- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

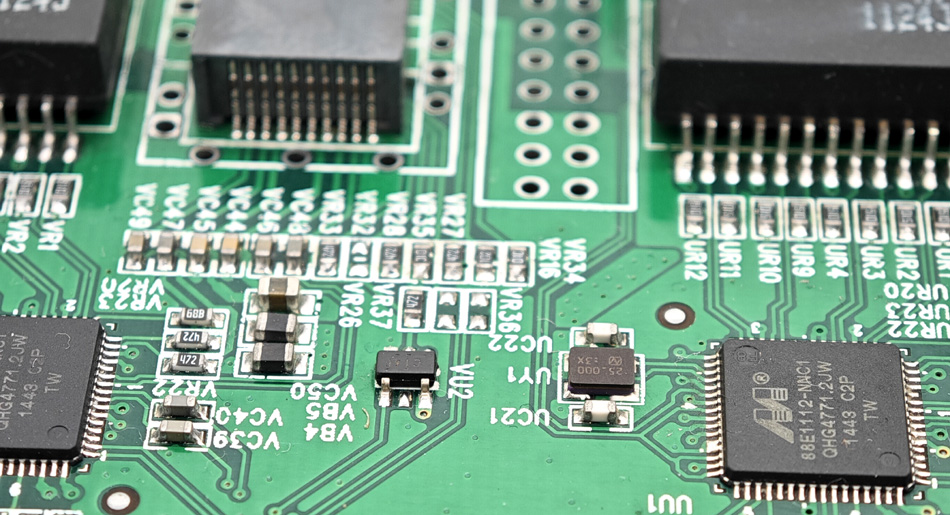

How do PCBA factories meet the production challenges of customized orders?

In today's rapidly evolving electronics industry, demand for customized orders is increasing. Customers' demands for product personalization, flexibility, and fast delivery pose a series of production challenges for PCBA (Printed Circuit Board Assembly) factories. This article will explore how PCBA factories can address these challenges and ensure efficient production for customized orders.

1. Understanding Customer Needs

Conducting an In-Depth Needs Analysis

For customized orders, PCBA factories must first conduct in-depth discussions with customers to understand their specific needs. This includes information such as product specifications, functional requirements, quantity, and delivery time. This comprehensive needs analysis allows factories to develop a production plan that meets customer expectations.

Flexibly Adjusting Production Plans

After understanding customer needs, factories must be able to flexibly adjust production plans. Customized orders often involve multiple products with varying specifications. Factories must be able to quickly respond to changes and rationally allocate production resources to ensure timely delivery.

2. Optimizing Production Processes

Implementing Modular Design

To better handle customized orders, PCBA factories can adopt a modular design approach. By designing products as standardized modules, production efficiency can be improved. Different products can share the same modules, reducing production line changeover time.

Adopting Flexible Production Line Configurations

Flexible production line configurations help PCBA factories quickly adapt to changing production needs. Factories can adjust equipment layouts and optimize process scheduling based on order characteristics to improve production efficiency. Flexible production line configurations can effectively meet the production requirements of high-mix, small-batch products.

3. Strengthening Technical Capabilities

Introducing Automated Equipment

For customized orders, introducing automated equipment can significantly improve production efficiency and product quality. Automated equipment enables high-precision production and reduces human error. The advantages of automated production are particularly evident when handling complex customized products.

Improving Employee Skills

To better meet the challenges of customized orders, PCBA factories must also focus on improving employee skills. Regular training should be conducted to familiarize employees with new technologies, equipment operation, and the production processes for customized products, ensuring smooth production.

4. Strengthening Supply Chain Management

Optimizing Material Management

Customized orders often require specialized raw materials and components, making optimized material management crucial. PCBA factories should establish good partnerships with suppliers to ensure the timely supply of raw materials. At the same time, on-demand procurement can be adopted to reduce inventory costs.

Improve Communication Efficiency

In customized production, communication efficiency with all links in the supply chain directly impacts production progress. PCBA factories can leverage information technology to establish an efficient information sharing platform to ensure coordination and collaboration across all production links, thereby improving overall production efficiency.

Conclusion

Facing the production challenges of customized orders, PCBA factories need to address multiple aspects. By deeply understanding customer needs, optimizing production processes, strengthening technical capabilities, and effectively managing the supply chain, factories can maintain their competitiveness in customized production. Flexible production strategies and efficient execution will enable PCBA factories to remain invincible in the fiercely competitive market.

Send Inquiry

-

Delivery Service

-

Payment Options