- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How PCBA factories can improve project success rates through full-process management

2025-06-06

In the process of PCBA (Printed Circuit Board Assembly) processing, full-process management is one of the key factors to ensure project success. Through efficient full-process management, PCBA factories can not only improve production efficiency, but also improve product quality, reduce costs, and enhance customer satisfaction. This article will explore how PCBA factories can improve project success rates through full-process management.

1. Definition and importance of full-process management

Full-process management refers to the effective management and control of each link in all stages of PCBA processing, from design, procurement, production to testing and delivery. By optimizing processes, improving coordination and information transparency, full-process management can minimize risks, improve project predictability, and thus increase success rates.

In PCBA processing, mistakes in any link may lead to project delays, cost increases or quality problems. Therefore, a comprehensive management system can effectively prevent these problems from occurring.

2. Project demand analysis and planning

The first step of full-process management is to deeply analyze and plan customer needs. At the beginning of the project, PCBA factories need to fully communicate with customers to understand their specific requirements and expected goals. The key task of this stage is to ensure that all parameters, specifications and quality standards in the design and production process are clearly defined and recorded.

By accurately grasping the needs, the factory can better plan the production process, optimize resource allocation, identify possible technical problems in advance, and reduce the risk of rework and modification in the later stage.

3. Accurate supply chain management

The success of PCBA processing is inseparable from efficient and accurate supply chain management. From component procurement to component acceptance, every link is crucial. Efficient supply chain management can ensure the timely supply of raw materials, quality control of components and effective cost control.

Through full process management, the factory can establish a close cooperative relationship with suppliers to ensure that the required components are delivered on time, according to quality and quantity, and avoid project delays or quality problems caused by raw material problems.

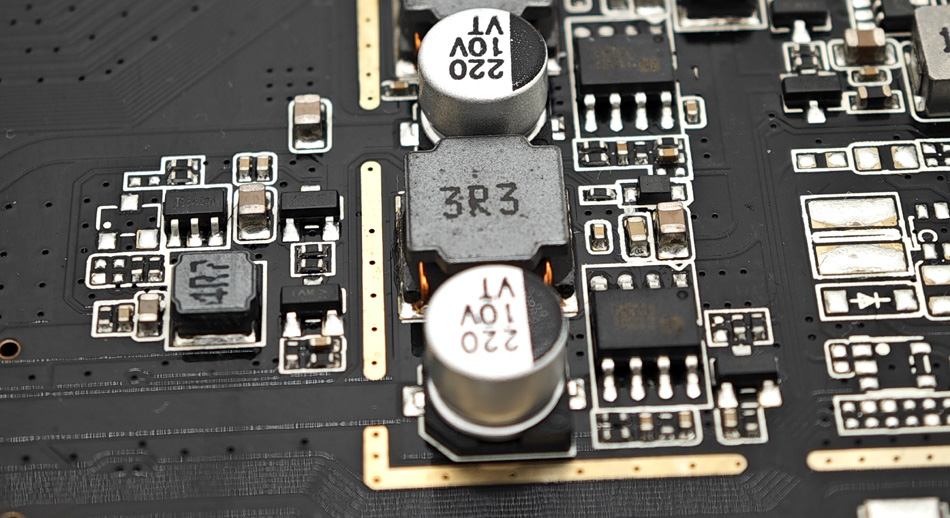

4. Refined production process control

In the production process, PCBA factories need to finely control the production process, including welding, patch, testing and other links. By using automated equipment, strict quality control standards and real-time data tracking systems, factories can monitor the progress of each process in real time to ensure that production quality and progress are not disturbed.

In addition, the factory can use quality management tools such as Six Sigma and FMEA (Failure Mode and Effect Analysis) to identify potential risk points and take measures in advance to reduce the probability of errors in the production process.

5. Rigorous testing and verification

In the process of PCBA processing, the testing link is particularly critical. Through full-process management, the factory can perform necessary testing and verification at each production stage to ensure that the product meets the design requirements. Including visual inspection, functional testing, electrical testing, and high and low temperature cycle testing, etc., can ensure the quality stability of the final product.

Through comprehensive test data analysis, the factory can quickly discover potential problems and make corrections to avoid quality failures after large-scale production.

6. Customer feedback and continuous improvement

After the project is delivered, customer feedback is a valuable improvement opportunity for the factory. Through full-process management, PCBA factories can efficiently collect and analyze customer feedback and promptly discover deficiencies and room for improvement in the production process. This can not only optimize the follow-up work of the current project, but also provide improvement plans for future projects.

Establishing a good customer feedback mechanism and combining it with data analysis tools can help factories improve customer satisfaction and enhance market competitiveness.

Summary

By implementing full-process management, PCBA factories can effectively improve the success rate of projects. In the refined management of each link, the factory can predict and respond to problems in advance, reduce production risks, and ensure the timely delivery of high-quality products. With the continuous improvement of technology and management level, the full-process management of PCBA factories will become an important guarantee for corporate competitiveness, providing customers with more efficient and accurate services and promoting industry development.

-

Delivery Service

-

Payment Options