- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

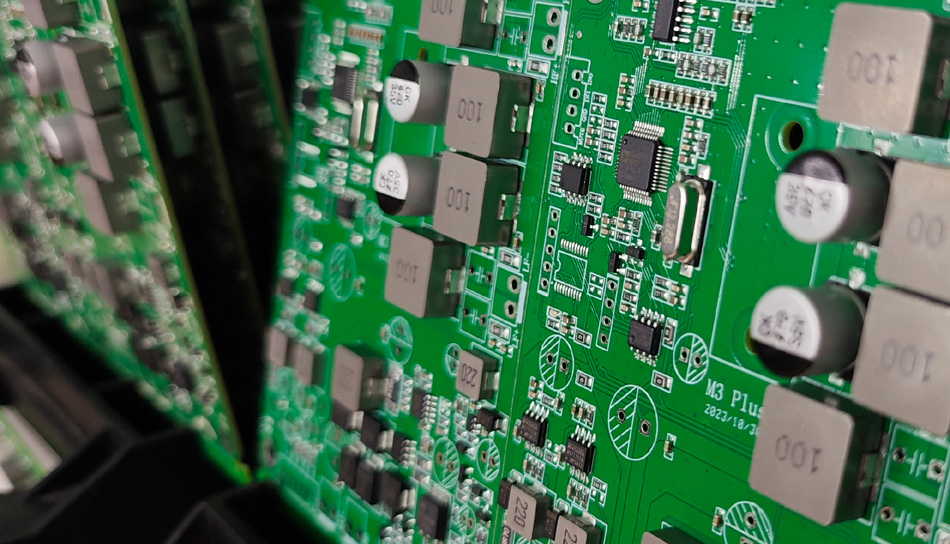

From Production Planning to Final Delivery: Process Optimization Strategies for PCBA Factories

In today's highly competitive electronics manufacturing industry, the efficiency and quality of PCBA (Printed Circuit Board Assembly) processing directly impacts a company's market competitiveness. To achieve efficient operations within complex production processes, PCBA factories must implement a series of process optimization strategies to ensure smooth and efficient operations at every stage, from production planning to final delivery. This article will explore process optimization strategies for PCBA factories in each stage.

1. Accurate Production Planning

Demand Forecasting and Production Planning

The first step in production planning is an accurate demand forecast. By analyzing market trends, customer needs, and historical order data, PCBA factories can develop a reasonable production plan to ensure sufficient supply of raw materials and human resources. Accurate demand forecasts are directly related to smooth production and avoid overproduction and waste of resources.

Bill of Materials Management

Material management is crucial in the PCBA process. Factories need to establish a detailed bill of materials, clearly defining the components and materials required for each production step. By implementing Material Requirements Planning (MRP), factories can monitor materials in real time to ensure that there are no shortages during the production process.

2. Standardization of Production Processes

Establishing Standard Operating Procedures (SOPs)

To improve production efficiency, PCBA factories should establish standard operating procedures (SOPs) to ensure that every employee follows established operating specifications. Standardized operations can reduce human error, improve production consistency, and reduce the time and cost of training new employees.

Visual Process Management

Introducing visual management tools can help employees more intuitively understand production processes and task progress. By setting up visual dashboards, factories can display production status, material inventory, and equipment operation in real time, thereby strengthening employee responsibility and increasing production enthusiasm.

3. Intelligent Equipment and Technology

Introduction of Automated Equipment

The application of automation technology is an effective way to improve PCBA processing efficiency. By introducing automated equipment, factories can achieve high-speed and high-precision production, reducing the instability caused by human intervention. Furthermore, automated equipment can reduce labor intensity and improve employee efficiency.

Data-Driven Production Decision-Making

The key to intelligent manufacturing lies in data collection and analysis. By implementing Industrial Internet technologies, PCBA factories can obtain real-time production data, conduct in-depth analysis, identify production bottlenecks, and optimize resource allocation. Data-driven decision-making can effectively improve production efficiency and enable quick response when problems arise.

4. Comprehensive Quality Control

Establishing a Quality Management System

Quality control is an essential component of the PCBA manufacturing process. Factories should establish a comprehensive quality management system, implementing rigorous quality inspections from raw material intake, through the production process, to final product shipment. This not only reduces defect rates but also improves customer satisfaction.

Continuous Improvement Mechanism

Establishing a continuous improvement mechanism promotes continuous improvement in quality management through regular quality audits and employee training. Leveraging customer feedback and market data, timely adjustments to production processes ensure consistently high product quality.

5. Overall Delivery Efficiency

Implementing Lean Manufacturing

Lean manufacturing is a management philosophy that prioritizes efficiency and value. By identifying and eliminating non-value-added steps in the production process, PCBA factories can improve overall delivery efficiency. The key to implementing lean manufacturing lies in continuously optimizing processes, enhancing team collaboration, and achieving rapid delivery.

Optimizing Supply Chain Management

Effective supply chain management can improve a PCBA factory's responsiveness and delivery capabilities. By establishing close partnerships with suppliers, factories can ensure timely supply of raw materials, reduce inventory costs, and improve overall operational efficiency.

Conclusion

Process optimization strategies for PCBA factories are key to achieving efficient production and high-quality delivery. From precise production planning and standardized operating procedures to the use of intelligent equipment and comprehensive quality control, factories must continuously optimize every aspect to improve overall efficiency. By implementing these process optimization strategies, PCBA factories can remain competitive in the fierce market and meet customers' ever-changing needs.

Send Inquiry

-

Delivery Service

-

Payment Options