- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Select the Ideal PCBA Supplier Based on the Comprehensive Capabilities of a PCBA Factory?

2025-09-08

In the rapidly evolving electronics industry, selecting an ideal PCBA (Printed Circuit Board Assembly) processing supplier is crucial for ensuring product quality and market competitiveness. A supplier's comprehensive capabilities encompass not only technical expertise, production capacity, and quality control systems, but also service levels, delivery capabilities, and customer communication and coordination skills. This article will explore how to select the right supplier by evaluating the comprehensive capabilities of a PCBA factory.

1. Technical Capabilities

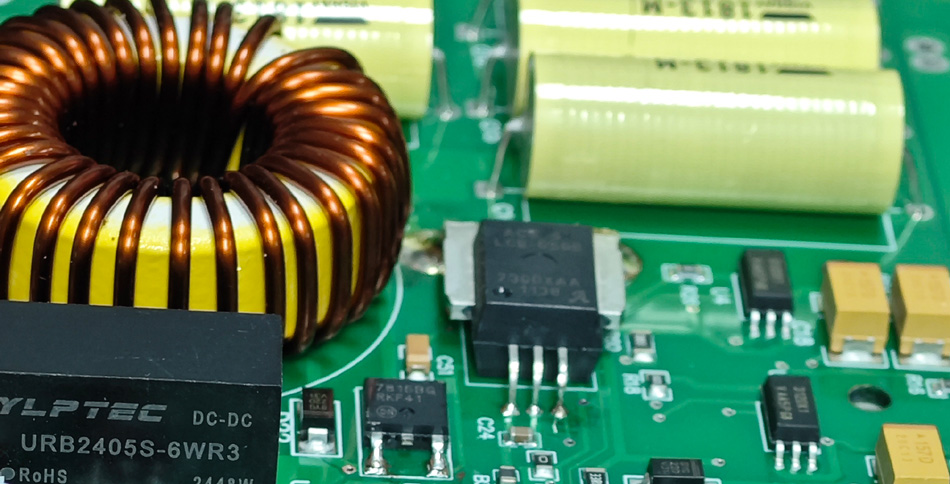

Equipment and Technical Level

The technical capabilities of PCBA processing are one of the most critical factors when selecting a supplier. You can assess whether a supplier's production equipment is modern and technologically mature by visiting the factory or reviewing its technical certifications (such as ISO 9001 and IPC-A-610). Furthermore, whether a factory has automated production lines and intelligent manufacturing capabilities also reflects its technical level. Suppliers with advanced technology generally provide higher-quality products and shorter delivery cycles.

Process and Experience

Understanding the supplier's process and experience is also a crucial evaluation indicator. A good PCBA factory should have extensive processing experience and be proficient in handling a variety of complex PCB design and assembly requirements. Reviewing a supplier's past success stories and customer feedback can help you determine their expertise in a specific industry or field.

2. Production Capacity

Capacity and Flexibility

Production capacity directly impacts delivery times and order flexibility. An ideal PCBA supplier should have stable production capacity and the ability to quickly adjust production plans based on market demand. Furthermore, whether the supplier can handle both large-volume orders and small-batch customizations is a key consideration. Suppliers with flexible production capabilities can better adapt to diverse customer needs.

Timely Delivery

Timely delivery is crucial to a company's supply chain management. When selecting a supplier, evaluate their delivery history to ensure they can deliver on time. Understanding their delivery reliability through communication with other customers can help mitigate production risks.

3. Quality Control

Quality Management System

A high-quality PCBA factory should have a comprehensive quality management system, encompassing incoming material inspection, process control, and final product testing. The supplier should have comprehensive quality control procedures to ensure that every step complies with industry standards. Reviewing their quality management system certifications (such as ISO 13485) and detailed quality control data can provide a strong basis for selecting a supplier.

After-Sales Service and Support

Excellent after-sales service is a key criterion for evaluating a supplier's overall capabilities. Selecting suppliers that provide timely technical support and solutions can help companies avoid unnecessary complications in future collaborations. Understanding their after-sales service policies and customer support capabilities ensures that any issues are resolved promptly.

4. Communication and Cooperation Skills

Communication Efficiency

The efficiency of communication between suppliers and customers directly impacts the smooth progress of collaboration. Selecting a PCBA factory that responds quickly to customer needs and demonstrates excellent communication skills can effectively avoid misunderstandings and delays caused by poor communication. During the inspection process, engaging in in-depth discussions with supplier personnel can help you understand the ease and effectiveness of their communication.

Cooperative Attitude

The supplier's cooperative attitude is also a key consideration in selection. A supplier that is cooperative and proactively responds to customer feedback is more likely to establish a strong long-term partnership. When selecting a supplier, you can assess their cooperative attitude by asking them about their understanding of customer needs.

Conclusion

Choosing the ideal PCBA supplier not only affects product quality and delivery but also impacts a company's overall supply chain management. By evaluating the supplier's technical capabilities, production capacity, quality control, and communication and cooperation capabilities, companies can make more scientific choices. A PCBA factory with strong comprehensive capabilities can not only meet the company's current needs, but also provide greater support and guarantees in future cooperation.

-

Delivery Service

-

Payment Options