- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Evaluating the Comprehensive Capabilities of PCBA Factories from a Technical Perspective

2025-09-02

In today's rapidly developing electronics manufacturing industry, PCBA (Printed Circuit Board Assembly) processing has become a key focus for many companies seeking outsourcing partnerships. However, selecting the right PCBA factory is not an easy task, especially when evaluating its comprehensive capabilities from a technical perspective. This article will explore several technical factors that should be considered when evaluating a PCBA factory's comprehensive capabilities.

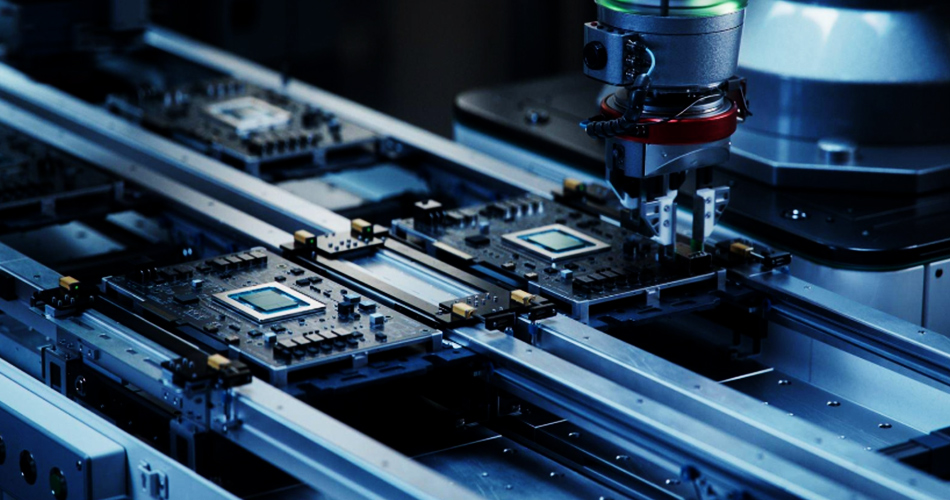

1. Production Equipment and Technology Level

Modern Equipment

First, evaluating a PCBA factory's production equipment is key to understanding its technical capabilities. Efficient, modern production equipment can significantly improve production efficiency and product quality. For example, advanced SMT (Surface Mount Technology) placement machines can achieve higher placement accuracy and speed. Furthermore, the level of automation in the equipment directly impacts the flexibility and stability of the production line.

Process Technology

Secondly, the advancement of process technology is equally crucial. PCBA factories need to master a variety of soldering processes, such as wave soldering, reflow soldering, and hand soldering. By flexibly applying these different processes, factories can provide customized production solutions tailored to specific customer needs, enhancing their market competitiveness.

2. Quality Control System

Strict Quality Standards

The quality of PCBA processing directly impacts the performance and reliability of the final product. Therefore, evaluating the factory's quality control system is particularly important. A high-quality PCBA factory should be certified by international quality management systems such as ISO 9001 and strictly adhere to relevant standards. By implementing strict quality control, the factory can promptly identify and correct problems during the production process, ensuring consistent product quality.

Testing Equipment and Capabilities

Testing equipment and capabilities are also important indicators for evaluating a factory's overall capabilities. PCBA factories need to be equipped with advanced testing equipment, such as automated optical inspection (AOI) equipment, X-ray inspection equipment, and functional testing equipment, to ensure that every batch of products meets customer requirements. Comprehensive testing capabilities can significantly reduce product return rates and improve customer satisfaction.

3. Technical Team and Experience

Professional Technical Team

The professionalism and experience of the technical team directly impact the overall capabilities of a PCBA factory. When evaluating a factory, pay attention to the qualifications and experience of its technical team, including the engineers' academic qualifications, work experience, and professional background. A highly experienced team can effectively resolve technical issues encountered during production, ensuring smooth production.

Continuous Training and R&D

Also, it's crucial for the factory to prioritize employee training and technological R&D. A high-quality PCBA factory regularly organizes employee training to enhance their skills and actively pursues process improvements and new technology development to adapt to market changes and customer needs.

4. Customer Service and Support

Comprehensive Customer Support

Finally, customer service is a crucial aspect of evaluating a PCBA factory's overall capabilities. A high-quality PCBA factory should be able to quickly respond to customer needs and provide comprehensive technical support and after-sales service. Maintaining good communication with customers during technical exchanges, project implementation, and problem-solving directly impacts the success of the collaboration.

Flexible Collaboration Model

Furthermore, a PCBA factory's collaboration model must be flexible to meet the needs of diverse customers. Whether it's small-batch customization or large-scale production, the factory should be able to provide appropriate solutions to ensure the smooth progress of customer projects.

Conclusion

Evaluating a PCBA factory's comprehensive capabilities from a technical perspective requires consideration of multiple aspects, including production equipment and technology, quality control systems, technical team and experience, and customer service and support. This comprehensive assessment allows companies to select the right PCBA partner and ensure the success of their projects. In an increasingly competitive market, selecting a technically strong PCBA factory will lay a solid foundation for a company's long-term development.

-

Delivery Service

-

Payment Options