- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Achieve a Win-Win Between Cost and Quality in PCBA Manufacturing?

2025-10-16

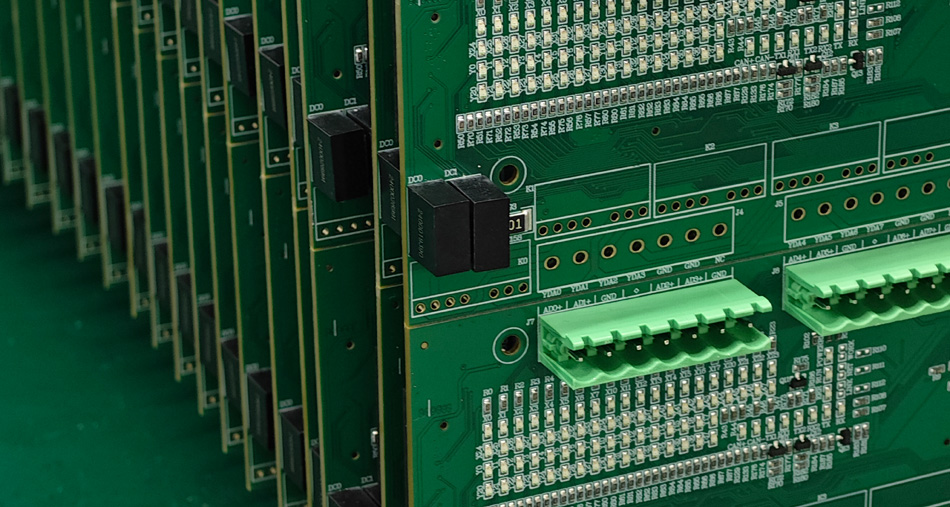

In the PCBA (Printed Circuit Board Assembly) manufacturing industry, achieving a win-win between cost and quality is the goal of every manufacturer. With intensifying market competition, companies must not only control costs but also ensure product quality to meet customers' high standards and expectations. This article will explore how to achieve a balance between cost and quality in PCBA manufacturing.

1. Understanding the Relationship between Cost and Quality

Balancing Cost and Quality

In PCBA manufacturing, cost and quality are often interrelated. Reducing costs may lead to compromises in materials or processes, thus affecting product quality; conversely, pursuing high quality may increase production costs. Therefore, companies need to find a balance to ensure that products meet quality requirements while staying within budget.

Identifying Influencing Factors

Factors that influence cost and quality include material selection, production processes, equipment investment, and human resource management. Understanding how these factors interact can help companies develop effective strategies.

2. Optimizing Material Selection

Choosing the Right Material

Material costs often account for a significant proportion of PCBA manufacturing costs. By evaluating the cost-effectiveness of different materials, companies can select cost-effective materials that meet product performance requirements. Furthermore, establishing long-term relationships with reliable suppliers ensures better pricing and quality assurance during the procurement process.

Consider Material Standardization

Using standardized materials and components can reduce procurement and inventory costs while streamlining the production process. This approach helps improve production efficiency and reduce material waste, achieving a win-win situation in terms of both cost and quality.

3. Improving Production Processes

Introducing Advanced Production Technologies

Adopting advanced production technologies and equipment can significantly improve production efficiency and product quality. For example, automated production lines and intelligent testing equipment can reduce human error and enhance machining accuracy. While the initial investment may be higher, these technologies can reduce overall production costs in the long run.

Implementing Lean Production

Lean production emphasizes eliminating waste and optimizing processes. Through lean management, companies can identify and eliminate unnecessary steps in the production process, reducing production costs and improving product consistency and quality.

4. Strengthening Employee Training and Engagement

Train employees regularly.

Highly qualified employees are crucial to ensuring product quality. Companies should conduct regular training to enhance their technical skills and quality awareness. During training, emphasize how to balance cost and quality in production, ensuring employees understand the impact of their work on overall quality.

Encourage Employee Participation in Improvement

Establish an employee feedback mechanism to encourage employees to submit improvement suggestions. Problems discovered by employees during actual production often provide important clues to improving quality and reducing costs. Companies should prioritize this feedback and promptly implement corrective measures.

5. Implement Total Quality Management

Establish a Quality Management System

Implementing a Total Quality Management (TQM) system can help companies strengthen quality control at every stage. From design and procurement to production and after-sales service, TQM ensures that every step meets quality standards, thereby reducing rework and complaint costs.

Data-Driven Decision Making

Using data analytics tools to monitor and analyze quality data during the production process can quickly identify and correct problems. Data-driven decision making improves response time and ensures continuous optimization of the production process.

Conclusion

Achieving a win-win situation between cost and quality in PCBA manufacturing is not easy, but by optimizing material selection, improving production processes, strengthening employee training, and implementing TQM, companies can find an effective balance. Faced with fierce market competition, companies must continue to focus on optimizing these two aspects to enhance their market competitiveness and achieve sustainable development. Through these strategies, companies can not only control costs but also ensure product quality and meet customer expectations.

-

Delivery Service

-

Payment Options