- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does the industrial upgrading of PCBA factories promote industry change?

2025-06-07

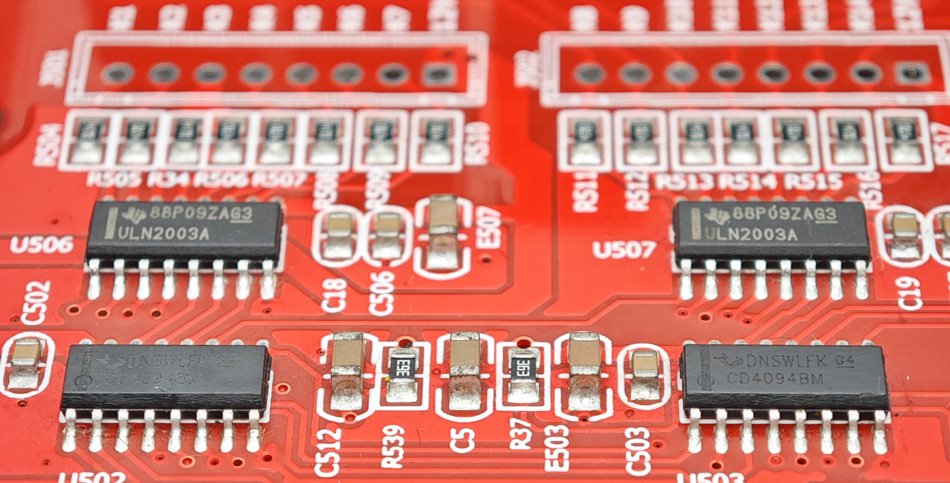

With the rapid development of science and technology, the PCBA (Printed Circuit Board Assembly) industry has undergone many major changes worldwide. Industrial upgrading is not only a key means for PCBA factories to enhance their competitiveness, but also an important factor in promoting innovation and transformation of the entire industry. This article will explore how the industrial upgrading of PCBA factories can promote industry change.

1. Leading the trend of intelligent manufacturing

In recent years, with the continuous development of emerging technologies such as artificial intelligence (AI) and the Internet of Things (IoT), the industrial upgrading of PCBA factories has gradually entered the stage of intelligent manufacturing. By introducing intelligent production lines, automated equipment and big data analysis, PCBA factories are able to realize the automation, digitization and intelligence of the production process. This transformation not only improves production efficiency and reduces manual intervention, but also effectively improves the accuracy and reliability of production. For example, intelligent welding and testing equipment can quickly detect defects in production, thereby reducing human errors and improving product quality and consistency.

The popularity of intelligent manufacturing has promoted innovation in the PCBA processing industry and improved overall productivity. This not only meets the market demand for efficient and high-quality products, but also injects new vitality into the entire industry.

2. Green environmental protection promotes sustainable development

With the increasingly stringent environmental regulations and the increasing social requirements for sustainable development, PCBA factories pay attention to the application of green manufacturing and environmental protection technologies in the process of industrial upgrading. Many leading PCBA factories have reduced energy consumption and waste emissions in the production process by improving production processes, using environmentally friendly materials, and implementing waste recycling, which has promoted the popularization of green manufacturing.

This transformation not only enables PCBA factories to comply with increasingly stringent environmental regulations, but also allows the entire industry to move towards sustainable development. Environmental protection is not only a manifestation of corporate social responsibility, but also a key factor in enhancing brand competitiveness. Choosing a PCBA factory that meets environmental standards can attract more environmentally conscious customers and investors and promote the green upgrade of the industry.

3. Flexible production promotes personalized customization

With the diversification of market demand, especially the rapid renewal of electronic consumer products, the traditional production model can no longer meet customers' needs for customization and small batches and multiple varieties of products. PCBA factories have introduced flexible production lines through industrial upgrading to achieve high flexibility and personalized customization in production. This means that PCBA factories can respond quickly to market changes and support the transition from single-piece customization to large-scale production.

Flexible production not only improves the production capacity of PCBA processing, but also enables factories to better meet the personalized needs of customers. For example, customers can customize the wiring method, component selection and board type of circuit boards according to their own design requirements, which greatly improves customers' production efficiency and market competitiveness.

4. Technological innovation promotes product upgrades

The industrial upgrading of PCBA factories has brought about a technological leap. From traditional production methods to today's automated and intelligent production equipment, technological innovation has become the core driving force for the transformation of the entire industry. The factory has improved the accuracy and efficiency of PCBA processing by continuously introducing new technologies such as 3D printing, laser welding, and AI visual inspection.

This technological innovation not only speeds up the product R&D cycle and shortens the time to market, but also promotes the rapid emergence of new products and new applications. With the continuous advancement of technology, PCBA factories can produce higher-performance electronic products to meet the needs of high-quality and high-performance products in different fields, thereby promoting technological progress in the entire industry.

5. Data management improves decision-making efficiency

Another key trend in industrial upgrading is the application of big data and cloud computing technologies. PCBA factories have achieved data management in production data, quality monitoring, inventory management and other aspects by integrating big data analysis and cloud platforms. This enables factories to monitor production in real time, accurately predict production needs, optimize inventory management and resource allocation, and improve overall production efficiency.

Through data management, PCBA factories can discover potential problems in real time during the production process, make timely adjustments, reduce waste, and improve the operating efficiency of the production line. In addition, big data technology also helps factories to accurately predict customer needs, thereby achieving more personalized and customized services.

Summary

The industrial upgrading of PCBA factories is not only a demand for their own development, but also a key force to promote the transformation of the entire industry. Through intelligent manufacturing, green environmental protection, flexible production, technological innovation and data management, PCBA factories are moving towards a more efficient, environmentally friendly and customized direction. These changes have not only improved the factory's own production capacity and service level, but also promoted the overall progress of the PCBA processing industry, enabling it to better adapt to rapidly changing market needs and enhance the industry's international competitiveness. With the continuous deepening of industrial upgrading, the future PCBA processing industry will be more intelligent, green and efficient, which brings new development opportunities for the entire electronics manufacturing industry.

-

Delivery Service

-

Payment Options