- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Exploring the differences in technology and services among global PCBA factories

2025-06-09

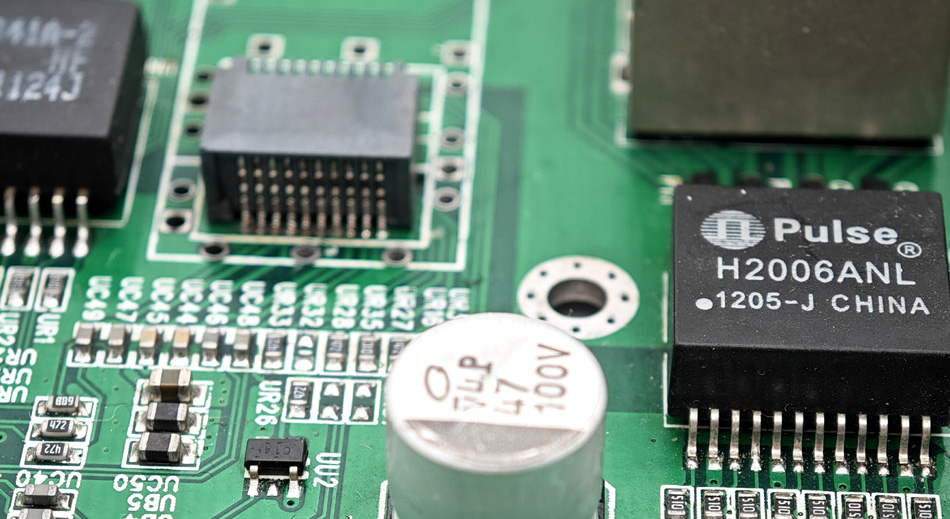

With the advancement of globalization, the PCBA (Printed Circuit Board Assembly) industry is facing increasingly fierce competition. The differences in technology and services among global PCBA factories have become an important consideration for companies when choosing partners. PCBA factories in different regions may have a direct impact on customers' choices due to differences in technology level, production capacity, service model, etc. This article will explore the differences in technology and services among global PCBA factories and how these differences affect customers' decisions.

1. Technology differences: the level of technological development between regions

The differences in technology levels among PCBA factories in different regions are mainly reflected in the degree of automation, process innovation, and the advancement of production equipment.

PCBA factories in Asia, especially in China and Taiwan, have accumulated rich production experience and technical advantages for a long time. Many factories are able to provide advanced production technologies, such as high-speed surface mount technology (SMT), precision soldering processes, and automated inspection systems, which enable these factories to handle high-complexity and high-precision PCBA processing tasks.

In contrast, some PCBA factories in Europe and the United States pay more attention to technological innovation and green manufacturing, especially in terms of environmental protection, and have stricter requirements. Some factories in Europe are leading in energy conservation and emission reduction, the use of environmentally friendly materials, etc., and they are also leading the trend of intelligent manufacturing and actively promoting the application of Industry 4.0 technology.

2. Production capacity differences: supply chain and delivery time

The production capacity differences of global PCBA factories directly affect customers' supply chain management and delivery time. PCBA factories in Asia, especially China, usually have strong production capacity and flexible production scheduling. With their scale effect and sufficient labor resources, many factories are able to provide efficient production services at a lower cost, especially suitable for large-scale production orders. Many PCBA factories in China can respond quickly to customer needs and shorten delivery cycles through flexible production scheduling.

Relatively speaking, PCBA factories in Europe and the United States tend to focus on high-precision, high-value-added products and small-batch customized orders. Although the production capacity of these factories is relatively sophisticated, due to the limitations of labor costs and production scale, they may not be able to meet the needs of large-scale production like Asian factories. European and American factories rely more on advanced production equipment and processes to ensure high-quality output.

3. Service differences: customer support and customization capabilities

PCBA processing is not just a production process, but also includes all aspects of customer service. The service differences of global PCBA factories are reflected in customer support, after-sales service and customization capabilities.

Asian factories usually offer competitive prices and flexible customization services to meet the needs of most customers, especially for fast delivery and small batch orders. Many Chinese factories have established a complete customer service system, which can provide customers with one-stop services such as technical support, quality inspection and logistics management.

However, PCBA factories in Europe and the United States tend to pay more attention to high-end customization and all-round technical support, especially in the fields of high technology and high precision, their customized services are often more meticulous. The after-sales service of European and American factories is also more professional, especially in the early stage of product development and production process, they can provide higher-level technical consultation and solution optimization to help customers solve complex design and technical problems.

4. Compliance and quality control: standards and certification

Compliance and quality control are important factors that cannot be ignored in global PCBA factories. PCBA factories in different regions have different quality control and compliance requirements due to the influence of different laws, regulations and industry standards.

PCBA factories in Europe and North America usually strictly follow international quality management systems such as ISO9001 and ISO14001, and maintain high compliance with environmental regulations such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment). This makes these factories outstanding in environmental protection and sustainable development, especially suitable for customers with strict environmental protection requirements.

In China and Southeast Asia, many PCBA factories have begun to align with international standards and have obtained similar quality certifications. Despite this, some factories still have gaps in compliance and quality control, especially in details and long-term product stability, which may not be as rigorous as European and American factories.

Summary

The differences in technology and services of global PCBA factories require customers to make trade-offs based on their own needs when choosing partners. Asian factories are suitable for large-volume orders and fast delivery with their lower production costs and efficient production capacity. European and American factories have advantages in technological innovation, quality control and personalized services, and are suitable for customers who require high-precision, high-value-added products. Therefore, when choosing a suitable PCBA processing factory, we should not only consider basic factors such as price and delivery time, but also comprehensively consider the factory's technical strength, service capabilities, quality control and compliance. Through a comprehensive analysis of these differences, companies can make more informed decisions and achieve the best balance between product quality and cost control.

-

Delivery Service

-

Payment Options