- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can PCBA factories improve product competitiveness through innovation?

2025-09-03

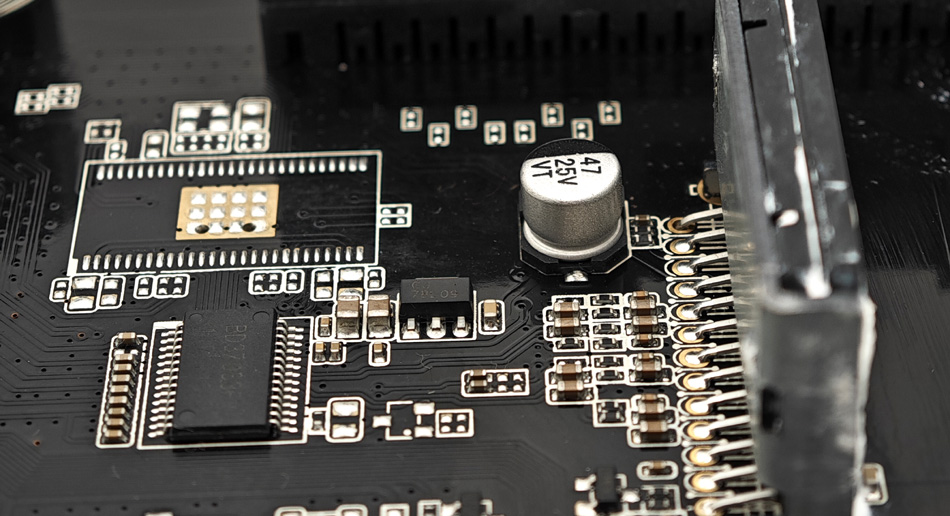

In the modern electronics manufacturing industry, PCBA (Printed Circuit Board Assembly) processing is not only a reflection of technology and craftsmanship, but also a crucial measure of a company's competitiveness. With the ever-changing market demands and rapid technological advancements, the innovation capabilities of PCBA factories have become a key factor in improving product competitiveness. This article will explore how to leverage the innovation capabilities of PCBA factories to enhance product market competitiveness.

1. Increase R&D Investment

Improve Technical Level

The core of PCBA processing lies in its technical level. Continuous R&D investment is the foundation for achieving technological breakthroughs and innovation. Factories should establish professional R&D teams dedicated to exploring and applying new materials and processes. For example, introducing more efficient welding techniques and environmentally friendly materials can significantly improve product quality while reducing environmental impact. Through technological innovation, companies can not only improve production efficiency, but also shorten time to market and enhance market responsiveness.

Developing Customized Solutions

In the fiercely competitive market, personalized needs are becoming increasingly prominent. PCBA factories can leverage the innovation of their R&D teams to develop customized solutions that meet specific customer needs. This personalized product not only meets customers' unique needs but also helps companies stand out from the competition and increase product added value.

2. Introducing Intelligent Production Technology

Application of Automated Equipment

Intelligent production is a key way to improve PCBA processing efficiency and product quality. By introducing automated equipment and robotics, factories can achieve high-precision and high-speed production. Intelligent production not only effectively reduces labor costs but also reduces human errors, improving product consistency and reliability. This efficient production method helps companies respond more quickly to market changes and enhance their competitive advantage.

Data-Driven Decision-Making

Modern PCBA factories can leverage big data analytics to monitor and optimize production processes in real time. Through data collection and analysis, factories can identify bottlenecks and problems in production and adjust production strategies in a timely manner. This data-driven decision-making not only improves production efficiency but also effectively reduces production costs, enabling companies to maintain a leading position in the fiercely competitive market.

3. Strengthening the Quality Management System

Comprehensive Quality Control

To enhance product competitiveness, PCBA factories must establish a comprehensive quality management system. By implementing international standards such as ISO9001, companies can systematically manage every aspect of the production process, from design and procurement to production and after-sales service, ensuring quality at every stage. High-quality products will directly enhance a company's reputation and brand image in the market.

Continuous Improvement and Feedback Mechanism

Companies should establish a continuous improvement mechanism to regularly evaluate and improve production processes and product quality. Furthermore, by collecting customer feedback on product usage and improvement suggestions, companies can continuously adjust and optimize product design and production processes. This customer-centric approach not only improves customer satisfaction but also enhances product market competitiveness.

4. Expanding Cooperation and Alliances

Collaborative Innovation within the Industrial Chain

PCBA factories can foster stronger synergies within the industrial chain through collaboration and alliances with upstream and downstream companies. Through collaboration, factories can share technology and resources with material suppliers, equipment manufacturers, and other organizations, driving innovation and development across the entire industrial chain. This collaborative innovation not only enhances the technological content of products but also creates advantages in cost control.

Expanding International Markets

Through technological innovation and collaboration, PCBA factories can also expand into the international market. In the context of globalization, companies need to continuously improve the international competitiveness of their products. By actively participating in international exhibitions and technical exchange events, factories can showcase their innovative capabilities, attract more international customers, and expand into new markets.

Conclusion

By leveraging the innovative capabilities of PCBA factories, companies can enhance product competitiveness while achieving sustainable development. Increasing R&D investment, introducing intelligent production technologies, strengthening quality management systems, and expanding partnerships and alliances are all effective ways to enhance product competitiveness. In the future, continuous innovation will be key to market success for companies in the PCBA processing industry.

-

Delivery Service

-

Payment Options