- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Evaluating the impact of the PCBA factory's operating model on product success

2025-06-02

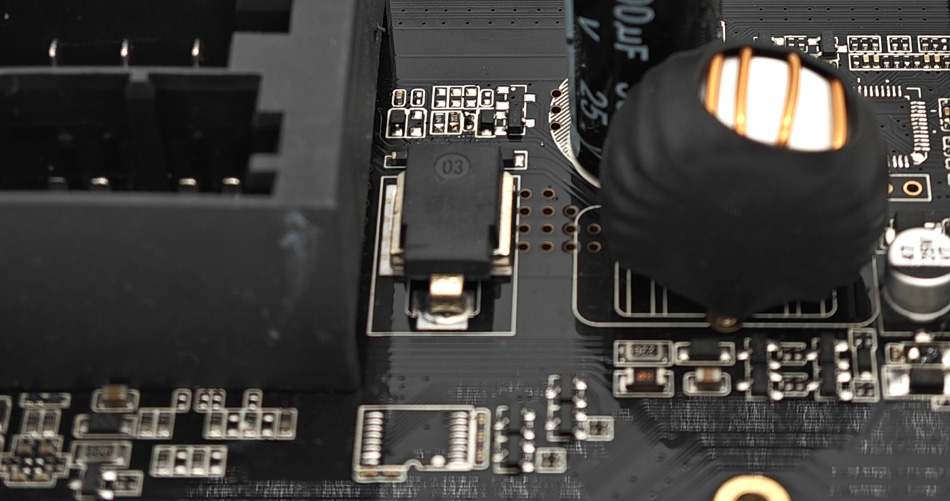

In the production process of modern electronic products, the operating model of the PCBA (Printed Circuit Board Assembly) factory is crucial to the success of the product. The PCBA factory is not just a place where products are manufactured. Its operating efficiency, production quality, supply chain management, and technical support directly affect the quality and market performance of the product. Therefore, when companies choose PCBA processing partners, they need to comprehensively evaluate the factory's operating model to ensure that the selected factory can provide efficient, flexible and reliable support during the project implementation. This article will explore how to evaluate the PCBA factory's operating model and its impact on product success.

1. The impact of the operating model on production efficiency

Production efficiency is a key factor in evaluating the operating model of a PCBA factory. An efficient production process can not only ensure on-time delivery, but also reduce production costs and improve the competitiveness of the company. PCBA processing factories can significantly improve production speed and accuracy by adopting advanced automation equipment and optimized production processes. This efficient production model can help companies achieve rapid market response and avoid missing market opportunities due to long production cycles.

For example, a PCBA factory with flexible production lines and instant scheduling systems can quickly adjust production plans according to changes in customer demand to avoid shutdowns and waste of production capacity. This is especially important for the electronics industry, which requires rapid product iteration.

2. The impact of operating models on quality control

Quality is the basis for the success of any product, especially in the PCBA processing process, where the quality of the product directly affects the stability and performance of electronic products. The operating model of the PCBA factory determines its strictness and execution in quality management. An excellent operating model is usually equipped with a comprehensive quality control system, from raw material storage, production process, to final inspection, each link is strictly checked to ensure that every circuit board produced meets the customer's quality standards.

For example, a quality management model with full tracking can monitor every detail of the production process in real time. Once a problem is found, corrective measures can be taken immediately to avoid unqualified products from entering the market. This strict quality control not only reduces the risk of rework and return, but also helps to enhance brand reputation.

3. The impact of operating models on cost management

Cost control is the key to the survival and development of any manufacturing company in the competition. The operating model of the PCBA factory affects the costs of raw material procurement, production scheduling, inventory management and other aspects. An optimized operating model can minimize production costs while ensuring quality, thereby enhancing the market competitiveness of products.

For example, through a lean production model, PCBA factories can reduce unnecessary waste and improve resource utilization. Good supply chain management can ensure the stability of raw material procurement prices and avoid production stagnation caused by material price increases or delayed supply. This cost management advantage is crucial to customer product pricing and profit margins.

4. The impact of operating models on customer communication and after-sales service

The operating model of the PCBA factory also affects the efficiency of communication with customers and the quality of after-sales service. An efficient operating model not only optimizes resources during the production process, but also improves the transparency and responsiveness of customer communication. By establishing a systematic customer relationship management (CRM) mechanism and customer feedback channels, PCBA factories can understand customer needs and problems in a timely manner and provide customized solutions.

For example, PCBA factories can maintain close contact with customers during the production process, track project progress in real time, and make adjustments quickly if problems arise. For some high-end customers, providing timely technical support and after-sales service is an important criterion for them to choose partners.

Summary

The operating model of the PCBA factory directly affects the success of the product. High production efficiency, strict quality control, sophisticated cost management and high-quality customer service are all important factors that determine whether a product can be successfully launched. When choosing a PCBA processing partner, in addition to paying attention to price and delivery time, companies should also have a deep understanding of the factory's operating model to ensure that it can provide stable and high-quality production support to help products stand out in the fiercely competitive market.

-

Delivery Service

-

Payment Options