- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Technology comparison and cooperation opportunities of global PCBA factories

2025-06-05

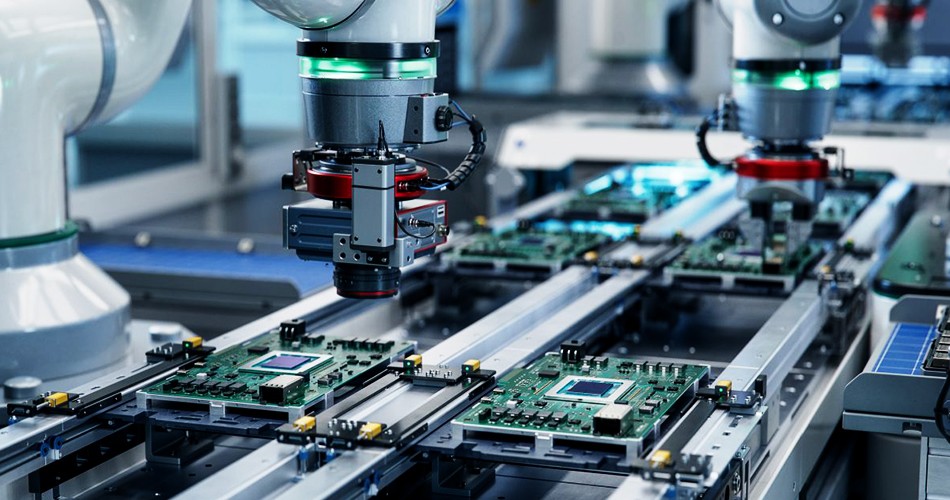

With the rapid development of the global electronics industry, PCBA (Printed Circuit Board Assembly) factories have continuously made breakthroughs and innovations in technology. PCBA factories in different countries and regions have certain differences in technology level, production capacity and service model. This article will compare the technology of global PCBA factories and explore cooperation opportunities between factories in various countries.

1. Technological advantages of the Asian market

Asia is the main production base for PCBA processing in the world. Among them, the technology level of PCBA factories in China, South Korea, Japan and Taiwan is in a leading position. Especially in China, PCBA factories generally use advanced automation equipment and intelligent production lines, which can efficiently complete large-scale production. The low labor cost and strong supply chain integration capabilities of Chinese factories make them occupy an important position in the global market.

In terms of technological innovation, PCBA factories in Taiwan and Japan tend to pay more attention to precision and high reliability, especially in the production of high-frequency and high-precision circuit boards, and have unique technical advantages. PCBA factories in South Korea are at the forefront of automated production and technology research and development, using high-end technology equipment to achieve efficient and low-cost production.

2. Technical characteristics of North America and Europe

Compared with production bases in Asia, PCBA factories in North America and Europe focus more on technological innovation and customized product services. PCBA factories in the United States and Germany usually use high-end testing equipment and automated production lines to produce high-precision electronic products that meet strict quality standards. Especially in the fields of medical electronics, automotive electronics, etc., factories in North America and Europe have the production capacity of technologically advanced and high value-added products.

In addition, PCBA factories in North America and Europe pay more attention to environmental protection and green manufacturing. With the increasingly stringent environmental regulations, PCBA factories in these regions have higher technical requirements and compliance standards in waste management, energy efficiency and hazardous substance control.

3. Potential for technological improvement in developing countries

PCBA factories in developing countries such as India, Vietnam, and Brazil have also made significant technological progress in recent years. Factories in these regions have significant advantages in low-cost production and large-scale manufacturing, and have gradually attracted the outsourcing needs of many global companies. With the continuous improvement of local technical levels, especially in the fields of intelligent manufacturing and automated production, PCBA factories in developing countries are expanding to the high-end market.

For example, Indian PCBA factories have strong R&D capabilities in the application of artificial intelligence and IoT devices, and have gradually become one of the global production bases for electronic products. Vietnam has become an important supplier of international brands with its flexible production capacity and cost advantages.

4. Potential opportunities for global cooperation

The technological differences between global PCBA factories have created abundant opportunities for cross-border cooperation. In terms of technological innovation, Asian factories can cooperate with North American and European manufacturers to learn high-end testing and assembly technologies, while improving overall production efficiency through the integration of global supply chains. For example, Asian factories can provide low-cost production services to North American and European customers, while North American and European factories can provide technical support and high-end equipment to help Asian factories improve their production capacity and product quality.

In addition, with the acceleration of globalization, cross-border cooperation can not only share technological advantages, but also take advantage of the resource advantages of various regions to reduce production costs. Especially in flexible production, intelligent manufacturing and environmentally friendly manufacturing, the cooperation of PCBA factories in various countries will be able to promote technological progress and promote the sustainable development of the industry.

Summary

The technological differences and production characteristics of global PCBA factories provide abundant opportunities for international cooperation. The low-cost advantages of Asian factories, the high-tech level of North America and Europe, and the growth potential of developing countries have brought new cooperation opportunities to the global PCBA market. In the future, with the further integration of the global supply chain and the continuous advancement of technological innovation, cooperation between PCBA factories will promote the progress of the industry and enhance the competitiveness of the global market. When choosing PCBA processing partners, companies should choose partners with technological innovation, production capacity and cost advantages according to the needs of different markets, achieve technical complementarity and resource sharing, and promote the common development of the global electronics industry.

-

Delivery Service

-

Payment Options