- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Analysis of Global PCBA Factory Collaboration Models: Challenges and Opportunities

2025-09-04

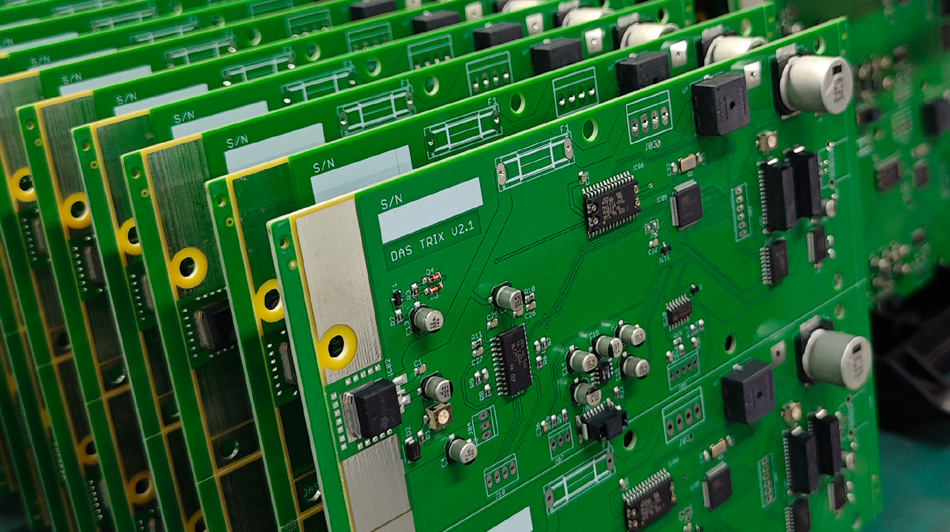

With the accelerating pace of globalization, the collaborative model within the PCBA (Printed Circuit Board Assembly) industry is undergoing profound changes. More and more companies are choosing to collaborate with overseas PCBA factories to reduce costs, improve production efficiency, and obtain technical support. However, this collaborative model presents both new opportunities and numerous challenges. This article will analyze the collaborative models of global PCBA factories and explore these challenges and opportunities.

1. The Evolution of Collaboration Models

From Single Supplier to Diversified Collaboration

In the past, many companies, when choosing PCBA processing, tended to focus solely on cost and delivery time, preferring a single supplier. However, with evolving market demands and technological advancements, more and more companies are realizing the importance of diversified collaboration. They are no longer relying solely on a single supplier, but are choosing to establish partnerships with multiple PCBA factories to reduce supply chain risks and increase product flexibility.

From Traditional Outsourcing to Strategic Collaboration

At the same time, the collaborative model is gradually shifting from traditional outsourcing to strategic collaboration. The relationship between companies and PCBA factories is becoming closer, transcending a buyer-seller relationship to achieve mutual development through technical exchange, R&D collaboration, and other means. This collaborative model can help companies better respond to market changes and enhance their competitiveness.

2. Challenges

Increased Quality Control Difficulties

Despite the many benefits of global collaboration, companies still face quality control challenges in PCBA processing. Differences in production standards, processes, and culture across regions can lead to inconsistent product quality, imposing additional costs and risks. Therefore, companies need to establish a strict quality control system to ensure that all partners meet consistent product quality standards.

Increased Communication and Coordination Costs

Global collaboration can also lead to increased communication and coordination costs. When working with PCBA factories in different regions, companies face multiple barriers, such as language, time zones, and culture, which can slow project progress. Therefore, companies need to establish efficient communication mechanisms to ensure timely and accurate information transfer.

Regulatory and Compliance Issues

International collaboration can also present challenges for companies due to the varying regulations and compliance requirements of different countries. PCBA processing involves multiple regulations, including environmental protection, quality, and safety. Companies need to ensure that their partners comply with these laws and regulations to avoid potential legal risks.

3. Opportunities and Prospects

Cost Advantages

Despite challenges, the global PCBA factory collaboration model still offers significant cost advantages for companies. By selecting regions with lower labor costs for production, companies can significantly reduce production costs and improve market competitiveness. Furthermore, by leveraging the resources and technological advantages of different regions, companies can achieve higher production efficiency.

Technological Innovation and Sharing

Global collaboration also presents opportunities for technological innovation. By collaborating with internationally renowned PCBA factories, companies can acquire advanced production technologies and management experience, enhancing their own technical capabilities. Furthermore, through joint R&D and technical exchanges, companies can promote new product development and strengthen their market competitiveness.

Market Expansion

Through collaboration with global PCBA factories, companies can more easily expand into international markets. Collaborating with local PCBA factories not only shortens delivery times but also strengthens customer trust and helps increase product acceptance in the international market. This market expansion strategy offers companies greater potential for growth.

Conclusion

The global PCBA factory collaboration model is constantly evolving. While facing challenges such as quality control, communication and coordination, and regulatory compliance, it also offers companies significant cost advantages, technological innovation, and market expansion opportunities. When choosing a PCBA processing partner, companies should comprehensively consider these factors and establish effective cooperation mechanisms to achieve win-win results and promote their own sustainable development. In an increasingly competitive market environment, flexibly responding to challenges and seizing opportunities will be the key to companies' success in the PCBA industry.

-

Delivery Service

-

Payment Options