- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How can PCBA factories ensure the quality of multi-layer PCB processing?

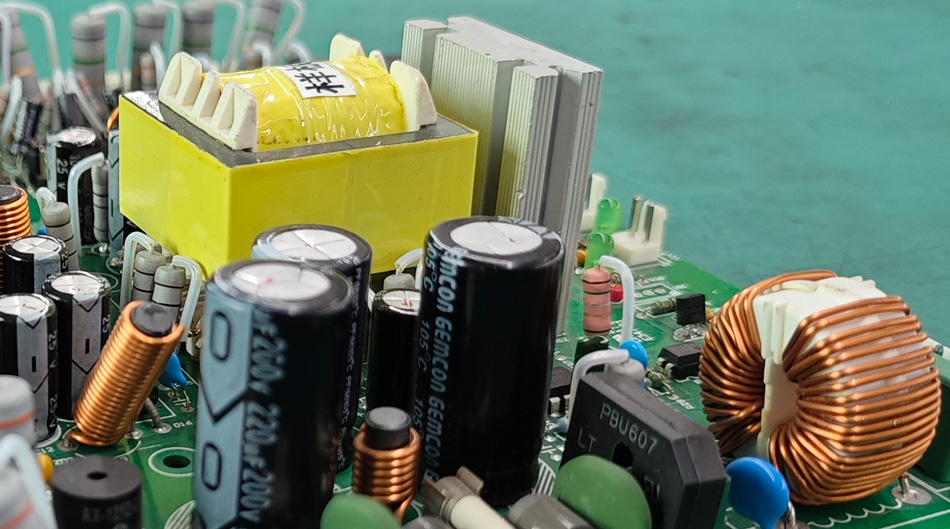

Multi-layer PCBs are an indispensable and critical component of modern electronic products. With the continuous advancement of technology, PCBA factories face higher precision and quality requirements when processing multi-layer PCBs. Ensuring the quality of multi-layer PCBs processed by PCBA not only affects product performance but also directly impacts product reliability and market competitiveness. This article will explore how PCBA factories can ensure high-quality multi-layer PCB processing through various strategies and technical means.

1. Optimizing Quality Control During the Design Phase

Design Specifications for Multi-Layer PCBs

Ensuring the quality of multi-layer PCB processing at PCBA factories begins with the design phase. Factories should strictly adhere to industry design specifications to ensure that the layout and stackup of each layer meet electrical performance and heat dissipation requirements. Advanced Design for Manufacturability (DFM) audits enable factories to proactively identify design issues that may affect processing quality and optimize them before processing.

Designing for Interlayer Connection Reliability

The quality of multi-layer PCB processing depends largely on the reliability of interlayer connections. Factories should ensure strict via design to avoid excessive or insufficient vias that could impact the electrical performance of the board. Proper via design not only improves the overall reliability of the PCB but also ensures stable signal transmission.

2. Precision Production Process and Equipment

Precise Control of the Lamination Process

The core process of multilayer PCBs is lamination, which involves stacking different layers of copper foil and insulation material together to form a single unit. Control of the lamination process is crucial to ensuring the structural strength and electrical performance of the multilayer PCB. PCBA factories require advanced lamination equipment and strictly control parameters such as temperature, pressure, and time to ensure that each layer is evenly bonded and prevent defects such as delamination and bubbles.

High-Precision Drilling Technology

Multilayer PCB production involves a large number of drilling operations, especially when drilling vias. The accuracy of the holes directly affects the electrical connection performance between boards. PCBA factories should use high-precision CNC drilling equipment and regularly calibrate the equipment to ensure the precise size and placement of each via.

3. Strict Inspection Methods and Quality Management

Optical and X-ray Inspection

To ensure the quality of multilayer PCB production, factories must use advanced inspection methods. At every stage of production, automated optical inspection (AOI) can be used to check the integrity of circuits and the accuracy of solder joints, while X-ray inspection (AXI) can penetrate deep into internal structures to ensure the reliability of connections at each layer. These inspection methods help factories quickly identify defects during production and make timely corrections, preventing problems from accumulating in the final product.

Electrical Performance Testing

The final quality assessment of multilayer PCBs requires electrical performance testing. PCBA manufacturers should use methods such as functional testing (FCT) and flying probe testing to ensure the stable electrical performance of the PCB in actual applications. Especially in scenarios involving complex circuits and high-frequency signal transmission, rigorous electrical performance testing can effectively prevent problems such as signal interference and short circuits.

4. Use High-Quality Raw Materials

High-Quality Substrates and Copper Foil

In the production of multilayer PCBs, the quality of the substrate materials and copper foil used directly affects the performance and durability of the final product. PCBA manufacturers should select high-quality material suppliers with international certifications to ensure that the materials have excellent heat resistance, insulation, and conductivity. High-quality raw materials can significantly improve product reliability, especially when operating in extreme environments such as high temperatures and high pressures.

Selecting High-Performance Solder

Soldering quality is another critical factor in multi-layer PCB manufacturing. Using high-performance lead-free solder ensures solder joint strength and corrosion resistance, thereby enhancing the lifespan and stability of the PCB. Excellent PCBA manufacturers typically conduct rigorous solder quality inspections to ensure that each batch meets production requirements.

5. Comprehensive Quality Management System

ISO Quality Management Certification

A PCBA manufacturer's quality management system is fundamental to ensuring the quality of multi-layer PCB manufacturing. Certifications such as ISO9001 enable manufacturers to establish standardized production processes and quality control systems, ensuring that every step, from design to production, meets industry standards.

Continuous Improvement and Feedback Mechanism

To continuously improve the quality of multi-layer PCB manufacturing, manufacturers need to establish a continuous improvement mechanism and regularly optimize production processes and equipment. By promptly collecting customer feedback, manufacturers can identify potential quality issues and make quick adjustments to prevent similar problems in future production.

Conclusion

Ensuring the quality of multi-layer PCBs in PCBA manufacturing requires comprehensive efforts across multiple aspects, including design, production, material selection, testing, and quality management. Through advanced process equipment, rigorous testing methods, and a comprehensive quality management system, PCBA factories are able to effectively improve the processing quality of multi-layer circuit boards, thereby providing customers with higher-performance and more reliable products. In a highly competitive market, factories can only win the trust and long-term cooperation of customers by prioritizing quality.

Send Inquiry

-

Delivery Service

-

Payment Options