- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to choose a factory with the appropriate production capacity for high-end PCBA processing needs?

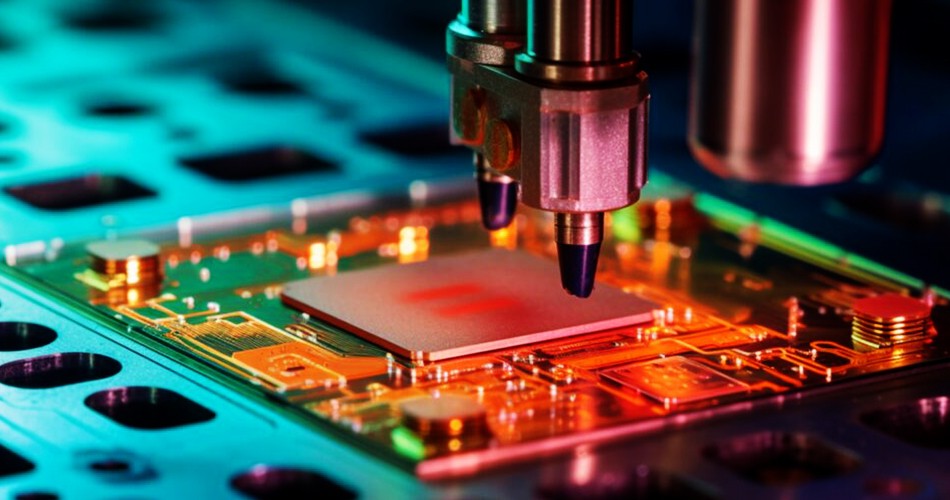

With the continuous advancement of electronic products, the demand for high-end PCBA (Printed Circuit Board Assembly) processing is increasing. When selecting a suitable factory, companies must consider the factory's production capacity and technical level to meet the stringent quality, precision, and delivery time requirements of high-end products. This article will explore how to select a PCBA processing factory with the appropriate production capacity to ensure successful product delivery.

1. Evaluating the Factory's Technical Capabilities

Advanced Equipment

When selecting a PCBA processing factory, first assess whether its equipment is advanced. High-end products typically require high-precision, high-speed production equipment to ensure product quality and reliability. You can learn about the brand, model, and technical specifications of the equipment through on-site visits or by consulting the factory's website. Furthermore, whether the factory has automated production lines is an important consideration.

Technical Expertise and R&D Capabilities

In addition to equipment, a factory's technical expertise is also crucial. Selecting a factory with strong R&D capabilities can provide innovative solutions for high-end PCBA processing. Understanding the factory's technical expertise, particularly in high-frequency, high-speed, and high-density circuit boards, will help companies find a partner that meets their needs.

2. Production Capacity and Delivery Capacity

Production Scale and Flexibility

When selecting a factory, production capacity and scale are equally important. High-end PCBA processing often requires large-scale production, so the factory's production capacity should be able to meet these requirements. Flexible production scheduling is also crucial to accommodate unexpected orders or fluctuating market demands.

Guaranteed Delivery Time

The market for high-end products is highly competitive, and fast delivery is key to success. When selecting a factory, companies should understand its delivery capabilities. By communicating with the factory and inquiring about its lead times, logistics arrangements, and emergency response capabilities, they can ensure that the factory can deliver high-quality products on time.

3. Quality Management System

Quality Certification

High-end PCBA processing has extremely stringent product quality requirements. Choosing a factory with international quality certifications (such as ISO 9001 and IATF 16949) ensures that its production processes adhere to international standards. Certified factories typically have more stringent quality control measures, effectively reducing defects during production.

Quality Control Process

Understanding the factory's quality control process is also crucial. An efficient quality management system should include monitoring at every stage, from raw material procurement to production. The factory should be equipped with comprehensive quality inspection and testing equipment to ensure that each batch of products meets predetermined quality standards.

4. Cost and Cost-Effectiveness

Comprehensive Cost Analysis

When selecting a PCBA processing factory, in addition to focusing on the unit price of the product, a comprehensive cost analysis is also necessary. The manufacturing costs of high-end products include not only direct material and labor costs, but also R&D expenses, equipment depreciation, and other factors. Selecting a factory with appropriate production capacity can achieve a higher cost-effectiveness while ensuring quality.

Long-Term Partnership

Establishing a long-term partnership with a factory can further reduce costs. With a stable order flow, companies can negotiate more favorable pricing and delivery terms with the factory. Therefore, when selecting a factory, considering its history of cooperation with other customers and its reputation can also lay the foundation for future cooperation.

Conclusion

Selecting a high-end PCBA processing factory with appropriate production capacity is a complex task, involving multiple factors such as technical capabilities, production capacity, quality management, and cost. Companies should comprehensively consider these factors when selecting to ensure they choose a partner that best meets their needs. Through comprehensive factory assessments, companies can effectively reduce production risks and ensure the smooth launch of high-end products.

Send Inquiry

-

Delivery Service

-

Payment Options