- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can innovative technologies at PCBA factories reduce project risks?

2025-09-01

Project risk management is crucial in the electronics manufacturing industry, especially in the field of PCBA (Printed Circuit Board Assembly) fabrication. With intensifying market competition and diversifying customer demands, companies must seek effective methods to mitigate project risks. Introducing innovative technologies can not only improve production efficiency but also significantly reduce project risks. This article will explore how innovative technologies at PCBA factories can achieve this goal.

1. Advanced Design Tools

Using EDA Software

The use of electronic design automation (EDA) software during the PCBA process can significantly reduce the risk of design errors. Modern EDA tools not only help engineers design circuits more efficiently but also identify potential issues promptly through simulation and design verification. This early intervention avoids subsequent revisions due to design flaws and reduces overall project risk.

Design for Manufacturability (DFM)

By implementing Design for Manufacturability (DFM) principles, PCBA factories can ensure that designs are feasible during production. DFM tools consider manufacturing constraints and requirements during the design phase, mitigating the risks associated with design-to-production mismatches. This innovative technology enables engineers to foresee and resolve potential production issues during the design phase.

2. Automated Production Processes

Introducing Intelligent Equipment

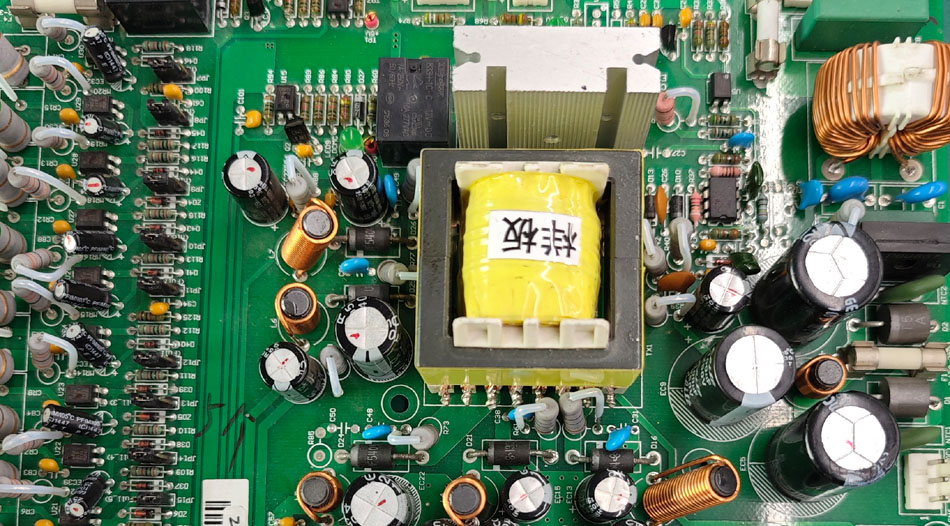

Introducing automated production equipment in PCBA factories can significantly improve production accuracy and reduce the risk of human error. Automated equipment enables efficient and precise operation during the production process, reducing quality issues caused by improper manual operation. This innovative technology not only improves production efficiency but also reduces the risk of rework and product returns due to product quality issues.

Real-time Monitoring System

By installing a real-time monitoring system, PCBA factories can track equipment status and product quality in real time during the production process. This system can promptly identify and correct production issues, reducing production risks. For example, the monitoring system can promptly detect products with substandard soldering quality, preventing these defective products from entering the market.

3. Data Analysis and Prediction

Big Data Technology

Data analysis and big data technologies are increasingly being used in modern PCBA manufacturing. By analyzing data from the production process, factories can identify potential production bottlenecks and quality issues. This data-driven decision-making process enables managers to take timely action and mitigate project risks.

Predictive Maintenance

Using data analytics, PCBA factories can implement predictive maintenance. By monitoring and analyzing equipment operating status, factories can perform maintenance before equipment failures occur, thus avoiding production interruptions caused by equipment failures. This innovative technology effectively reduces the risk of equipment downtime and improves production continuity and stability.

4. Flexible Production Capabilities

Customized Production

As customer demands fluctuate, PCBA factories need flexible production capabilities. By adopting flexible production technologies, factories can quickly respond to changes in customer needs and implement small-batch, high-variety production models. This flexibility not only reduces inventory risks but also meets market demand for rapid new product launches.

Rapid Response Mechanism

Innovative technologies also enable PCBA factories to establish rapid response mechanisms. Through intelligent manufacturing systems, factories can quickly respond to market changes and adjust production plans in a timely manner. This rapid response capability reduces project risks caused by market demand fluctuations and improves customer satisfaction.

Conclusion

In the PCBA processing industry, the introduction of innovative technologies can effectively reduce project risks. From advanced design tools to automated production processes to data analysis and forecasting, innovative technologies provide new solutions for project management. As the market continues to develop, PCBA factories should continue to explore and implement innovative technologies to improve their competitiveness and market adaptability to ensure the smooth progress of projects.

-

Delivery Service

-

Payment Options