- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can equipment upgrades in PCBA factories improve product quality?

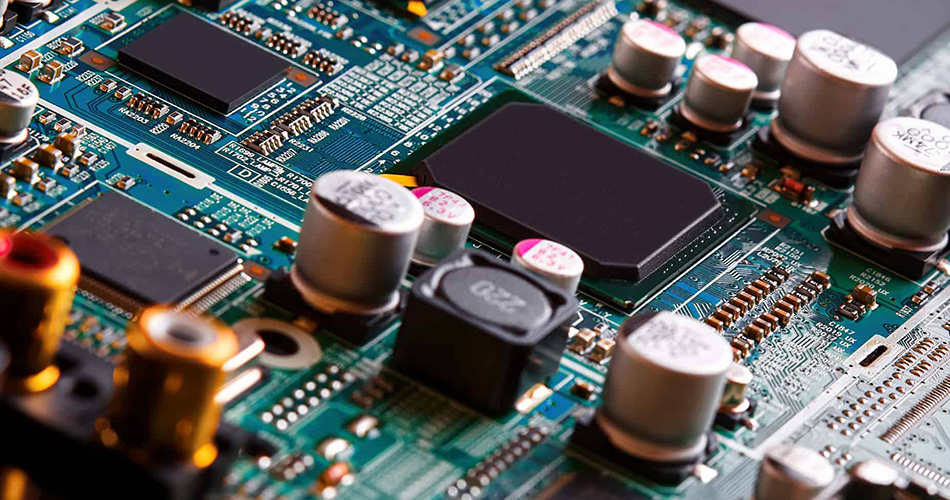

In the rapidly evolving electronics industry, the quality of PCBA (Printed Circuit Board Assembly) processing directly impacts product performance and reliability. With technological advancements, equipment upgrades have become a crucial means of improving product quality. This article will explore how to achieve this through equipment upgrades in PCBA factories.

1. Understanding the Necessity of Equipment Upgrades

With ever-changing market demands and rapidly evolving technologies, older equipment often cannot meet the requirements of modern PCBA processing. Equipment upgrades not only increase production efficiency but also significantly improve product quality. Newer equipment often features more advanced technologies and functions, enabling more precise completion of complex processing tasks and reducing defects during the production process.

2. Selecting the Right Equipment

Introducing Automated Equipment

Introducing automated equipment in the PCBA process is key to improving product quality. Automated equipment, such as placement machines, wave soldering machines, and functional testing equipment, not only increases production speed but also ensures consistency throughout each process. For example, automated placement machines precisely position and attach components, reducing human error and thus improving soldering quality.

Precision Inspection Equipment

Equipment upgrades should also include updating inspection equipment. Introducing high-precision inspection equipment, such as online optical inspection (AOI), X-ray inspection (AXI), and functional testing equipment, allows for real-time monitoring of product quality during the production process. By quickly identifying defects, factories can adjust production parameters promptly, reduce defect rates, and improve overall product quality.

3. Improving Process Levels

Improving Soldering Processes

Soldering is a crucial step in PCBA processing. Equipment upgrades can introduce more advanced soldering technologies, such as laser soldering or selective soldering, which effectively improve solder uniformity and strength, reducing solder joint defects. Furthermore, improved soldering processes can reduce the thermal impact on components during soldering, extending product lifespan.

Optimizing Production Processes

Equipment upgrades involve more than just hardware updates; they should also incorporate optimization of production processes. By implementing intelligent manufacturing systems, PCBA factories can automate and inform their production processes, thereby improving production efficiency and product consistency. For example, by monitoring production progress in real time, managers can adjust production plans based on actual conditions, ensuring consistent product quality.

4. Employee Training and Equipment Maintenance

Improving Employee Skills

After upgrading equipment, employees need appropriate training to master the operation and maintenance of the new equipment. Regular skills training can improve employee proficiency with the new equipment, thereby reducing operational errors and improving production efficiency and product quality.

Regular Equipment Maintenance

Stable equipment operation is the foundation for ensuring product quality. PCBA factories should establish an equipment maintenance system and regularly inspect and maintain equipment to ensure it operates in optimal condition. Timely maintenance can prevent equipment failures and reduce production downtime and quality degradation caused by equipment problems.

5. Data-Driven Quality Management

Collecting and Analyzing Quality Data

Upgrading equipment makes it easier for PCBA factories to collect and analyze quality data from the production process. This data provides a reliable basis for quality management. By analyzing this data, factories can identify potential quality issues and take timely measures to improve product quality.

Real-Time Feedback and Adjustment

Modern equipment often features real-time monitoring capabilities, providing timely feedback on production process data. This real-time feedback allows managers to quickly understand production status and make adjustments as necessary to ensure consistent product quality standards.

Conclusion

Equipment upgrades are a crucial path to improving PCBA product quality. By introducing advanced automation and testing equipment, optimizing soldering processes, enhancing employee skills, and establishing a data-driven quality management system, PCBA factories can effectively improve product quality and enhance their market competitiveness. In an increasingly competitive market, only by continuously upgrading equipment and improving processes can we meet customer needs and maintain sustainable business growth.

Send Inquiry

-

Delivery Service

-

Payment Options