- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How does inventory management of PCBA factories affect the delivery cycle?

2025-05-31

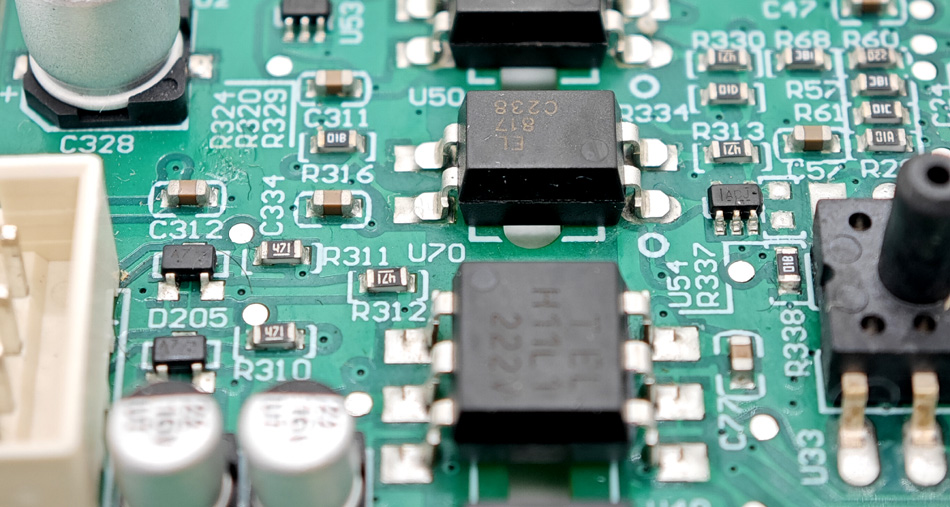

In the modern PCBA (Printed Circuit Board Assembly) processing process, inventory management is one of the important factors affecting the delivery cycle. The efficiency and accuracy of inventory management directly affect the smoothness of production, the timeliness of delivery and customer satisfaction. Therefore, when formulating production plans, PCBA factories need to finely control inventory management to ensure stable and efficient material supply in each link. This article will explore how inventory management of PCBA factories affects the delivery cycle and provide some suggestions for optimizing inventory management.

1. The impact of inventory management on material supply

PCBA processing requires a large number of electronic components and raw materials. Material shortages in any link may cause delays in production progress. The quality of inventory management directly determines whether these materials can be in place in time. Under an efficient inventory management model, PCBA factories can ensure that all required materials are fully prepared in advance to avoid production stagnation due to shortages.

For example, with a sophisticated material requirement planning (MRP) system, the factory can accurately estimate the amount of raw materials required in the future based on production orders and sales forecasts, so as to purchase and reserve in advance. This advance preparation can not only ensure the timely supply of materials, but also effectively reduce production delays caused by material shortages.

2. The impact of inventory management on the production process

Good inventory management can optimize the production process and reduce downtime caused by insufficient materials. When the PCBA factory can accurately grasp the inventory status of each component, production scheduling and work arrangements can be more efficient. A reasonable inventory management model can ensure that the production line does not stagnate due to lack of materials, thereby shortening the entire production cycle.

For example, in a PCBA factory that implements the Lean Manufacturing model, the factory will replenish inventory in real time according to actual production needs instead of over-stocking materials. By reducing inventory backlogs, PCBA factories can maintain the smoothness of the production line, reduce capital occupation, and thus improve overall production efficiency.

3. The direct impact of inventory management on the delivery cycle

Improper inventory management may cause materials to be unable to be supplied on time, thereby affecting production progress and ultimately extending the delivery cycle. Especially in the production of large-volume orders, once inventory is insufficient, procurement, transportation and warehousing may take more time. This not only increases production costs, but may also cause customers to fail to receive products on time.

To avoid this situation, PCBA factories can adopt a more flexible inventory management method. For example, adopt a "safety stock" strategy to ensure that there is always a certain amount of stock in the inventory to cope with sudden fluctuations in material demand. In this way, even if there is a short interruption in the material supply chain, the factory can still maintain the continuity of production and avoid delays in the delivery cycle.

4. The role of real-time monitoring and data management

Modern inventory management does not only rely on manual estimation, but also monitors in real time through data-based means. PCBA factories can track inventory status and material flow in real time through software such as ERP (Enterprise Resource Planning) system and WMS (Warehouse Management System) to ensure real-time docking of production demand and inventory.

Through these systems, factories can promptly identify potential problems in inventory and take corresponding measures to adjust them. For example, if a certain component is out of stock, the system can immediately generate a purchase order and issue an alarm, avoiding the impact of production progress due to failure to discover the problem in time.

Summary

There is a close relationship between inventory management and delivery cycle in PCBA factories. Refined inventory management can ensure the timely supply of materials and optimize production processes, thereby shortening delivery cycles and improving production efficiency. In the highly competitive market, customers pay more and more attention to the timeliness of delivery, so PCBA factories must continuously optimize inventory management to ensure smooth and efficient production to meet customer delivery needs.

-

Delivery Service

-

Payment Options