- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

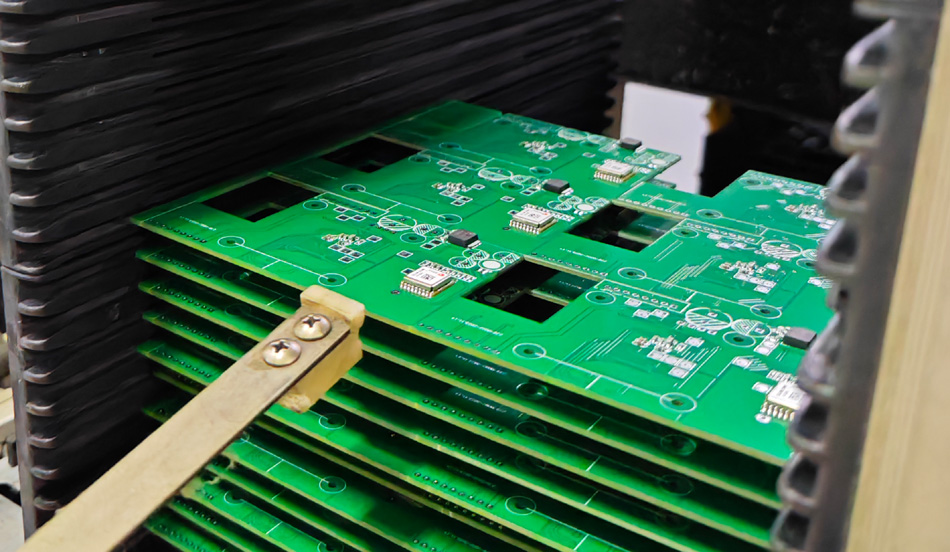

The Impact of Automation Levels in PCBA Factories on Mass Production

With the rapid development of the electronics market, demand for PCBA (Printed Circuit Board Assembly) processing is also increasing. To meet market demands for high quality and efficiency, many PCBA factories are moving towards automation. This article will explore how the automation level of PCBA factories affects mass production, thereby improving production efficiency, reducing costs, and enhancing product quality.

1. The Relationship between Automation Level and Production Efficiency

Increasing Production Speed

The introduction of automated equipment has significantly increased the speed of PCBA processing. By using automatic placement machines, soldering robots, and inspection equipment, factories can complete large production volumes in a shorter time. For example, automatic placement machines can accurately place electronic components on PCBs in a very short time, significantly shortening production cycle times.

Reducing Manual Intervention

In traditional production models, manual operations are often a bottleneck. Through automated production, factories can reduce manual intervention and lower the incidence of human error. For example, automated inspection systems can monitor the production process in real time, promptly detecting and correcting defects, thereby ensuring continuous and consistent production.

2. Cost Control and Automation

Reducing Labor Costs

Although the initial investment in automated equipment is high, it can significantly reduce labor costs in the long run. With increased automation, companies can reduce their reliance on manual labor while maintaining the same production scale. By managing more production lines with fewer employees, factories can effectively reduce operating costs.

Optimizing Resource Allocation

Automation can also optimize resource allocation. For example, through intelligent production scheduling systems, factories can rationally schedule production based on order demand, reducing raw material waste. This efficient use of resources makes the production process more economical and improves overall production efficiency.

3. Improving Product Quality

Improving Consistency and Stability

In PCBA processing, product quality stability is crucial. The use of automated equipment ensures stable process parameters at every stage, thereby improving product consistency. Automated production lines enable precise component placement and soldering, effectively reducing quality fluctuations caused by human factors.

Real-Time Monitoring and Feedback

The real-time monitoring function of the automation system allows factories to obtain timely data on the production process and provide rapid feedback on production status. When the system detects an anomaly, it can immediately adjust production parameters to avoid defective products and ensure high final product quality.

4. Flexible Response to Market Demand

Strong Adaptability

Modern market demand for PCBA products fluctuates rapidly. The flexibility of automated production lines enables factories to quickly adjust production strategies. Whether operating in small, diversified batches or in large, centralized production, automated systems can respond promptly to market demands.

Shortening Delivery Cycles

By improving production flexibility and efficiency, PCBA factories can shorten delivery cycles. With customer demands constantly changing, rapid response and flexible adjustments to production plans are crucial for companies' competitiveness.

Conclusion

In summary, the level of automation in PCBA factories has a profound impact on high-volume production. By increasing production efficiency, reducing costs, improving product quality, and enhancing market adaptability, automation is not only a key driver of the PCBA processing industry's development but also a key factor in helping companies stand out in the fiercely competitive market. Therefore, PCBA factories should actively invest in automation equipment and technologies and continuously improve their automation levels to achieve sustainable development.

Send Inquiry

-

Delivery Service

-

Payment Options