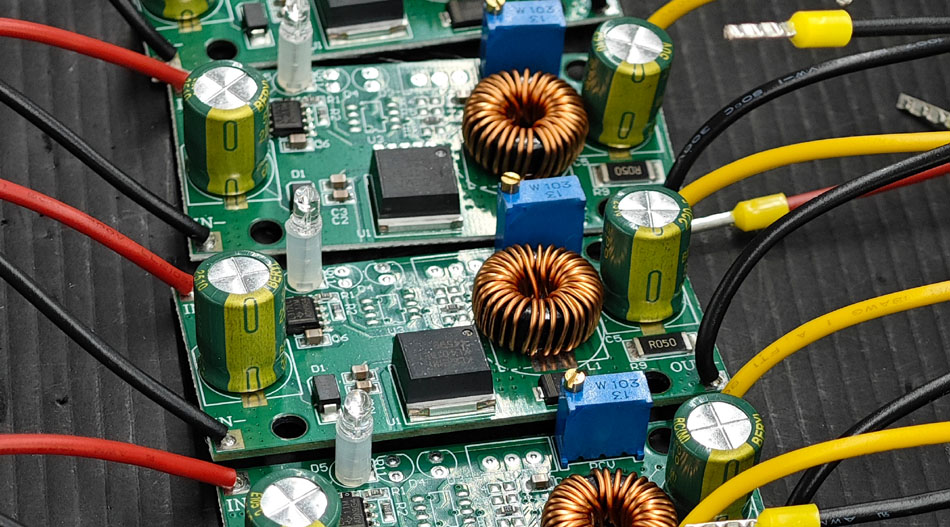

In the PCBA (Printed Circuit Board Assembly) processing industry, selecting the right supplier is crucial for controlling costs and improving product quality. Understanding the cost structure of a PCBA factory is key to making an informed choice. This article will analyze the cost structure of a PCBA factory and provide strategies for selecting a cost-effective supplier.

1. PCBA Factory Cost Structure

Material Costs

Material costs, including circuit boards, components, solder, and more, are typically the largest expense in PCBA processing. The choice of materials directly impacts product performance and cost, so when selecting a supplier, focus on material quality and pricing.

Labor Costs

Labor costs include worker wages, benefits, and training expenses. In factories with low levels of automation, labor costs can account for a significant proportion. Therefore, evaluating a supplier's production efficiency and employee skill level can help companies reduce these costs.

Equipment Costs

Equipment costs refer to the purchase and maintenance costs of the machinery and equipment required for PCBA processing. The supplier's equipment upgrades, technical level, and maintenance capabilities all impact production efficiency and product quality.

Operating Costs

Operating costs include administrative expenses, warehousing costs, and logistics costs. These indirect costs have a significant impact on the overall project profitability. A reasonable operating cost structure can help companies gain an advantage in market competition.

2. Selecting Cost-Effective Suppliers

Evaluating Material Quality and Price

When selecting a supplier, first evaluate the quality and price of the materials they provide. By requesting quotes and comparing samples, ensure that the selected materials meet product requirements and are within a reasonable price range. Comparing multiple suppliers can help companies find the most cost-effective option.

Consider Production Capacity and Delivery Capacity

When evaluating suppliers, consider not only their price but also their production capacity and delivery capabilities. A supplier's production capacity determines whether they can meet order requirements, while good delivery capabilities ensure timely project completion. Selecting a supplier with flexible production capabilities and a stable delivery record is an effective strategy for reducing overall costs.

Inspecting the Supplier's Technical Capacity

Technical capacity directly impacts the efficiency and quality of PCBA processing. When selecting a supplier, consider whether they have advanced production equipment and technology. High-quality technical support can help companies reduce failure rates during processing and improve production efficiency.

Evaluate Service Quality and Support

Excellent service quality and technical support are crucial to the long-term success of business partnerships. When selecting a supplier, focus on after-sales service, responsive technical support, and customer feedback. High-quality service ensures timely resolution of issues and avoids unnecessary losses.

Focus on Financial Stability

The supplier's financial health is also crucial. Financially stable suppliers are more able to sustain operations amidst market fluctuations, mitigating the risk of supplier bankruptcy or financial mismanagement. When selecting a supplier, review the supplier's financial statements or credit rating.

Conclusion

In the PCBA manufacturing industry, selecting a cost-effective supplier is crucial for cost control and product quality improvement. By thoroughly analyzing the cost structure of a PCBA factory, companies can better understand the cost components of each process and develop supplier selection strategies based on this information. Evaluating material quality, production capacity, technical expertise, service quality, and financial stability are all key factors in selecting a high-quality supplier. By taking these measures, companies can not only optimize procurement costs but also enhance market competitiveness and drive long-term growth.

-

Delivery Service

-

Payment Options