- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Exploring Future PCBA Factory Development Trends: From Technology to Service

2025-09-06

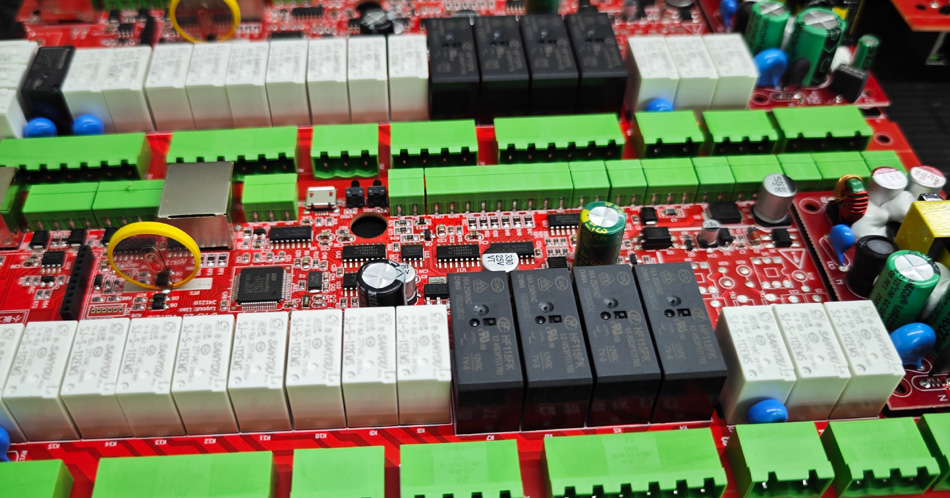

With the rapid development of the electronics industry, PCBA (Printed Circuit Board Assembly) processing, as a core component, is constantly evolving. Future PCBA factories will face numerous opportunities and challenges, from technological innovation to service upgrades. This article will explore the future development trends of PCBA factories, focusing on technology and service.

1. Technological Innovation Leads Change

Automation and Intelligent Manufacturing

Future PCBA factories will vigorously promote automation and intelligent manufacturing. The use of automated equipment can significantly improve production efficiency and product consistency, reducing human error. By introducing intelligent manufacturing systems, factories can not only achieve real-time monitoring and data analysis, but also dynamically adjust to market demand. For example, using Industrial Internet and Internet of Things (IoT) technologies, factories can achieve interoperability between equipment, optimize production processes, and improve overall efficiency.

New Materials and New Processes

With the increasing miniaturization and high performance of electronic products, the application of new materials and new processes will become a key trend in PCBA processing. For example, the widespread use of flexible printed circuits (FPCs) and high-frequency materials has driven continuous innovation in PCBA processes. Furthermore, the use of green and environmentally friendly materials will become a key development direction for factories, responding to the growing global emphasis on environmental protection.

Data-Driven Decision-Making

Big data analytics will play an increasingly important role in PCBA processing. By collecting and analyzing large amounts of data during the production process, factories can identify potential issues, optimize production processes, and improve product quality. This data-driven decision-making approach will help factories achieve more efficient resource allocation and cost control, thereby enhancing their market competitiveness.

2. Shift in Service Model

Customized Services

With the increasing diversification of customer needs, PCBA factories will increasingly prioritize customized services. By deeply understanding customers' specific needs, factories can provide tailored solutions, thereby enhancing customer satisfaction and loyalty. This customization extends beyond product design to encompass multiple aspects, including production processes, delivery cycles, and after-sales service.

Providing Value-Added Services

Beyond basic production services, PCBA factories will also shift towards value-added services. By offering services such as design consultation, sample production, fast delivery, and technical support, factories can create greater value for customers. Enhanced service capabilities will help factories stand out from the competition and win more customers.

Emphasizing Customer Relationship Management

Future PCBA factories will place greater emphasis on customer relationship management (CRM). By establishing a comprehensive customer information management system, factories can track customer needs, respond promptly to customer feedback, and enhance customer communication. This customer-centric service philosophy will foster long-term partnerships and increase customer satisfaction and loyalty.

3. Industry Collaboration and Ecosystem Building

Industry Chain Collaboration

Future PCBA factories will place greater emphasis on collaboration with upstream and downstream companies. By building an open industry ecosystem, factories can share resources and information with suppliers, customers, and partners, improving the efficiency of the entire industry chain. For example, establishing a collaborative platform that integrates design, procurement, production, and logistics will enable more efficient collaboration.

Sustainable Development

With growing environmental awareness, future PCBA factory development will place greater emphasis on sustainability. By optimizing production processes and material usage, reducing waste and energy consumption, factories can not only reduce costs but also fulfill their social responsibilities and enhance their brand image. Sustainable development will become a key competitive advantage for future PCBA factories.

Conclusion

Future PCBA factories will gain an advantage in the fiercely competitive market through technological innovation and service transformation. The advancement of automation and intelligent manufacturing, the application of new materials and processes, and the provision of customized and value-added services will drive the continued development of factories. Furthermore, establishing a sound industrial ecosystem and sustainable development strategies will help PCBA factories meet future challenges and achieve higher market value. By continuously adapting to industry changes, future PCBA factories will undoubtedly occupy a significant position in the global market.

-

Delivery Service

-

Payment Options