- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

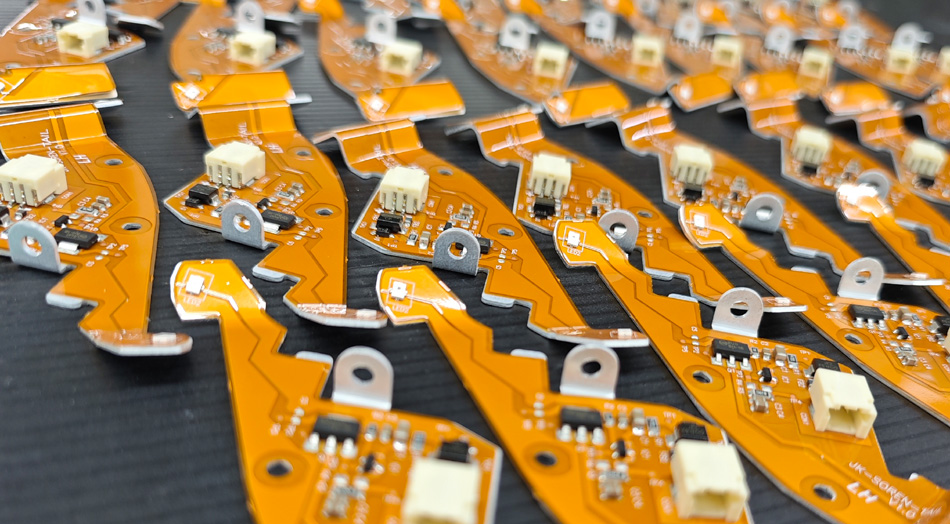

Evaluating a PCBA Factory's Manufacturing Capabilities: What Factors Affect Production Quality?

During the PCBA manufacturing process, evaluating manufacturing capabilities directly impacts the final product quality. Selecting a PCBA factory with excellent manufacturing capabilities ensures on-time project completion and guaranteed product performance meets expectations. This article will explore the key factors in evaluating a PCBA factory's manufacturing capabilities and how these factors impact production quality.

1. Modernity of Production Equipment

The Importance of High-Precision Equipment

PCBA manufacturing processes such as placement and soldering require extremely high precision. Outdated or inaccurate equipment can lead to quality issues such as component misalignment and loose soldering. Therefore, when evaluating a factory's manufacturing capabilities, it is crucial to understand whether it possesses advanced production equipment. Modern equipment not only improves production efficiency but also effectively reduces defective product rates.

The Impact of Automation Level on Quality

Automated production equipment improves consistency in the production process and reduces errors caused by human intervention. Especially in large-scale production, automated equipment ensures consistent quality across batches. Therefore, automation level is also a key criterion in evaluating a PCBA factory's manufacturing capabilities.

2. Technician Skills and Experience

The Importance of a Professional Team

Even the most advanced equipment requires experienced technicians to operate and maintain it. When evaluating a PCBA factory's manufacturing capabilities, it's crucial to understand whether the factory has a highly skilled technical team. Skilled technicians can quickly identify and resolve production issues, ensuring smooth production.

Technical Support and Continuous Improvement

A high-quality PCBA factory will continuously train its employees and improve production capacity through technology upgrades. The responsiveness and problem-solving skills of the technical support team will also impact overall production quality and efficiency.

3. Production Process Optimization

Lean Manufacturing and Process Standardization

Lean manufacturing improves efficiency and quality by reducing waste and streamlining processes. When evaluating a PCBA factory's manufacturing capabilities, it's crucial to understand whether it employs lean manufacturing philosophies and has established standardized production processes. Standardized processes ensure strict quality control at every step of production, preventing human error.

Total Quality Management System

Excellent PCBA factories typically implement a Total Quality Management (TQM) system to ensure that strict quality standards are met at every stage, from material procurement to finished product shipment. A comprehensive quality management system can help factories promptly identify and resolve potential quality issues, reducing rework and scrap.

4. Supply Chain Reliability

Raw Material Quality Control

The quality of PCBA processing depends not only on the production process but also on the quality of raw materials in the supply chain. Therefore, whether a factory conducts rigorous supplier screening and material testing is also an important factor in evaluating its manufacturing capabilities. Selecting a factory with a stable supply chain management system ensures the use of high-quality components and improves product reliability.

Supply Chain Flexibility

A PCBA processing factory's supply chain management also affects production stability and delivery times. A factory with a flexible supply chain can quickly respond to changes in market demand, reduce production delays caused by material shortages, and ensure on-time delivery of high-quality products.

5. Production Environment Management

Dust and Moisture Control Measures

In PCBA processing, the production environment has a direct impact on product quality. Especially during the soldering and assembly processes, environmental factors such as dust and humidity can degrade circuit board performance. Therefore, when evaluating a factory, pay attention to whether it has effective dust and moisture control measures to ensure that the production environment meets electronics manufacturing standards.

Static Electricity Control

Static electricity can be fatally damaging to electronic components and may cause product failures during use. Excellent PCBA manufacturers implement strict ESD protection measures within their production workshops to ensure components are protected from static electricity during processing and transportation, thereby enhancing product reliability.

6. Customer Case Studies and Market Feedback

Verification of Historical Success Case Studies

When evaluating a PCBA manufacturer's manufacturing capabilities, it's helpful to review its past success cases and customer feedback. By understanding the manufacturer's performance in similar projects, you can determine whether it has the ability to handle complex orders and ensure quality.

Long-term Customer Relationships

Long-term customer relationships are a key indicator of a PCBA manufacturer's manufacturing capabilities. Factories that maintain long-term relationships typically have stable quality management systems and excellent customer service.

Conclusion

When selecting a PCBA manufacturer, assessing its manufacturing capabilities is crucial for ensuring production quality. By examining factors such as the manufacturer's production equipment, technical team, production processes, supply chain management, and environmental controls, companies can better assess the manufacturer's overall manufacturing capabilities and ensure that the selected manufacturer can meet their product quality and delivery requirements.

Send Inquiry

-

Delivery Service

-

Payment Options