- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does the intelligent development of PCBA factories change the rules of the game?

2025-09-09

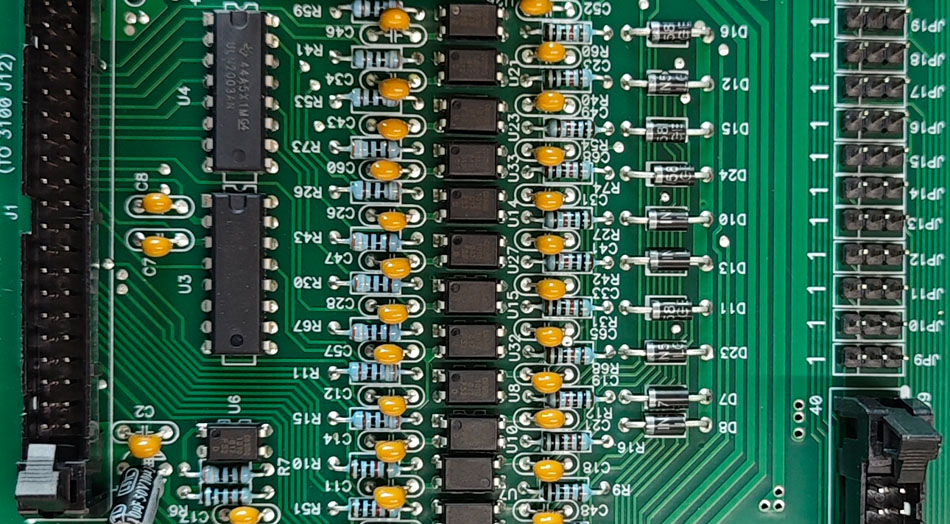

With the continuous advancement of technology, intelligentization has become a key trend in the transformation and upgrading of various industries. In the PCBA (Printed Circuit Board Assembly) processing industry, the development of intelligentization has not only improved production efficiency and product quality, but also changed the rules of the game. This article will explore how the intelligent development of PCBA factories is reshaping the industry ecosystem.

1. Improving Production Efficiency

Introduction of Automated Production Lines

Intelligent PCBA factories are typically equipped with advanced automated production lines. These lines utilize equipment such as robotic arms, automatic dispensing machines, and placement machines to achieve efficient production. This increased level of automation significantly improves production efficiency, enabling more orders to be completed in a shorter time. For example, the traditional manual PCBA processing process often takes several days, but the introduction of automated production lines can shorten this process to just a few hours.

Real-Time Data Monitoring and Analysis

Intelligent PCBA factories utilize IoT technology to enable real-time data monitoring and analysis. Factories can collect data from every step of the production process, promptly identifying potential problems and making adjustments. This real-time monitoring not only improves production efficiency but also reduces scrap rates, thereby reducing costs and improving overall economic benefits.

2. Ensuring Product Quality

Application of Intelligent Inspection Technology

The development of intelligent technology has significantly improved quality control in PCBA factories. By introducing intelligent inspection technologies such as machine vision systems and automated optical inspection (AOI), factories can conduct comprehensive product inspections. This inspection method is not only fast and accurate, but also allows for timely detection and elimination of defects during the production process, ensuring high product quality.

Improvements Driven by Big Data Analysis

Intelligent PCBA factories can also leverage big data analytics to continuously improve product quality. By analyzing historical data, factories can identify quality bottlenecks and key factors in production and optimize production processes. This data-driven decision-making ensures continuous improvement in product quality and enhances the company's market competitiveness.

3. Reducing Production Costs

Optimal Resource Allocation

Intelligent technology enables PCBA factories to more rationally allocate resources. Under traditional models, wasteful and inappropriate resource allocation often leads to increased production costs. Intelligent systems, however, allow factories to precisely calculate the raw materials, time, and labor required for production, thereby reducing waste and lowering production costs.

Intelligent Supply Chain Management

Intelligent PCBA factories also enable intelligent supply chain management. Through predictive analysis and inventory management systems, factories can better respond to market fluctuations. This efficient supply chain management reduces inventory costs, ensures production continuity and stability, and ultimately improves the company's economic benefits.

4. Changing the Industry's Competitive Landscape

The Rise of Emerging Competitors

The development of intelligent technology has not only transformed the operating models of traditional PCBA factories but also fueled the rise of emerging competitors. An increasing number of startups entering the market using intelligent technologies has put tremendous pressure on traditional companies. To remain competitive, traditional PCBA factories must undergo digital transformation and enhance their intelligence capabilities.

Quickly Responding to Customer Needs

Intelligent PCBA factories can respond to customer needs more quickly. Through flexible production arrangements and personalized services, factories can meet diverse customer needs. This enhanced capability not only increases customer satisfaction but also gives companies a competitive advantage.

Conclusion

The intelligent development of PCBA factories is profoundly changing the rules of the game in the industry. By improving production efficiency, ensuring product quality, reducing production costs, and transforming the competitive landscape, intelligent technology not only brings higher economic benefits to companies but also promotes overall industry upgrades. In the future, continuously promoting intelligent transformation will become the key for PCBA processing industry companies to win the market.

-

Delivery Service

-

Payment Options