- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Achieve Fast Delivery Through Efficient Production Management in PCBA Factories

In today's fiercely competitive electronics market, fast delivery has become a key competitive advantage for PCBA (Printed Circuit Board Assembly) manufacturers. Achieving fast delivery through efficient production management is a pressing issue for many PCBA manufacturers. This article explores ways to improve PCBA processing efficiency and achieve fast delivery through optimizing production processes, strengthening supply chain management, and applying intelligent manufacturing technologies.

1. Optimizing Production Processes

Applying Lean Manufacturing Concepts

Adopting lean manufacturing concepts is an effective way to improve PCBA processing efficiency. By identifying and eliminating waste in the production process, factories can significantly improve production efficiency. Specific measures include rationalizing production line layout, reducing unnecessary handling and waiting time, and optimizing process design. These measures not only shorten production cycles but also improve product quality and reduce costs.

Developing a Scientific Production Plan

A scientific production plan is the foundation for ensuring fast delivery. PCBA factories should develop reasonable production plans based on customer needs and market changes to ensure efficient allocation of production resources. By using production management software, factories can monitor production progress in real time and adjust production plans promptly to address unexpected order changes. This flexible production planning management helps improve delivery reliability.

2. Strengthen Supply Chain Management

Establish a Stable Supply Chain System

In PCBA processing, the timely supply of raw materials is crucial for fast delivery. Factories should establish long-term partnerships with stable suppliers to ensure the timely delivery of raw materials. At the same time, they can consider diversifying their supply chain to avoid production schedules being impacted by the mistakes of a single supplier.

Implementing Collaborative Supply Chain Management

To improve the responsiveness of the entire supply chain, PCBA factories need to collaborate with upstream and downstream companies. Through information sharing and communication, factories can better predict market demand and optimize production plans. Suppliers can also adjust delivery cycles based on production needs to ensure timely delivery. This collaborative management will significantly improve delivery efficiency.

3. Applying Intelligent Manufacturing Technologies

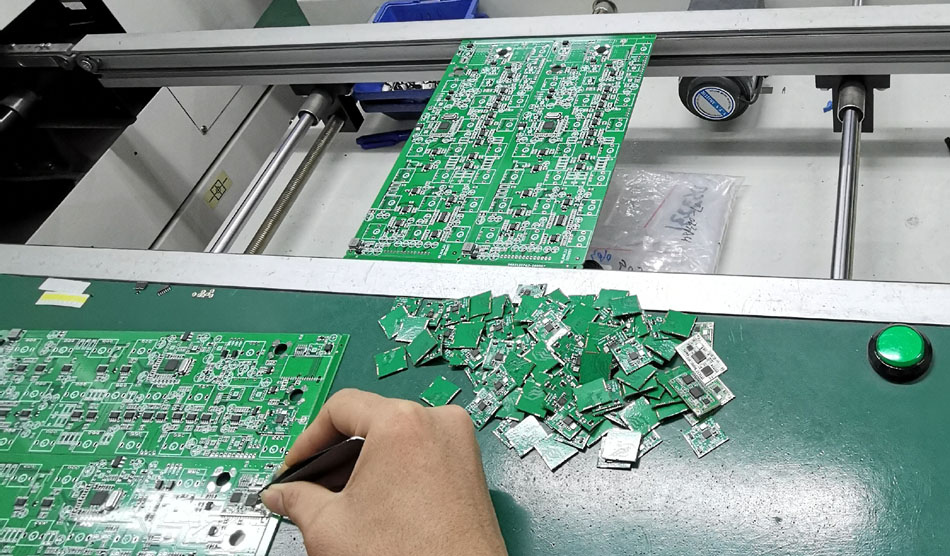

Introducing Automated Equipment

The application of automated equipment can significantly improve production efficiency in PCBA processing. By introducing equipment such as robots and automated production lines, factories can reduce manual intervention and increase production speed and precision. For example, automated welding and testing equipment can achieve fast and accurate production, reducing the incidence of human error.

Application of Big Data and Artificial Intelligence

The combination of big data and artificial intelligence technologies can help PCBA factories achieve intelligent management. By analyzing production data, factories can promptly identify production bottlenecks and optimize production processes. Furthermore, intelligent algorithms can predict equipment failures and pre-schedule maintenance, reducing downtime and improving production continuity. These measures all contribute to improved delivery efficiency and reliability.

4. Strengthening Quality Control

Implementing Total Quality Management

While pursuing rapid delivery, PCBA factories cannot neglect product quality. Implementing Total Quality Management (TQM) ensures that products meet quality standards throughout every stage of production. Through continuous quality improvement, factories can reduce defect rates, thereby reducing rework and re-inspection time and improving delivery efficiency.

Introducing Intelligent Quality Inspection Systems

Intelligent quality inspection systems monitor product quality in real time during the production process, promptly identifying and correcting quality issues. This rapid feedback mechanism not only ensures product quality but also effectively shortens production cycles, enabling faster delivery.

Conclusion

By optimizing production processes, strengthening supply chain management, applying intelligent manufacturing technologies, and strengthening quality control, PCBA factories can achieve efficient production management and ensure rapid delivery. This not only meets customer expectations for delivery speed but also enhances the factory's market competitiveness. In the future market, fast delivery will become a key factor for PCBA processing companies to win customer trust and loyalty.

Send Inquiry

-

Delivery Service

-

Payment Options