- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can PCBA factories reduce production costs through automation?

2025-10-14

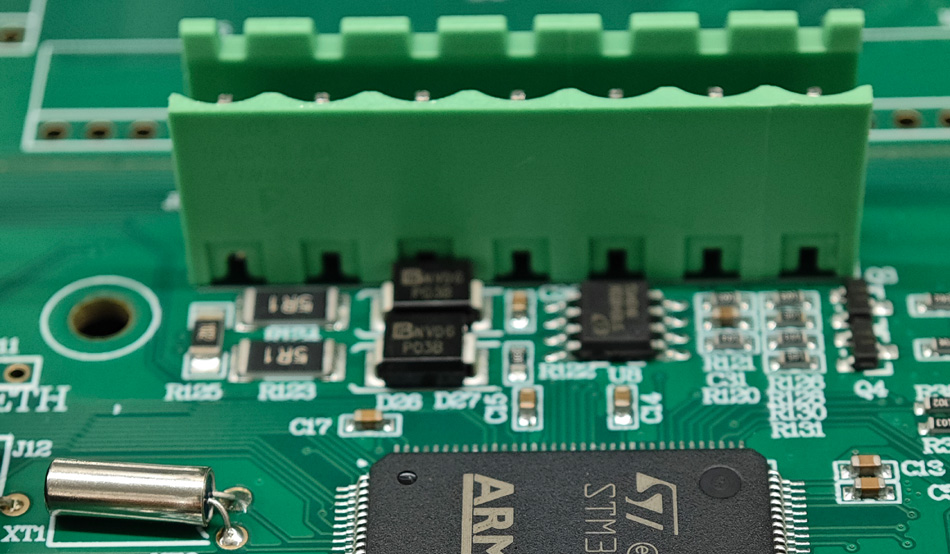

In today's highly competitive electronics manufacturing industry, PCBA (Printed Circuit Board Assembly) factories face increasing cost pressures. To ensure product quality while reducing production costs, more and more factories are adopting automated equipment. This article will explore how PCBA factories can effectively reduce costs through automation.

1. Types and Functions of Automated Equipment

SMT Placement Machines

Surface mount technology (SMT) placement machines are one of the most commonly used automated equipment in PCBA processing. They quickly and accurately place components on circuit boards, significantly improving production efficiency. Compared to manual placement, SMT placement machines not only reduce placement time but also reduce quality issues caused by human error.

Automated Test Equipment

Automated test equipment (ATE) monitors product quality in real time during the production process. By performing functional tests on each circuit board, factories can identify and correct problems promptly, reducing rework and scrap costs. This real-time monitoring helps improve product consistency and reliability.

2. Improving Production Efficiency

The accelerated pace of production

The introduction of automated equipment has made the production process more efficient. Automated equipment can operate 24/7, significantly shortening production cycles. Furthermore, the high-speed operation of the equipment significantly reduces the time required to complete each process, improving overall production efficiency.

Reduced Labor Requirements

With the introduction of automated equipment, factories are less reliant on manual labor. While the initial investment may be higher, reduced labor costs can significantly improve profitability in the long run. Furthermore, reduced labor costs reduce training and management costs associated with employee turnover.

3. Reduced Scrap and Rework Costs

Precise Placement and Soldering

Automated equipment significantly reduces scrap through high-precision placement and soldering technology. Compared to manual operations, machines ensure precise placement and soldering quality for each component, reducing rework and scrap losses caused by poor soldering.

Data-Driven Quality Management

Automated equipment is often equipped with data collection and analysis capabilities, recording various parameters during the production process in real time. This data can be used for quality analysis and improvement, enabling companies to adjust production processes in a timely manner, further reducing scrap.

4. Enhanced Flexibility and Adaptability

Quick Production Line Switchover

The flexibility of automated equipment enables production lines to quickly adapt to the demands of different products. By adjusting equipment settings, factories can quickly switch between different products, reducing the time and cost of reconfiguring production lines. This flexibility helps companies adapt to market changes and quickly respond to customer needs.

Support for Small Batch Production

In the modern market, small batches and diversified production models are becoming increasingly popular. Automated equipment can support small batch production, reducing inventory costs and capital tie-up, allowing factories to better meet customers' individual needs.

Conclusion

By introducing automated equipment, PCBA factories can reduce production costs in many ways. Whether it's improving production efficiency, reducing scrap rates, or enhancing production flexibility, automated equipment provides powerful support. In the increasingly competitive market, adopting an automation strategy not only effectively controls costs but also improves product quality, helping companies gain a competitive edge in the industry. Therefore, investing in automation equipment is a crucial step towards sustainable development for PCBA factories.

-

Delivery Service

-

Payment Options