- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Use Capacity Assessment Tools to Select the Best PCBA Factory?

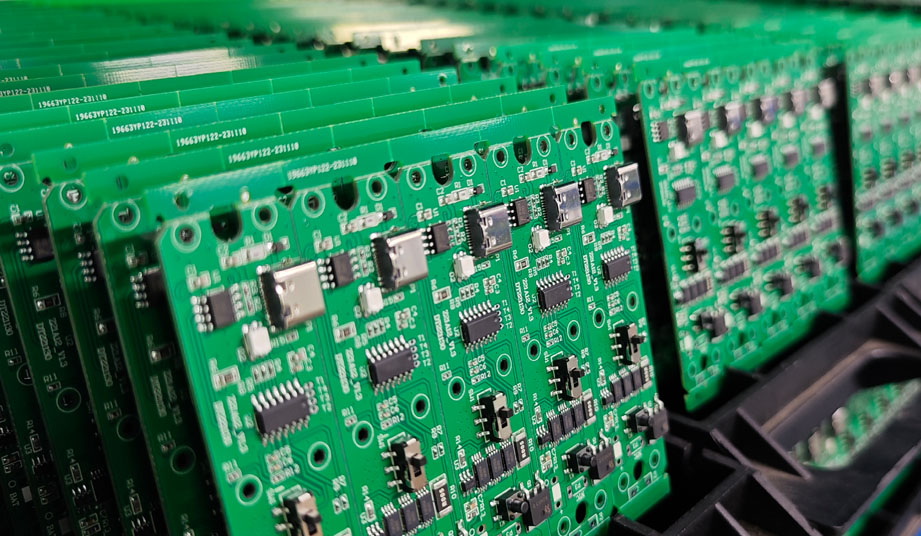

PCBA (Printed Circuit Board Assembly) processing plays a crucial role in the modern electronics manufacturing industry. Choosing the right PCBA factory not only impacts product quality and production efficiency but also directly impacts a company's market competitiveness. To ensure the selected factory can meet project requirements, it's crucial to conduct a comprehensive assessment using a capacity assessment tool. This article will explore how to use a capacity assessment tool to select the best PCBA factory.

1. Understanding the Importance of Capacity Assessment Tools

Ensuring Production Capacity

Capacity assessment tools help companies quantify the production capacity of a PCBA factory. These tools provide data on factory equipment, staffing, production processes, and other aspects, helping companies determine whether a factory has the capacity to meet specific order requirements. Selecting a factory with sufficient capacity can avoid production delays that could impact product delivery timelines.

Identifying Potential Risks

Capacity assessments can help companies identify potential risk points. For example, some factories may face capacity constraints during certain seasons. With this information, companies can take measures to mitigate risk, such as scheduling production in advance or selecting alternative factories.

2. Select Appropriate Evaluation Metrics

Modernity of Production Equipment

When selecting a PCBA factory, it is crucial to understand the modernization of its production equipment. Modern equipment generally offers higher production efficiency and better quality. Capacity assessment tools should include an assessment of equipment type, brand, and maintenance records.

Personnel Skills and Experience

The skills and experience of a factory's personnel are also crucial evaluation criteria. Skilled technicians can effectively improve production efficiency and product quality. By assessing the factory's employee training, technical certifications, and past project experience, companies can determine whether the factory has a professional team supporting them.

3. Evaluate Production Processes and Management Systems

Optimization of Production Processes

Evaluating whether a factory's production processes are optimized directly impacts production efficiency and cost control. Capacity assessment tools should analyze whether the factory's production processes are streamlined and whether it utilizes lean manufacturing and other advanced management concepts to reduce scrap and improve delivery efficiency.

Strength of the Management System

A robust management system is crucial for ensuring stable production. Companies should assess whether the factory's quality management system is comprehensive and whether it holds international certifications such as ISO. These indicators can be used to assess the standardization and stability of a factory's production process.

4. Consider Delivery Capacity and Flexibility

Delivery Capacity Reliability

In a rapidly changing market environment, delivery reliability is particularly important. Companies can use capacity assessment tools to understand a factory's historical delivery records and assess its delivery capabilities during peak periods. Reliable delivery capabilities not only meet customer needs but also enhance a company's market reputation.

Flexibility

Faced with diverse market demands, the flexibility of a PCBA factory is crucial. Companies should assess how quickly a factory responds to changes in orders during the production process and whether it can quickly adjust production plans to meet individual customer needs.

5. Real-World Case Studies

Data-Driven Decision-Making

Through case studies, companies can more intuitively understand the practical application of capacity assessment tools. For example, when selecting a PCBA factory, an electronics manufacturer used a capacity assessment tool to carefully compare the production equipment, personnel skills, and management systems of multiple factories. They ultimately selected a factory with advanced equipment and an excellent team, ensuring the successful delivery of the project.

Continuous Monitoring and Feedback

After selecting a PCBA factory, companies should regularly utilize capacity assessment tools for continuous monitoring and feedback, identifying issues and making adjustments promptly. This dynamic management approach will help maintain a positive partnership with the factory and ensure long-term success.

Conclusion

Selecting the optimal PCBA factory is a systematic decision-making process, and the use of capacity assessment tools can provide companies with robust data support. By selecting appropriate evaluation indicators, thoroughly analyzing production processes and management systems, and focusing on delivery capabilities and flexibility, companies can more effectively select the right PCBA factory for their needs and enhance their market competitiveness. As industry competition intensifies, effectively utilizing capacity assessment tools will become a crucial factor for business success.

Send Inquiry

-

Delivery Service

-

Payment Options