- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does procurement management at a PCBA factory impact overall costs?

2025-10-15

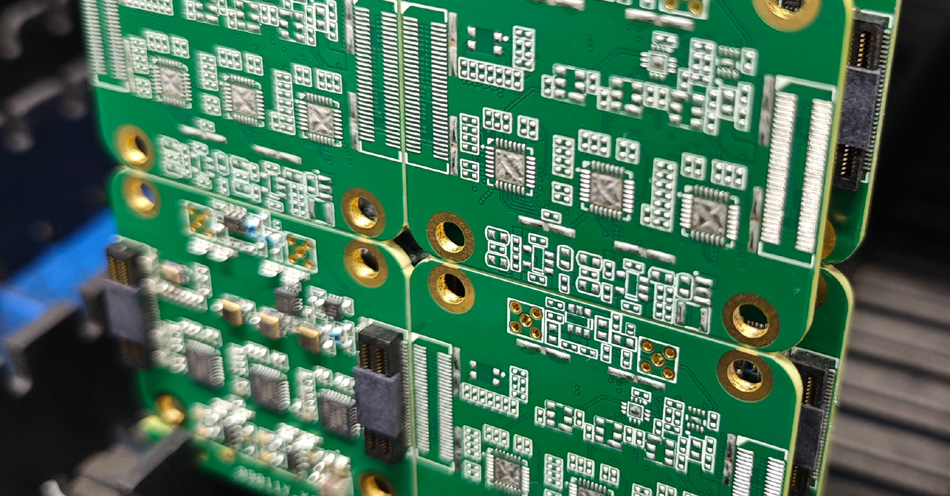

In the PCBA (Printed Circuit Board Assembly) manufacturing industry, procurement management involves more than just procuring materials; it also directly impacts overall production cost control. Effective procurement management can reduce raw material costs, improve production efficiency, and ultimately enhance a company's competitiveness. This article will explore how procurement management at a PCBA factory impacts overall costs.

1. Material Selection and Cost Control

Selecting Cost-Effective Suppliers

In PCBA manufacturing, material quality and price directly impact production costs. By establishing partnerships with multiple suppliers, companies can select cost-effective suppliers based on their needs, ensuring material quality while reducing procurement costs. In the long run, establishing stable partnerships with high-quality suppliers can offer more favorable pricing and service.

Bulk Purchasing and Negotiation

Bulk purchasing is an effective strategy for reducing unit costs. By negotiating with suppliers for preferential pricing on bulk purchases, PCBA factories can significantly reduce material costs. Furthermore, regularly evaluating supplier performance and engaging in price negotiations can help further optimize procurement expenditures.

2. The Impact of Inventory Management

Inventory Turnover

Efficient inventory management can improve inventory turnover and reduce capital tie-up. Streamlining procurement management ensures that material purchases match production demand, avoiding excess inventory and capital constraints. Improved inventory turnover not only reduces holding costs but also improves capital efficiency.

Avoiding Stockouts and Overstocks

Effective procurement management helps companies balance inventory, avoiding production delays caused by stockouts or capital waste caused by overstocks. Through accurate demand forecasting and flexible procurement strategies, PCBA factories can ensure the timely supply of materials needed for production.

3. Production Efficiency and Quality Assurance

Ensuring Material Quality

Procurement management is directly related to material quality, which is a key factor affecting product quality. High-quality raw materials reduce rework and scrap during production, thereby lowering overall production costs. By implementing rigorous supplier evaluation and material inspection processes, companies can ensure that purchased materials meet quality standards.

Reducing Production Risk

Stable procurement management can reduce risks in the production process. For example, timely raw material supply can prevent production delays caused by stockouts. Furthermore, a sound procurement strategy can mitigate the risk of raw material price increases due to market fluctuations, helping companies maintain cost stability.

4. Supply Chain Collaboration and Communication

Strengthening Supply Chain Collaboration

Good procurement management goes beyond simply procuring materials; it also involves close collaboration with suppliers. Through information sharing and communication, PCBA factories can better forecast demand and coordinate supply, ensuring a smooth production process and further reducing overall costs.

Supply Chain Flexibility

In a rapidly changing market environment, flexible procurement management can help companies quickly respond to demand changes. By adjusting procurement strategies promptly, companies can ensure production continuity while reducing unnecessary costs.

Conclusion

Procurement management plays a crucial role in PCBA processing and directly impacts overall production costs. By selecting cost-effective suppliers, optimizing inventory management, ensuring material quality, and strengthening supply chain collaboration, companies can effectively control costs and improve production efficiency. In the face of fierce market competition, scientific and rational procurement management will be a key support for the sustainable development of PCBA factories.

-

Delivery Service

-

Payment Options