- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why is it wise to choose a PCBA factory with advanced management systems?

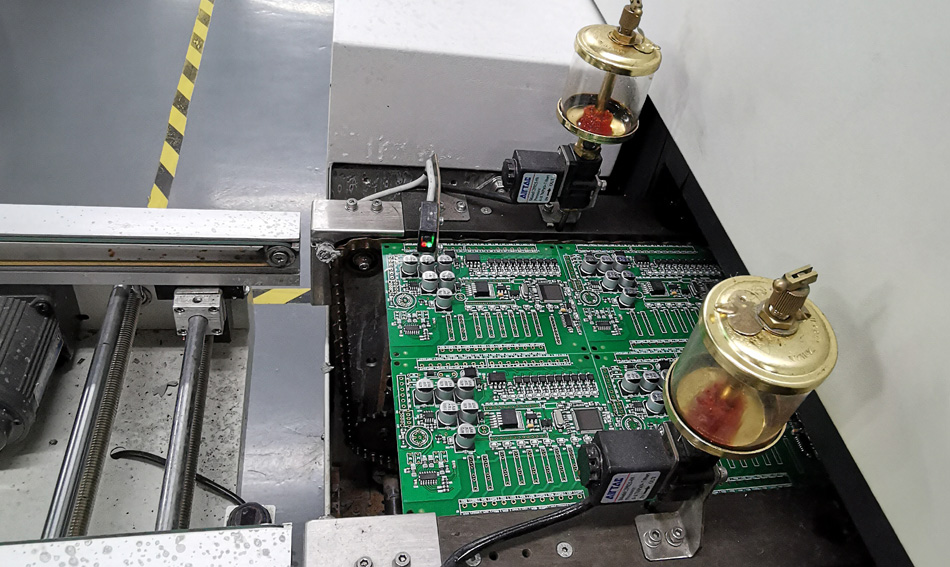

PCBA (Printed Circuit Board Assembly) processing is a crucial step in the electronics manufacturing industry. Choosing a PCBA factory with advanced management systems not only improves product quality but also effectively reduces production costs and increases delivery efficiency. This article will explore why choosing a PCBA factory with advanced management systems is a wise choice and analyze the multiple advantages it offers.

1. Improving Production Efficiency

Process Optimization and Standardization

PCBA factories with advanced management systems typically conduct in-depth analysis and optimization of their production processes and adopt standardized operating procedures. This management system not only improves production efficiency but also ensures the smooth flow of each link, reducing production delays caused by process inaccuracies. Furthermore, standardization allows workers to familiarize themselves with their work more quickly, reducing training time.

Real-Time Data Monitoring and Feedback

Modern PCBA factories are often equipped with advanced production management systems that enable real-time data monitoring of the production process. This monitoring provides timely feedback on production status, enabling management to make quick decisions and avoiding resource waste caused by information lags. All of this helps ensure efficient production.

2. Ensure Product Quality

A Comprehensive Quality Management System

Choosing a PCBA factory with an advanced management system generally means its quality management system is more comprehensive. By implementing methods such as Total Quality Management (TQM) and Six Sigma, the factory can strictly control quality during the production process, ensuring that every product meets customer requirements.

Advanced Testing Equipment and Technology

Modern PCBA factories invest heavily in advanced testing equipment and technology. These devices not only improve testing accuracy but also enable automated testing, reducing the possibility of human error. This quality assurance mechanism effectively enhances customer confidence in the product.

3. Reduce Production Costs

Lean Management and Resource Optimization

PCBA factories with advanced management systems typically adopt lean production management concepts and focus on optimizing resource allocation. By identifying and eliminating waste in production, the factory can reduce production costs while ensuring quality. This cost advantage not only enhances the company's competitiveness but also provides customers with more cost-effective products.

Efficient Supply Chain Management

Advanced PCBA factories often have more efficient supply chain management capabilities. This includes close collaboration with suppliers and precise inventory management. By optimizing the supply chain, factories can reduce raw material procurement costs, improve overall operational efficiency, and ultimately lower production costs.

4. Improve Customer Satisfaction

Timely Delivery

In the fiercely competitive market, customers are increasingly demanding faster delivery. Selecting a PCBA factory with advanced management systems can ensure improved production efficiency and achieve faster delivery. Rapid response to customer needs not only increases customer satisfaction but also strengthens customer loyalty.

Attention to Customer Feedback

PCBA factories with advanced management systems prioritize customer feedback and conduct regular customer satisfaction surveys. This customer-centric management philosophy helps factories continuously improve their products and services to meet customers' evolving needs.

Conclusion

Choosing a PCBA factory with advanced management systems is a wise move. By improving production efficiency, ensuring product quality, reducing production costs, and enhancing customer satisfaction, factories can remain competitive in a highly competitive market. As the electronics industry continues to evolve, choosing an excellent partner will lay a solid foundation for your company's long-term growth.

Send Inquiry

-

Delivery Service

-

Payment Options